Blade Selection

A bandsaw blade is a ribbon of steel subjected to tremendous strain. Be sure you use qual- ity blades for the various types of cutting opera- tions. The Grizzly G1011Z bandsaw accepts 1'' x 101" blades. Bandsaw blades can be purchased welded, set, and sharpened

There are several key factors to consider in choosing a blade:

Tooth Pitch - The number of teeth per inch (TPI) on the blade, also known as tooth pitch. Select a pitch which will assure that at least three teeth are contacting the workpiece while cutting. This helps to dis- tribute the cutting forces and avoids tooth breakage.

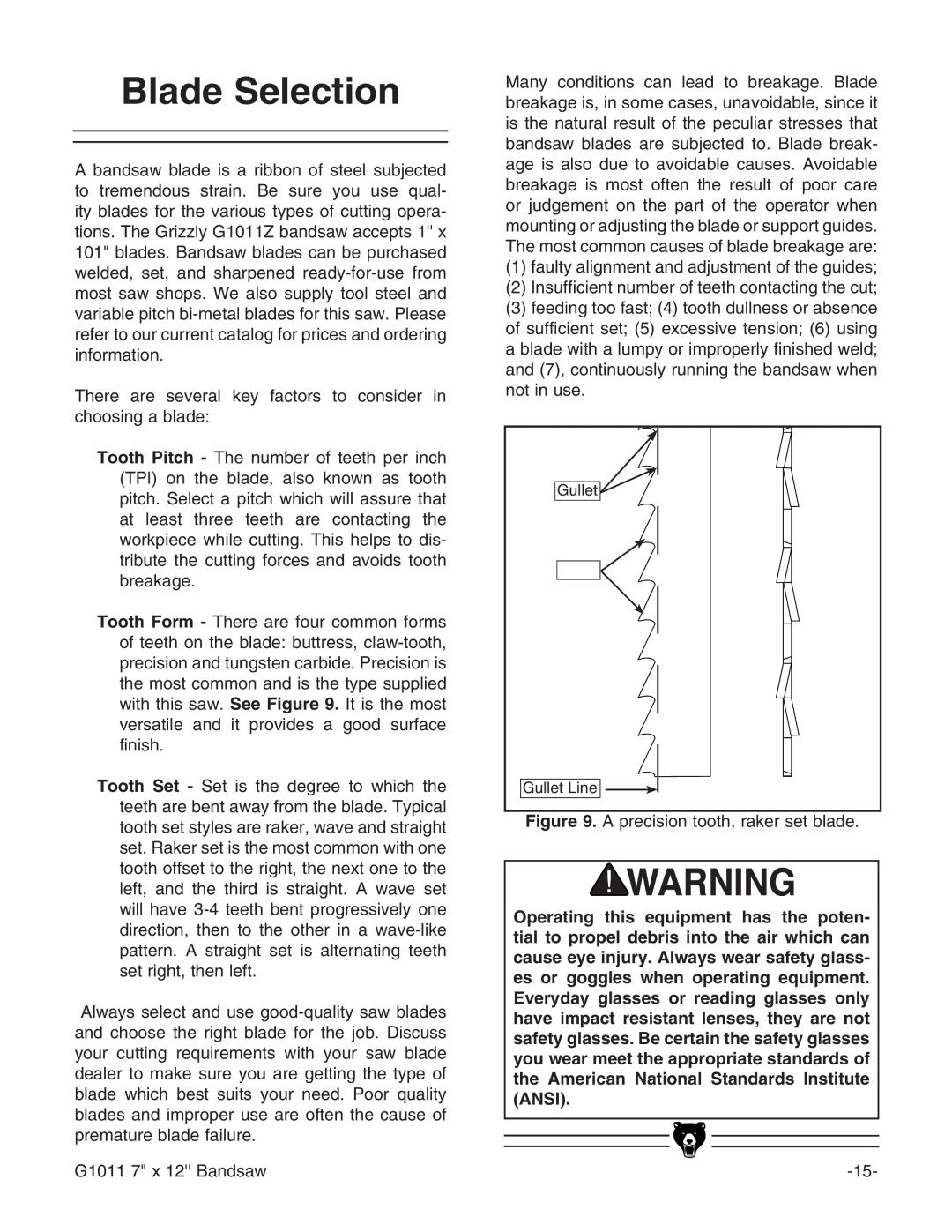

Tooth Form - There are four common forms of teeth on the blade: buttress,

Tooth Set - Set is the degree to which the teeth are bent away from the blade. Typical tooth set styles are raker, wave and straight set. Raker set is the most common with one tooth offset to the right, the next one to the left, and the third is straight. A wave set will have

Always select and use

G1011 7" x 12'' Bandsaw

Many conditions can lead to breakage. Blade breakage is, in some cases, unavoidable, since it is the natural result of the peculiar stresses that bandsaw blades are subjected to. Blade break- age is also due to avoidable causes. Avoidable breakage is most often the result of poor care or judgement on the part of the operator when mounting or adjusting the blade or support guides. The most common causes of blade breakage are:

(1)faulty alignment and adjustment of the guides;

(2)Insufficient number of teeth contacting the cut;

(3)feeding too fast; (4) tooth dullness or absence of sufficient set; (5) excessive tension; (6) using a blade with a lumpy or improperly finished weld; and (7), continuously running the bandsaw when not in use.

Gullet ![]()

Gullet Line ![]()

Figure 9. A precision tooth, raker set blade.

Operating this equipment has the poten- tial to propel debris into the air which can cause eye injury. Always wear safety glass- es or goggles when operating equipment. Everyday glasses or reading glasses only have impact resistant lenses, they are not safety glasses. Be certain the safety glasses you wear meet the appropriate standards of the American National Standards Institute (ANSI).