Belt Adjustment

For optimal power transmission from the motor to the spindle, the belt must be in good condi- tion and properly tensioned. The belt should be checked for cracks, fraying and wear. Check belt tension every three months; more often if the lathe is used frequently.

Checking Belt

1.DISCONNECT LATHE FROM POWER!

2.Open the cabinet door.

3.Push the center of the belt. It should feel rigid to the touch with almost no deflection or play.

Tensioning Belt

1.DISCONNECT LATHE FROM POWER!

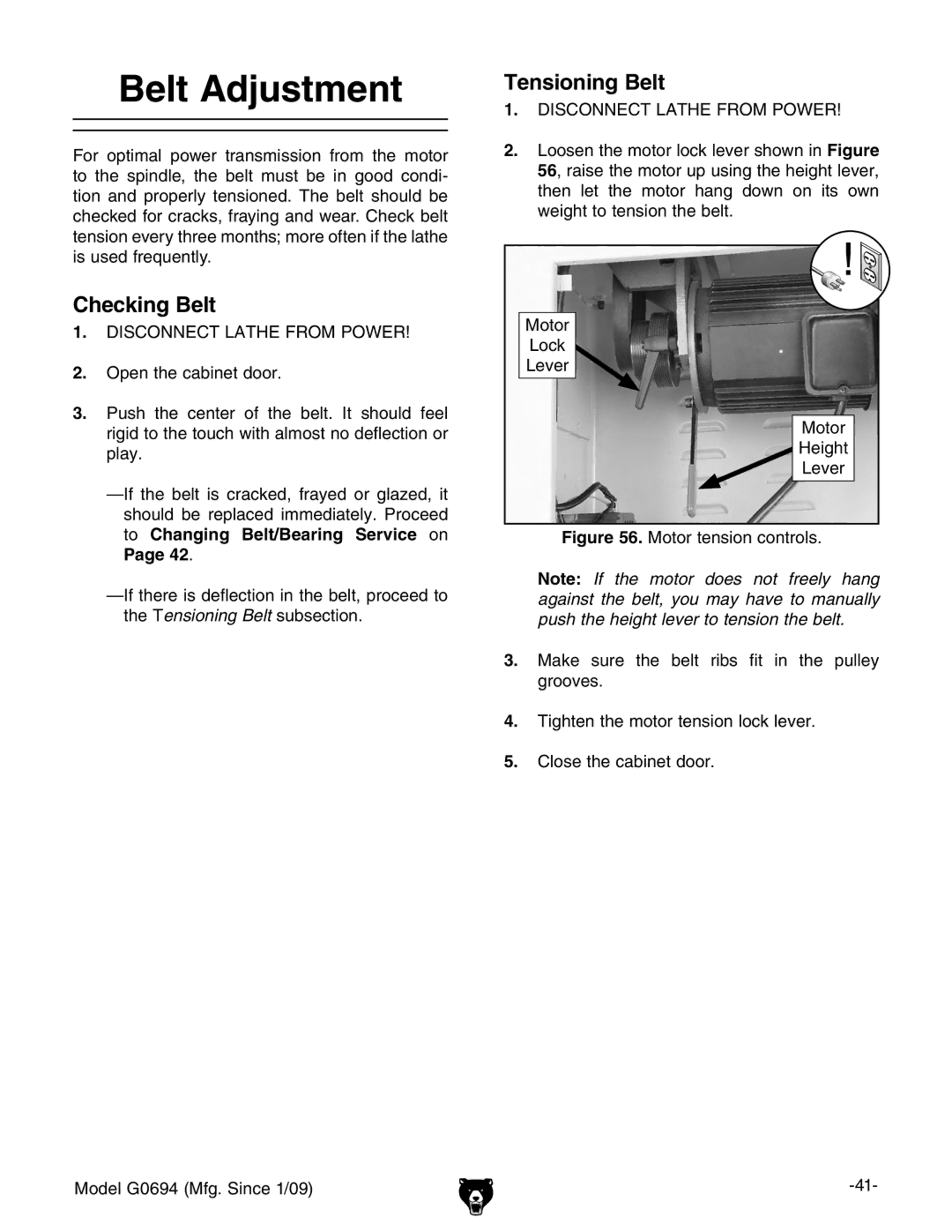

2.Loosen the motor lock lever shown in Figure 56, raise the motor up using the height lever, then let the motor hang down on its own weight to tension the belt.

Motor |

Lock |

Lever |

Motor |

Height |

Lever |

Figure 56. Motor tension controls.

Note: If the motor does not freely hang against the belt, you may have to manually push the height lever to tension the belt.

3.Make sure the belt ribs fit in the pulley grooves.

4.Tighten the motor tension lock lever.

5.Close the cabinet door.

Model G0694 (Mfg. Since 1/09) |