Adjusting Feed Rate |

| Coolant |

|

|

|

|

|

|

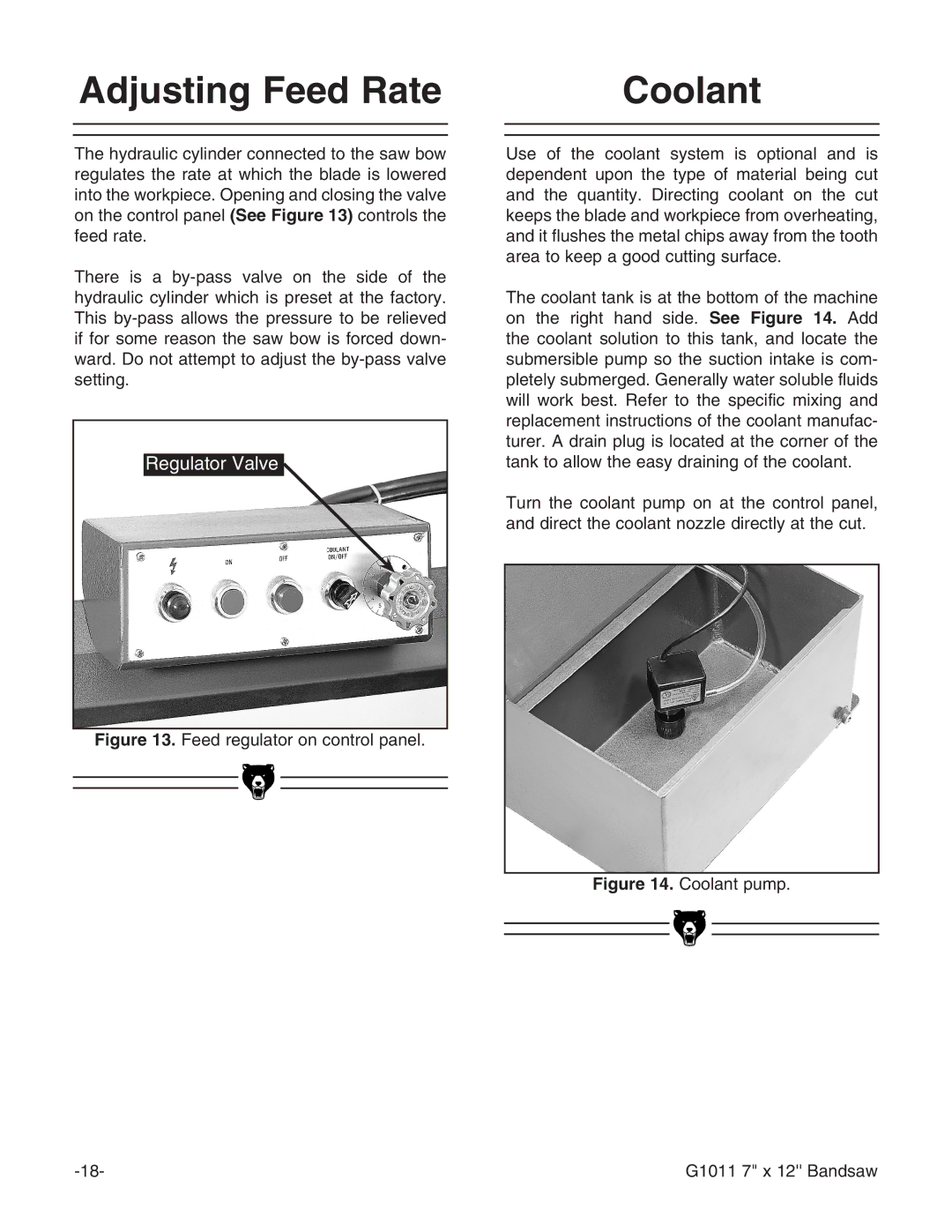

The hydraulic cylinder connected to the saw bow regulates the rate at which the blade is lowered into the workpiece. Opening and closing the valve on the control panel (See Figure 13) controls the feed rate.

There is a

Regulator Valve

Figure 13. Feed regulator on control panel.

Use of the coolant system is optional and is dependent upon the type of material being cut and the quantity. Directing coolant on the cut keeps the blade and workpiece from overheating, and it flushes the metal chips away from the tooth area to keep a good cutting surface.

The coolant tank is at the bottom of the machine on the right hand side. See Figure 14. Add the coolant solution to this tank, and locate the submersible pump so the suction intake is com- pletely submerged. Generally water soluble fluids will work best. Refer to the specific mixing and replacement instructions of the coolant manufac- turer. A drain plug is located at the corner of the tank to allow the easy draining of the coolant.

Turn the coolant pump on at the control panel, and direct the coolant nozzle directly at the cut.

Figure 14. Coolant pump.

G1011 7" x 12'' Bandsaw |