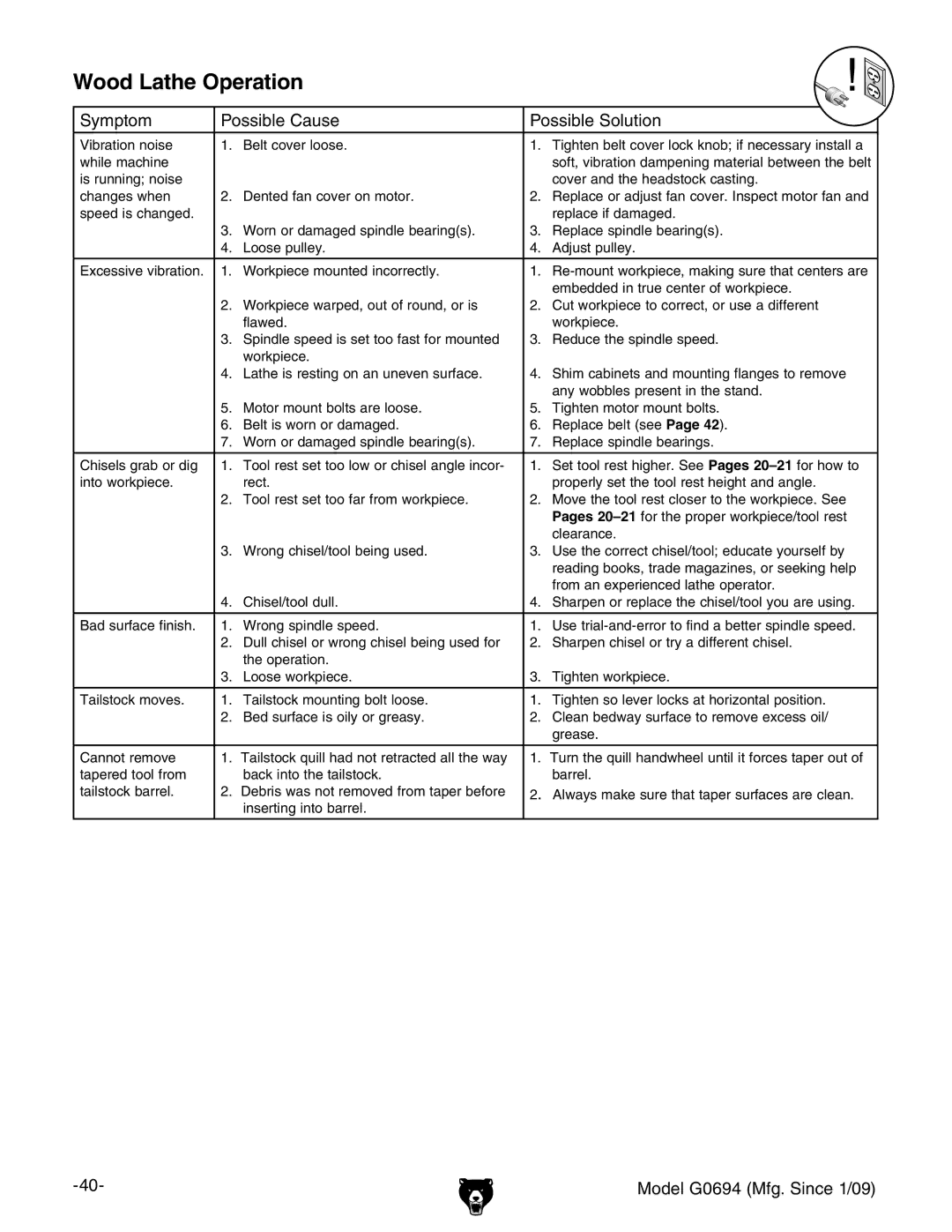

Wood Lathe Operation

Symptom | Possible Cause | Possible Solution | ||

|

|

|

|

|

Vibration noise | 1. | Belt cover loose. | 1. | Tighten belt cover lock knob; if necessary install a |

while machine |

|

|

| soft, vibration dampening material between the belt |

is running; noise |

|

|

| cover and the headstock casting. |

changes when | 2. | Dented fan cover on motor. | 2. | Replace or adjust fan cover. Inspect motor fan and |

speed is changed. |

|

|

| replace if damaged. |

| 3. | Worn or damaged spindle bearing(s). | 3. | Replace spindle bearing(s). |

| 4. | Loose pulley. | 4. | Adjust pulley. |

|

|

|

|

|

Excessive vibration. | 1. | Workpiece mounted incorrectly. | 1. | |

|

|

|

| embedded in true center of workpiece. |

| 2. | Workpiece warped, out of round, or is | 2. | Cut workpiece to correct, or use a different |

|

| flawed. |

| workpiece. |

| 3. | Spindle speed is set too fast for mounted | 3. | Reduce the spindle speed. |

|

| workpiece. |

|

|

| 4. | Lathe is resting on an uneven surface. | 4. | Shim cabinets and mounting flanges to remove |

|

|

|

| any wobbles present in the stand. |

| 5. | Motor mount bolts are loose. | 5. | Tighten motor mount bolts. |

| 6. | Belt is worn or damaged. | 6. | Replace belt (see Page 42). |

| 7. | Worn or damaged spindle bearing(s). | 7. | Replace spindle bearings. |

|

|

|

|

|

Chisels grab or dig | 1. | Tool rest set too low or chisel angle incor- | 1. | Set tool rest higher. See Pages |

into workpiece. |

| rect. |

| properly set the tool rest height and angle. |

| 2. | Tool rest set too far from workpiece. | 2. | Move the tool rest closer to the workpiece. See |

|

|

|

| Pages |

|

|

|

| clearance. |

| 3. | Wrong chisel/tool being used. | 3. | Use the correct chisel/tool; educate yourself by |

|

|

|

| reading books, trade magazines, or seeking help |

|

|

|

| from an experienced lathe operator. |

| 4. | Chisel/tool dull. | 4. | Sharpen or replace the chisel/tool you are using. |

|

|

|

|

|

Bad surface finish. | 1. | Wrong spindle speed. | 1. | Use |

| 2. | Dull chisel or wrong chisel being used for | 2. | Sharpen chisel or try a different chisel. |

|

| the operation. |

|

|

| 3. | Loose workpiece. | 3. | Tighten workpiece. |

|

|

|

|

|

Tailstock moves. | 1. | Tailstock mounting bolt loose. | 1. | Tighten so lever locks at horizontal position. |

| 2. | Bed surface is oily or greasy. | 2. | Clean bedway surface to remove excess oil/ |

|

|

|

| grease. |

|

|

|

|

|

Cannot remove | 1. | Tailstock quill had not retracted all the way | 1. | Turn the quill handwheel until it forces taper out of |

tapered tool from |

| back into the tailstock. |

| barrel. |

tailstock barrel. | 2. | Debris was not removed from taper before | 2. | Always make sure that taper surfaces are clean. |

|

| inserting into barrel. |

|

|

Model G0694 (Mfg. Since 1/09) |