Saw Pressure

The pressure or force which the saw exerts when pushing through the workpiece is the result of the weight of the bow assembly counterbalanced by the amount of spring tension applied through the large coil spring on the back of the machine base. This should be set so there is a moderate amount of pressure. Harder or softer materials may require adjusting the head pressure for spe- cific operations. See Adjusting Feed Rate in the Operations Section.

Spring adjustment is performed in the following sequence:

1.Raise saw bow to the open position, with the bow at the top of its travel.

2.Open the hydraulic feed rate valve all the way by turning it counterclockwise.

3.The saw bow should come down at a slow steady rate. You should be able to stop its travel with a light upward force from one or two fingers.

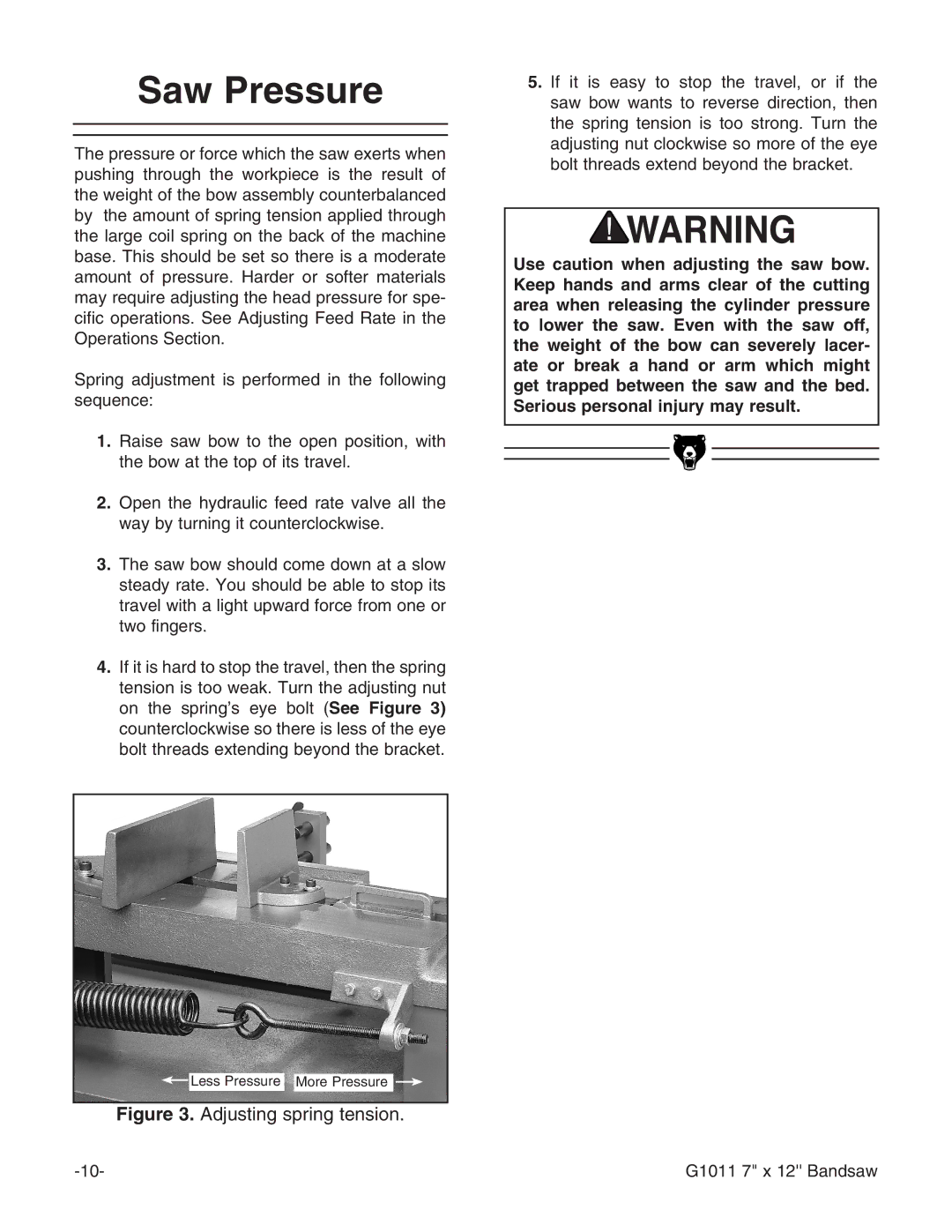

4.If it is hard to stop the travel, then the spring tension is too weak. Turn the adjusting nut on the spring’s eye bolt (See Figure 3) counterclockwise so there is less of the eye bolt threads extending beyond the bracket.

5.If it is easy to stop the travel, or if the saw bow wants to reverse direction, then the spring tension is too strong. Turn the adjusting nut clockwise so more of the eye bolt threads extend beyond the bracket.

Use caution when adjusting the saw bow. Keep hands and arms clear of the cutting area when releasing the cylinder pressure to lower the saw. Even with the saw off, the weight of the bow can severely lacer- ate or break a hand or arm which might get trapped between the saw and the bed. Serious personal injury may result.

![]() Less Pressure More Pressure

Less Pressure More Pressure

Figure 3. Adjusting spring tension.

G1011 7" x 12'' Bandsaw |