SECTION 4: OPERATIONS

Operation Safety

Damage to your eyes, lungs, and ears could result from using this machine without proper protective gear. Always wear safety glasses, a respirator, and hearing protection when operating this machine.

Loose hair and cloth-

ing could get caught in

![]() machinery and cause seri-

machinery and cause seri-

ous personal injury. Keep

loose clothing and long

hair away from moving machinery.

NOTICE

If you have never used this type of machine or equipment before, WE STRONGLY REC- OMMEND that you read books, trade maga- zines, or get formal training before begin- ning any projects. Regardless of the con- tent in this section, Grizzly Industrial will not be held liable for accidents caused by lack of training.

Installing/Removing

Tooling

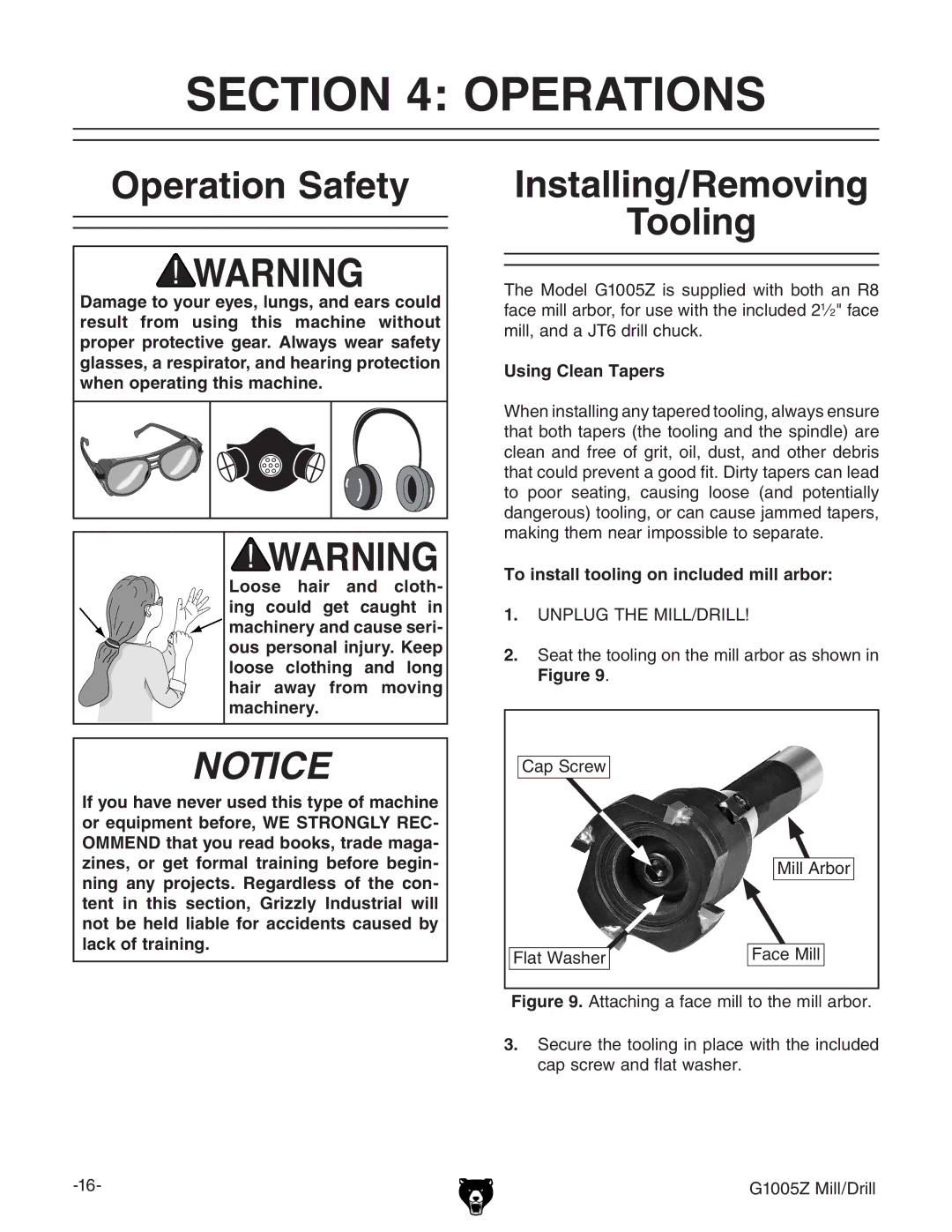

The Model G1005Z is supplied with both an R8 face mill arbor, for use with the included 21⁄2" face mill, and a JT6 drill chuck.

Using Clean Tapers

When installing any tapered tooling, always ensure that both tapers (the tooling and the spindle) are clean and free of grit, oil, dust, and other debris that could prevent a good fit. Dirty tapers can lead to poor seating, causing loose (and potentially dangerous) tooling, or can cause jammed tapers, making them near impossible to separate.

To install tooling on included mill arbor:

1.UNPLUG THE MILL/DRILL!

2.Seat the tooling on the mill arbor as shown in Figure 9.

Cap Screw

Mill Arbor

Flat Washer | Face Mill |