Installing Faceplate/

Handwheel

Always disconnect the lathe from power before using the spindle lock feature. Never resume turning operations without making sure that the spindle lock is disengaged and the spindle turns freely by hand. Otherwise personal injury or property damage could result.

The faceplate can be mounted on the outboard side of the lathe for turning workpieces larger than 20" in diameter. In this case, the handwheel is mounted on the inboard side.

To mount a workpiece to the faceplate, refer to Faceplate Turning on Page 30.

Tools Needed | Qty |

............................... 1 |

Installing Faceplate or Handwheel

1.DISCONNECT LATHE FROM POWER!

2.Pull the spindle lock lever out, then rotate it from the twelve o'clock unlocked posi- tion to the six o'clock locked position (see

Figure 19).

Spindle

Lock

Lever

Figure 19. Using the spindle lock lever.

3.Rotate the spindle by hand until the lock pin engages and keeps the spindle from rotat- ing.

4.Apply a thin coat of light machine oil on the spindle threads, then thread the faceplate or handwheel onto the spindle until it is snug.

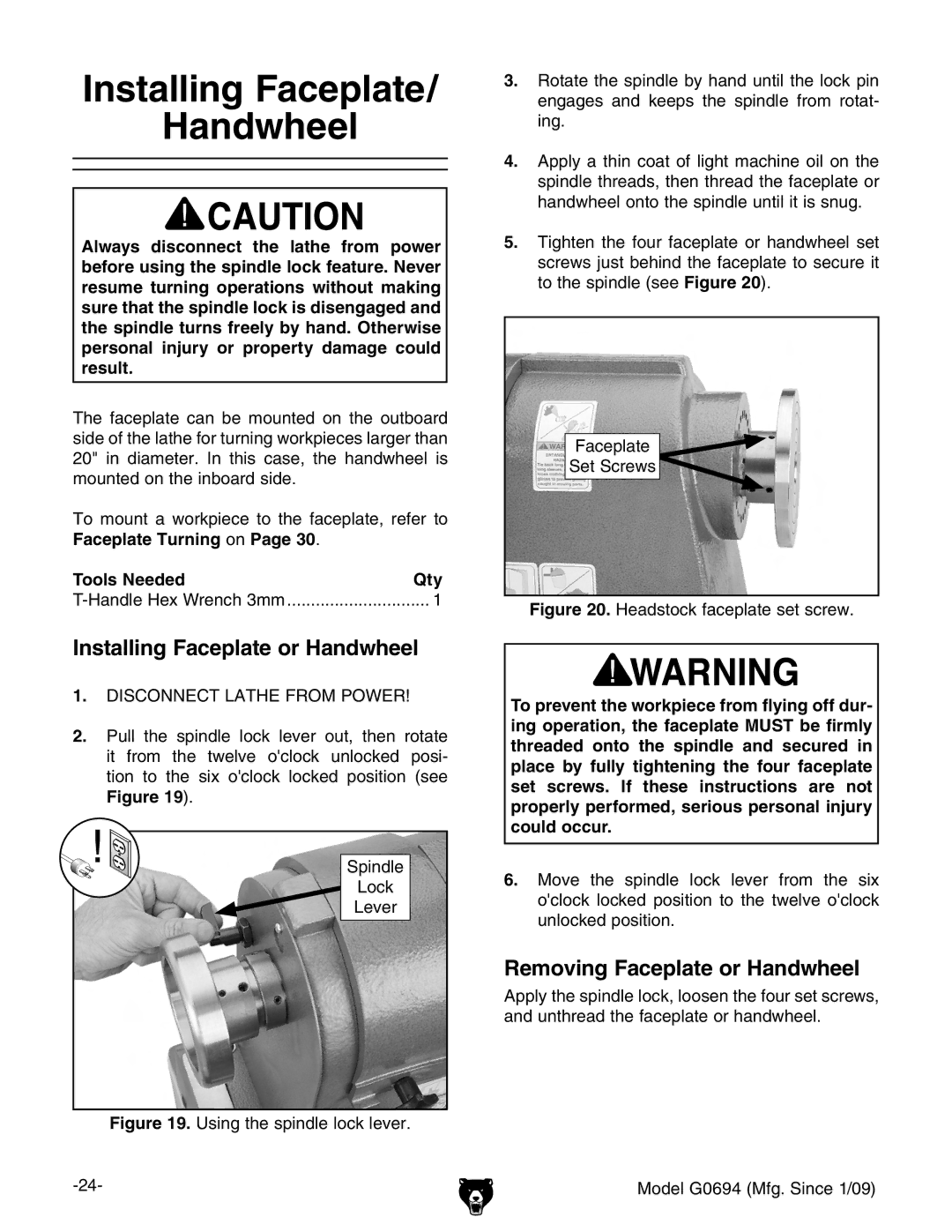

5.Tighten the four faceplate or handwheel set screws just behind the faceplate to secure it to the spindle (see Figure 20).

Faceplate

Set Screws

Figure 20. Headstock faceplate set screw.

To prevent the workpiece from flying off dur- ing operation, the faceplate MUST be firmly threaded onto the spindle and secured in place by fully tightening the four faceplate set screws. If these instructions are not properly performed, serious personal injury could occur.

6.Move the spindle lock lever from the six o'clock locked position to the twelve o'clock unlocked position.

Removing Faceplate or Handwheel

Apply the spindle lock, loosen the four set screws, and unthread the faceplate or handwheel.

Model G0694 (Mfg. Since 1/09)