SECTION 5: ADJUSTMENTS

Keep loose clothing rolled up and out of the way of machinery and keep hair pulled back.

Disconnect power to the machine when perform- ing any adjustments or maintenance. Failure to do this may result in seri- ous personal injury.

Wear safety glasses dur- ing the entire adjustment process. Failure to com- ply may result in serious personal injury.

Pulleys & V-Belt

Improper pulley alignment sharply reduces the effectiveness of power transmission and belt life expectancy. To align the pulleys:

1.Remove the motor cover from the back of the shaper cabinet to expose the motor and pulleys.

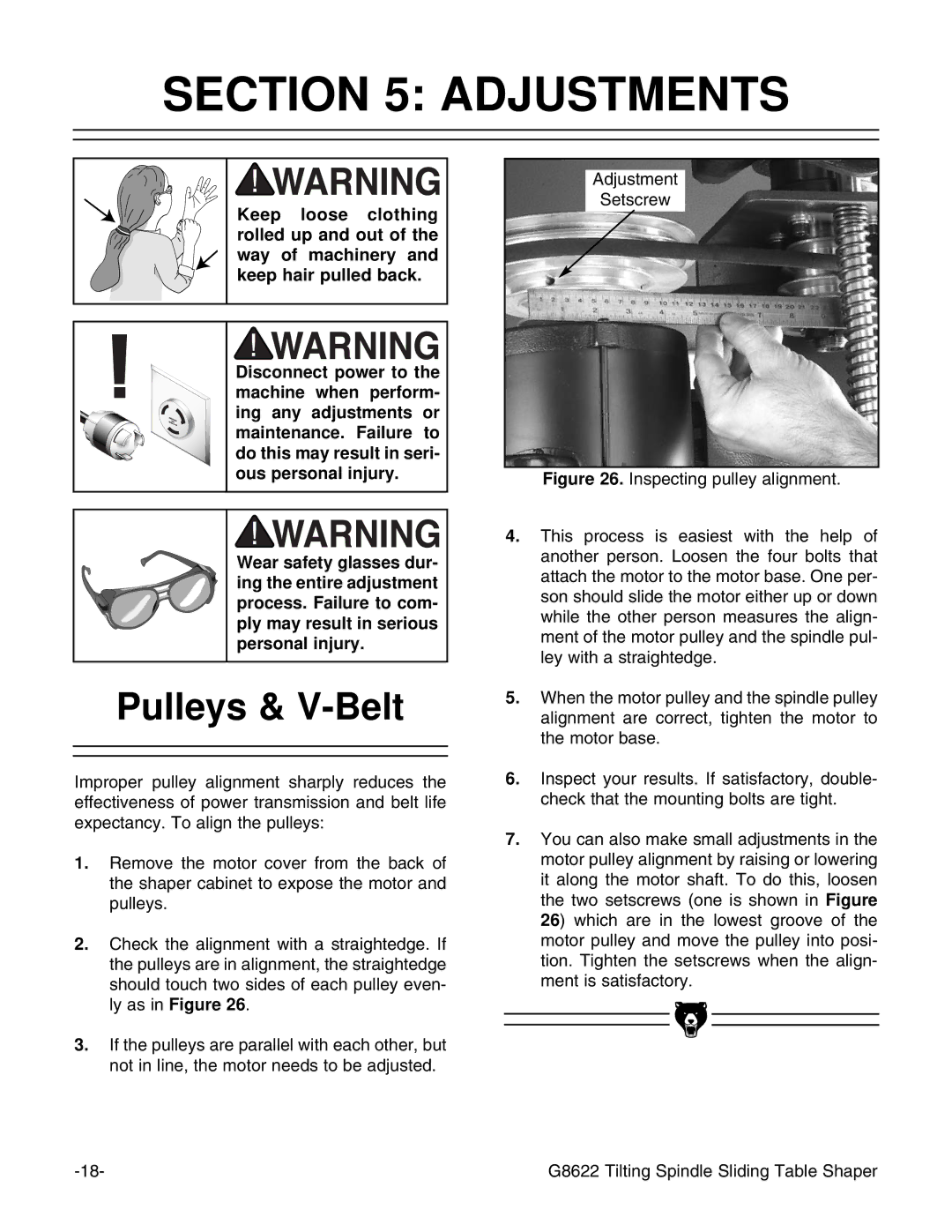

2.Check the alignment with a straightedge. If the pulleys are in alignment, the straightedge should touch two sides of each pulley even- ly as in Figure 26.

3.If the pulleys are parallel with each other, but not in line, the motor needs to be adjusted.

Adjustment

Setscrew

Figure 26. Inspecting pulley alignment.

4.This process is easiest with the help of another person. Loosen the four bolts that attach the motor to the motor base. One per- son should slide the motor either up or down while the other person measures the align- ment of the motor pulley and the spindle pul- ley with a straightedge.

5.When the motor pulley and the spindle pulley alignment are correct, tighten the motor to the motor base.

6.Inspect your results. If satisfactory, double- check that the mounting bolts are tight.

7.You can also make small adjustments in the motor pulley alignment by raising or lowering it along the motor shaft. To do this, loosen the two setscrews (one is shown in Figure 26) which are in the lowest groove of the motor pulley and move the pulley into posi- tion. Tighten the setscrews when the align- ment is satisfactory.

G8622 Tilting Spindle Sliding Table Shaper |