Lubricating Spindle Bearings

1.DISCONNECT LATHE FROM POWER!

2.Loosen the set screws closest to the faceplate on the inboard mounting hub and remove the faceplate.

3.Loosen the set screws on the inner face of the mounting hub, as shown in Figure 47, then remove the mounting hub.

Faceplate |

Mounting |

Hub |

Figure 47. Loosening set screws on inboard

mounting hub.

4.Place a few rags inside the headstock against the inner side of the bearing to catch any grease and debris for the next step.

5.Wipe down the outer race of the roller bear- ing with a clean cloth to remove any grime or debris.

6.Use a brush, mineral spirits, and an air gun to remove old grease from the bearing until it is clean and dry.

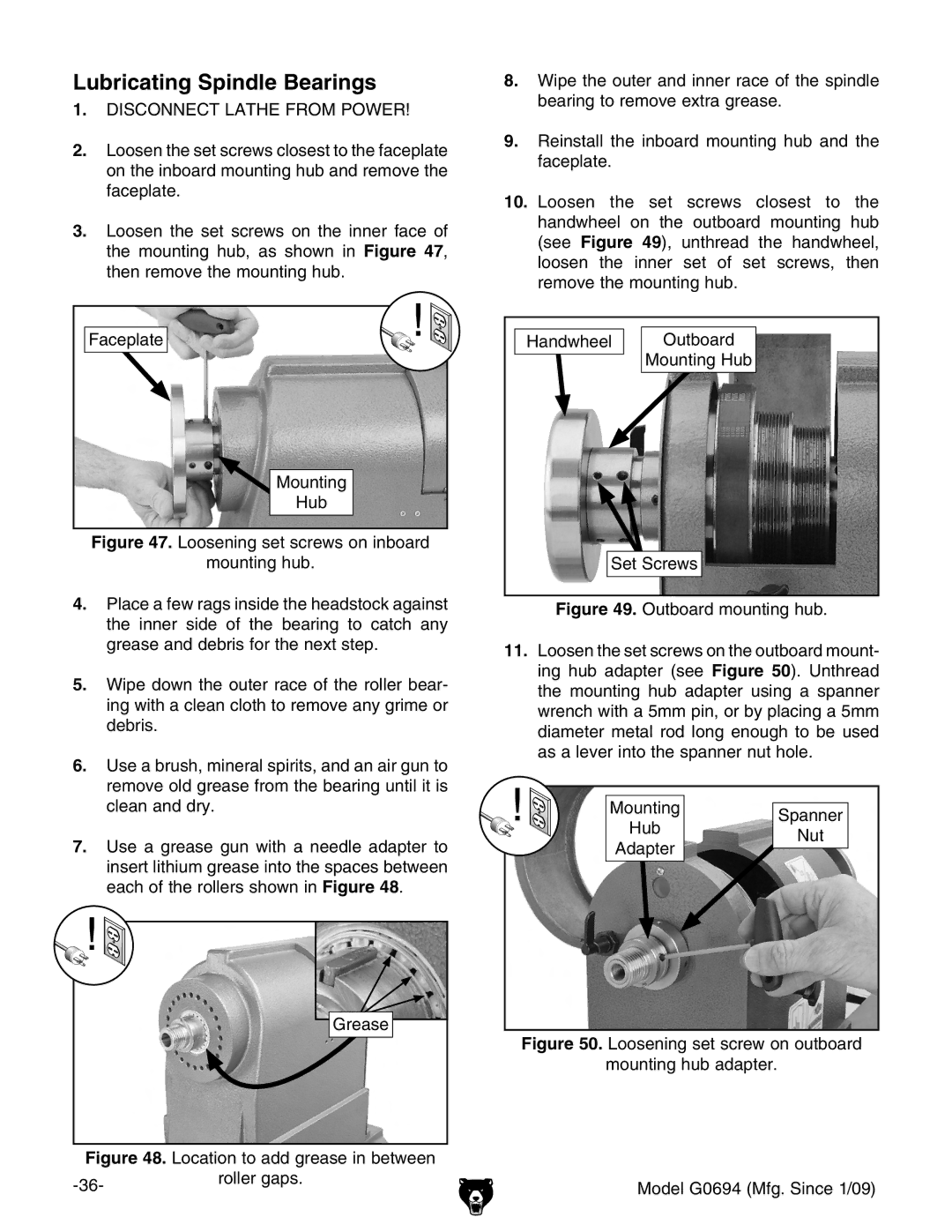

7.Use a grease gun with a needle adapter to insert lithium grease into the spaces between each of the rollers shown in Figure 48.

Grease

Grease

Figure 48. Location to add grease in between

roller gaps. | |

|

8.Wipe the outer and inner race of the spindle bearing to remove extra grease.

9.Reinstall the inboard mounting hub and the faceplate.

10.Loosen the set screws closest to the handwheel on the outboard mounting hub (see Figure 49), unthread the handwheel, loosen the inner set of set screws, then remove the mounting hub.

Handwheel |

| Outboard |

|

| Mounting Hub |

|

| |

|

|

|

Set Screws

Figure 49. Outboard mounting hub.

11.Loosen the set screws on the outboard mount- ing hub adapter (see Figure 50). Unthread the mounting hub adapter using a spanner wrench with a 5mm pin, or by placing a 5mm diameter metal rod long enough to be used as a lever into the spanner nut hole.

Mounting |

|

|

| Spanner | |

Hub |

| |

| Nut | |

Adapter |

| |

|

| |

|

| |

|

|

|