Pulley alignment and belt tension should now be adjusted simultaneously.

1.Situate the motor so the

Motor Mount

Bolts

Figure 9A. Motor mount bolt locations.

If the pulleys will not align by moving the motor only, loosen the bandsaw mounting bolts and position the bandsaw so the step pulley aligns with the motor pulley. Leave the motor mount bolts loose.

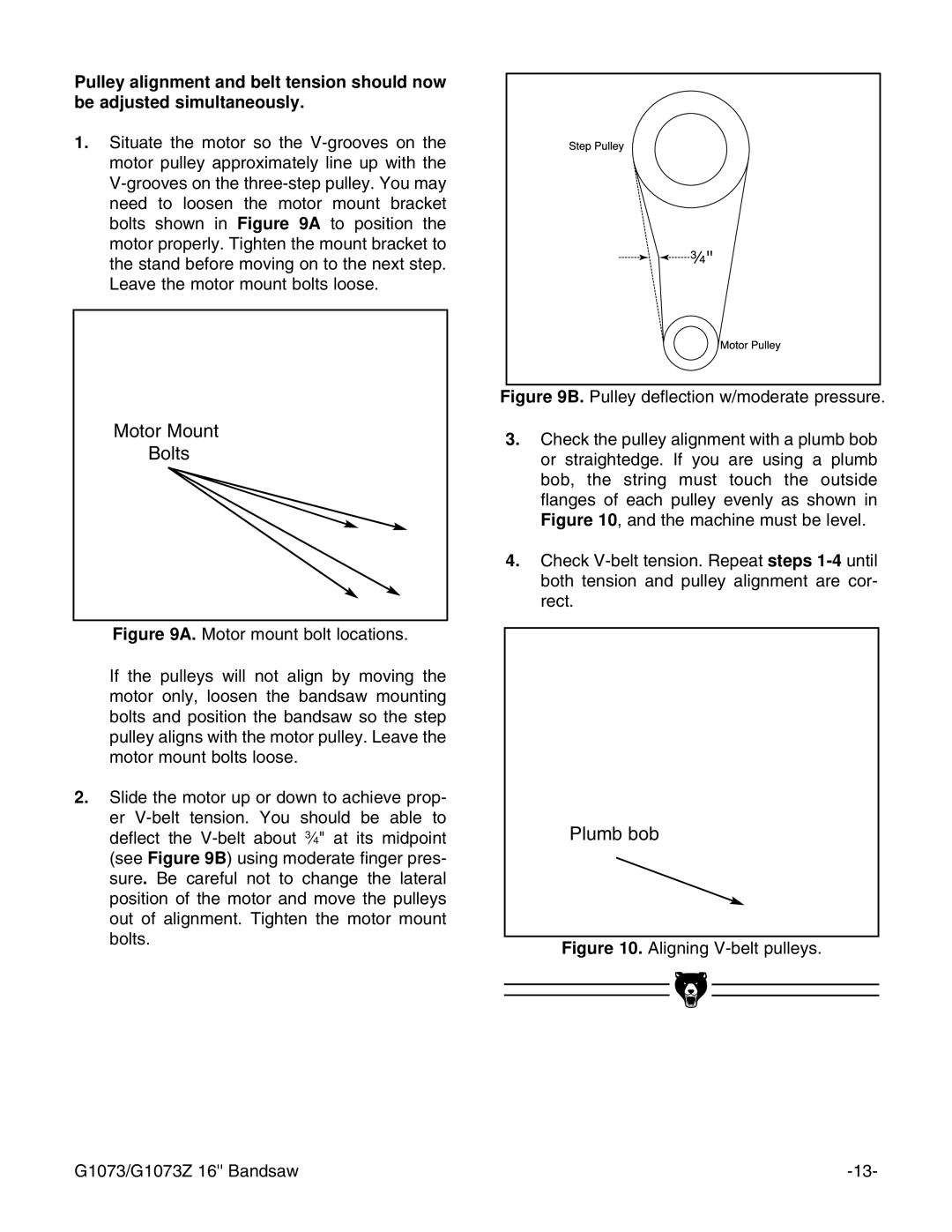

2.Slide the motor up or down to achieve prop- er V-belt tension. You should be able to deflect the V-belt about 3Ú4" at its midpoint (see Figure 9B) using moderate finger pres- sure. Be careful not to change the lateral position of the motor and move the pulleys out of alignment. Tighten the motor mount bolts.

Figure 9B. Pulley deflection w/moderate pressure.

3.Check the pulley alignment with a plumb bob or straightedge. If you are using a plumb bob, the string must touch the outside flanges of each pulley evenly as shown in Figure 10, and the machine must be level.

4.Check V-belt tension. Repeat steps 1-4 until both tension and pulley alignment are cor- rect.

Plumb bob

Figure 10. Aligning V-belt pulleys.

|

|

|

|

|

|

|

|

|

|

|

|

G1073/G1073Z 16'' Bandsaw | |||