Depth Stop |

| Feed Shaft Spring |

Calibration |

| Tension |

|

|

|

|

|

|

The Model G1005Z comes fitted with a depth stop to use when drilling multiple holes at the same depth. The scale on this depth stop can be calibrated if it ever becomes incorrect.

To calibrate the depth stop:

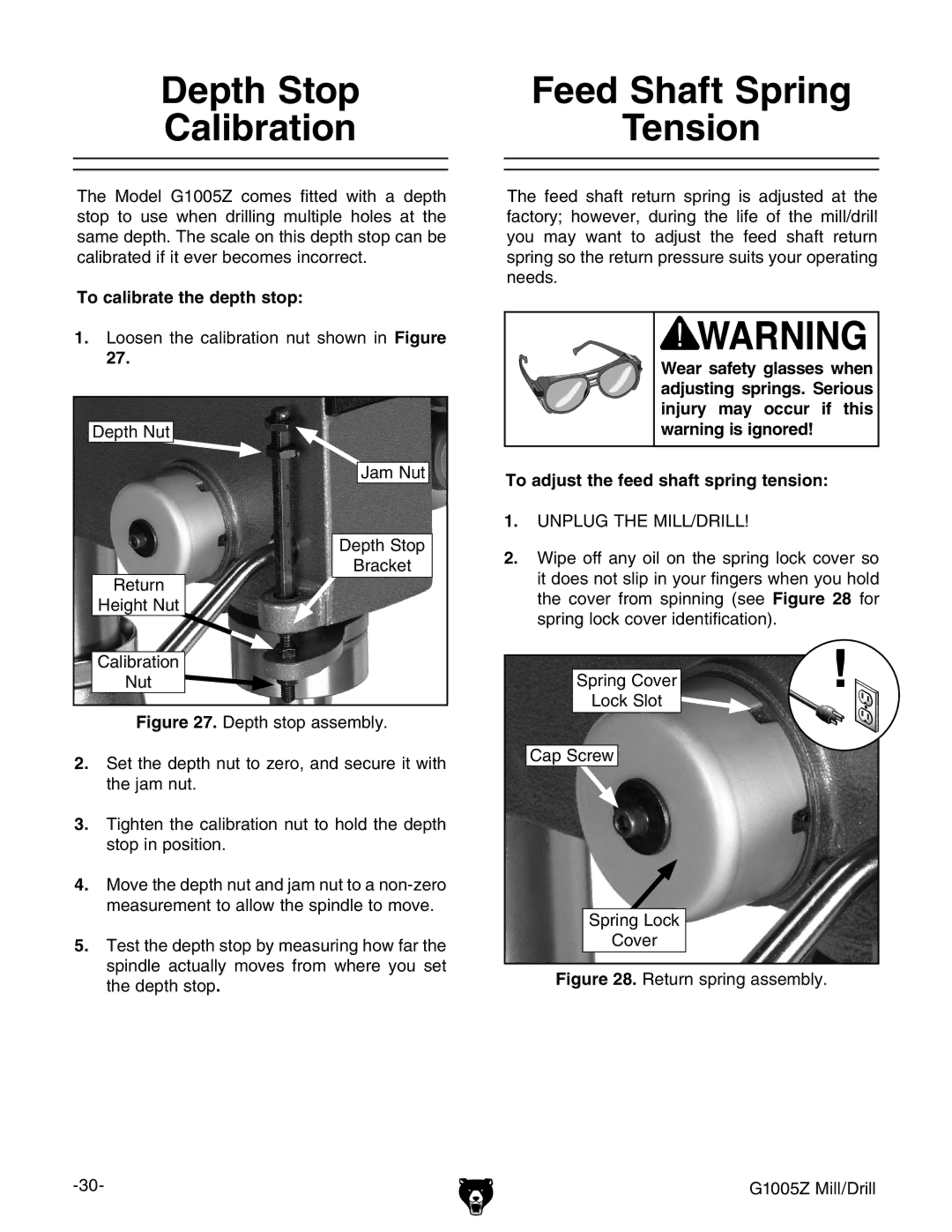

1.Loosen the calibration nut shown in Figure 27.

Depth Nut![]() Jam Nut

Jam Nut

Depth Stop

Bracket

Return

Height Nut

Calibration

Nut

Figure 27. Depth stop assembly.

2.Set the depth nut to zero, and secure it with the jam nut.

3.Tighten the calibration nut to hold the depth stop in position.

4.Move the depth nut and jam nut to a non-zero measurement to allow the spindle to move.

5.Test the depth stop by measuring how far the spindle actually moves from where you set

the depth stop.

The feed shaft return spring is adjusted at the factory; however, during the life of the mill/drill you may want to adjust the feed shaft return spring so the return pressure suits your operating needs.

Wear safety glasses when adjusting springs. Serious injury may occur if this warning is ignored!

To adjust the feed shaft spring tension:

1.UNPLUG THE MILL/DRILL!

2.Wipe off any oil on the spring lock cover so it does not slip in your fingers when you hold the cover from spinning (see Figure 28 for spring lock cover identification).

Spring Cover |

Lock Slot |

Cap Screw |

Spring Lock |

Cover |

Figure 28. Return spring assembly.

G1005Z Mill/Drill |