SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Loose mounting bolts.

•Worn or damaged wires.

•Any other unsafe condition.

•Mill/drill is completely powered down at the end of use.

•Excess cutting fluids and chips have been removed and unpainted surfaces are dry and protected.

Weekly Maintenance:

•Clean/grease all dovetail ways.

•Mill/drill is clean and lubricated.

Unpainted Cast Iron

Protect the unpainted cast iron surfaces on the table by wiping the table clean after every use— this ensures moisture does not remain on bare metal surfaces.

Keep tables

Lubrication

Since all bearings are shielded and permanently lubricated, simply leave them alone until they need to be replaced. DO NOT lubricate them.

Keep quill, spindle, column, and table top well lubricated to prevent rust.

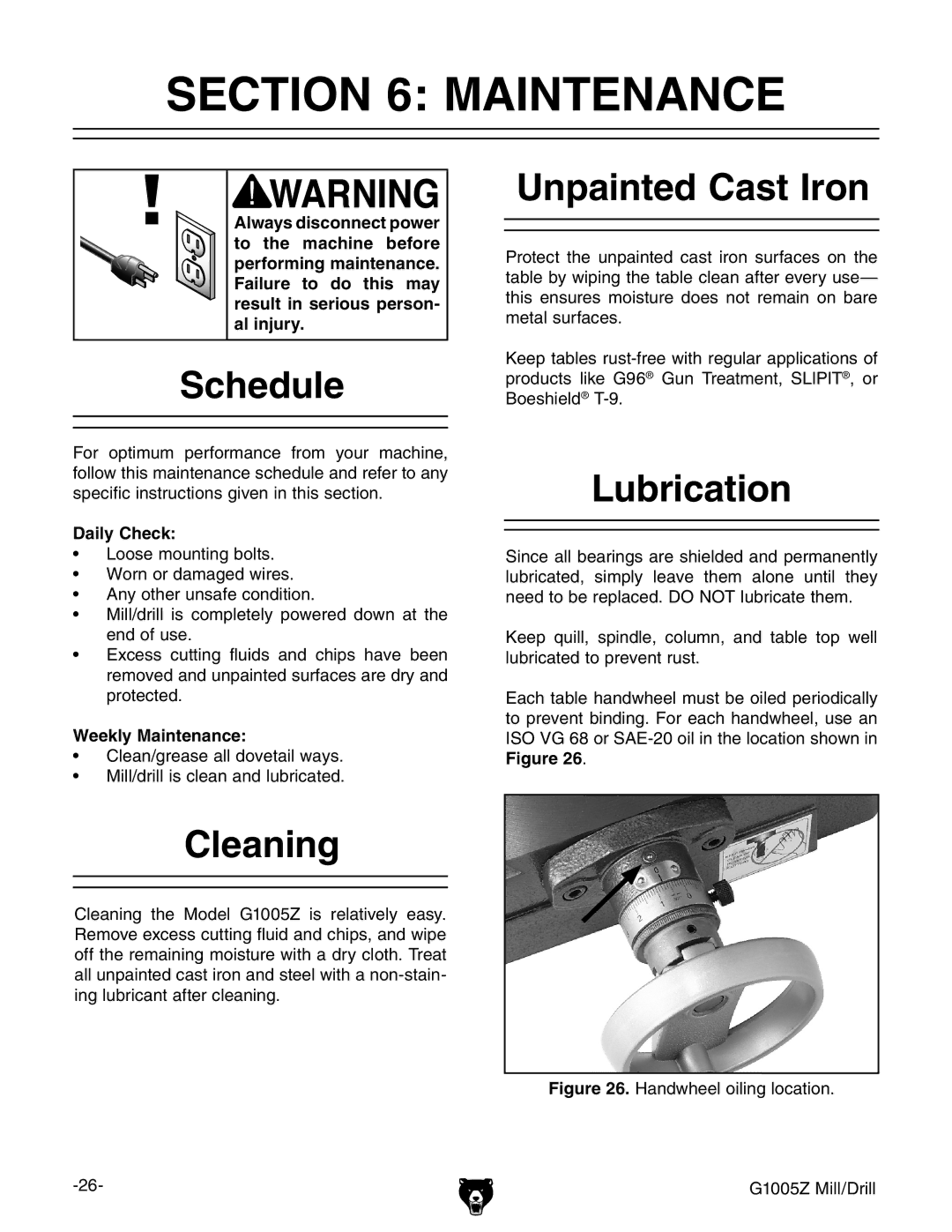

Each table handwheel must be oiled periodically to prevent binding. For each handwheel, use an ISO VG 68 or

Cleaning

Cleaning the Model G1005Z is relatively easy. Remove excess cutting fluid and chips, and wipe off the remaining moisture with a dry cloth. Treat all unpainted cast iron and steel with a