Replacing

Sandpaper

The Model G0724 sander accepts 12" diameter

The sandpaper sticks to the surface of the disc, using the pressure sensitive adhesive (PSA) backing. The sandpaper can be replaced without removing either the table or the lower disc guard (see Accessories on Page 19).

To replace the sanding disc:

1.DISCONNECT MACHINE FROM POWER!

2.Peel off the old sandpaper, clean the disc surface with mineral spirits, and wipe it dry.

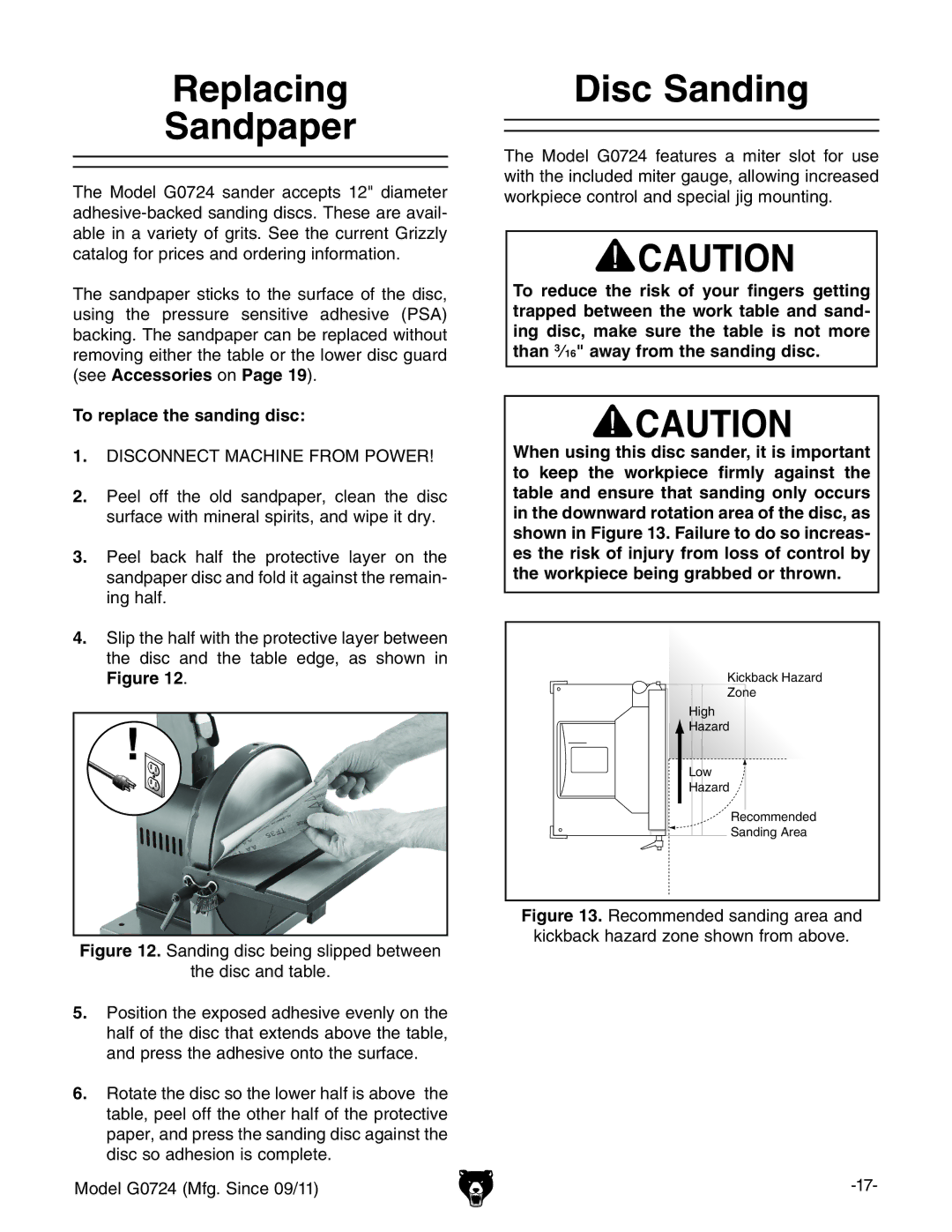

3.Peel back half the protective layer on the sandpaper disc and fold it against the remain- ing half.

4.Slip the half with the protective layer between the disc and the table edge, as shown in

Figure 12.

Figure 12. Sanding disc being slipped between

the disc and table.

5.Position the exposed adhesive evenly on the half of the disc that extends above the table, and press the adhesive onto the surface.

6.Rotate the disc so the lower half is above the table, peel off the other half of the protective paper, and press the sanding disc against the disc so adhesion is complete.

Model G0724 (Mfg. Since 09/11)

Disc Sanding

The Model G0724 features a miter slot for use with the included miter gauge, allowing increased workpiece control and special jig mounting.

To reduce the risk of your fingers getting trapped between the work table and sand- ing disc, make sure the table is not more than 3⁄16" away from the sanding disc.

When using this disc sander, it is important to keep the workpiece firmly against the table and ensure that sanding only occurs in the downward rotation area of the disc, as shown in Figure 13. Failure to do so increas- es the risk of injury from loss of control by the workpiece being grabbed or thrown.

Kickback Hazard

Zone

High

![]() Hazard

Hazard

Low

Hazard

Recommended

Sanding Area