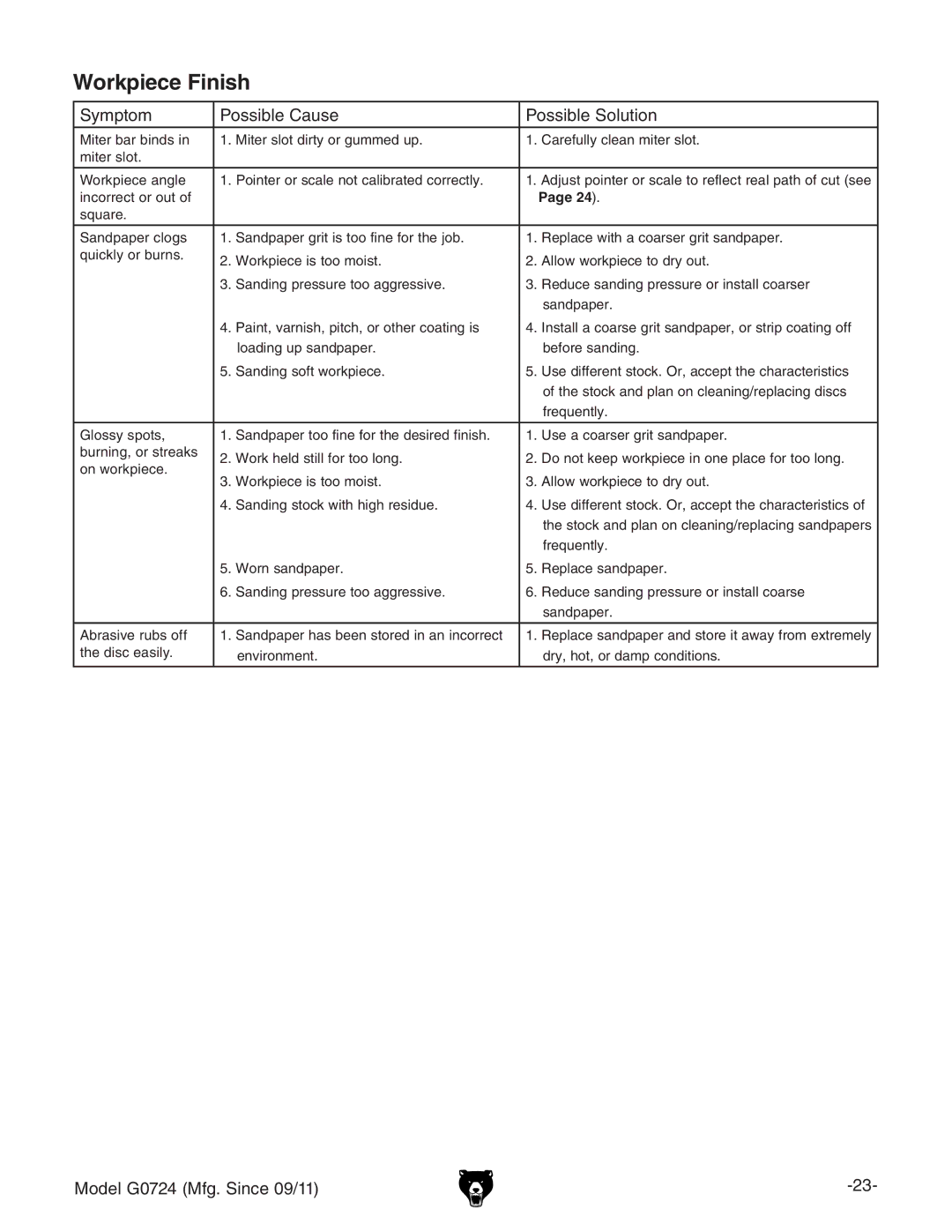

Workpiece Finish

Symptom | Possible Cause | Possible Solution | |||

Miter bar binds in | 1. Miter slot dirty or gummed up. | 1. | Carefully clean miter slot. | ||

miter slot. |

|

|

|

| |

|

|

| |||

Workpiece angle | 1. Pointer or scale not calibrated correctly. | 1. Adjust pointer or scale to reflect real path of cut (see | |||

incorrect or out of |

|

|

| Page 24). | |

square. |

|

|

|

| |

|

|

|

| ||

Sandpaper clogs | 1. Sandpaper grit is too fine for the job. | 1. | Replace with a coarser grit sandpaper. | ||

quickly or burns. | 2. | Workpiece is too moist. | 2. | Allow workpiece to dry out. | |

| |||||

| 3. | Sanding pressure too aggressive. | 3. | Reduce sanding pressure or install coarser | |

|

|

|

| sandpaper. | |

| 4. | Paint, varnish, pitch, or other coating is | 4. | Install a coarse grit sandpaper, or strip coating off | |

|

| loading up sandpaper. |

| before sanding. | |

| 5. | Sanding soft workpiece. | 5. | Use different stock. Or, accept the characteristics | |

|

|

|

| of the stock and plan on cleaning/replacing discs | |

|

|

|

| frequently. | |

|

|

|

| ||

Glossy spots, | 1. Sandpaper too fine for the desired finish. | 1. | Use a coarser grit sandpaper. | ||

burning, or streaks | 2. | Work held still for too long. | 2. | Do not keep workpiece in one place for too long. | |

on workpiece. | |||||

3. | Workpiece is too moist. | 3. | Allow workpiece to dry out. | ||

| |||||

| 4. | Sanding stock with high residue. | 4. | Use different stock. Or, accept the characteristics of | |

|

|

|

| the stock and plan on cleaning/replacing sandpapers | |

|

|

|

| frequently. | |

| 5. | Worn sandpaper. | 5. | Replace sandpaper. | |

| 6. | Sanding pressure too aggressive. | 6. | Reduce sanding pressure or install coarse | |

|

|

|

| sandpaper. | |

|

|

|

| ||

Abrasive rubs off | 1. Sandpaper has been stored in an incorrect | 1. | Replace sandpaper and store it away from extremely | ||

the disc easily. |

| environment. |

| dry, hot, or damp conditions. | |

|

|

|

|

| |

Model G0724 (Mfg. Since 09/11) |