4.Loosen the mounting screws on the fence faces and set the face ends to barely clear the cutter. This allows the maximum support possible for the workpiece while passing the cutter. Remember to tighten the wood facing before starting the shaper.

5.A test sample of the desired cut should be advanced about 8'' then stopped.

6.Once the shaper is turned off and the cutter has come to a complete stop, adjust the out- feed fence to support the new profiled edge.

See Figure 37.

Figure 37. Fence adjusted to support workpiece.

If the face of the workpiece will only be par- tially removed, observe the following steps:

1.Adjust the infeed fence to approximately the desired depth of cut. Lock the infeed fence in place.

2.Use a straightedge to adjust the outfeed fence to the same plane as the infeed. Lock the outfeed fence in place.

3.Set the right and left wood face ends so they barely clear the cutter. This allows the maxi- mum support possible for the workpiece while passing the cutter. Remember to tight- en down the wood facing before starting the shaper.

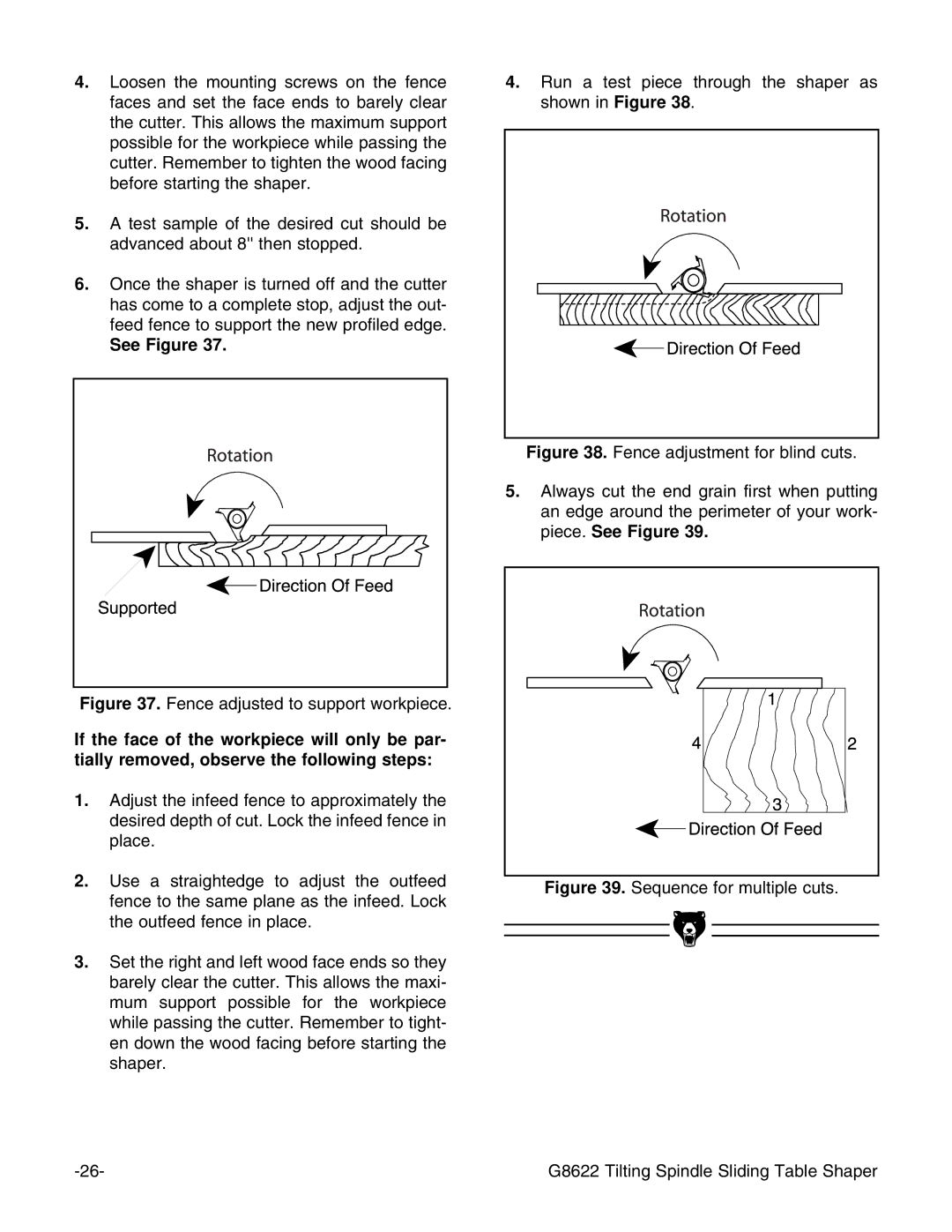

4.Run a test piece through the shaper as shown in Figure 38.

Figure 38. Fence adjustment for blind cuts.

5.Always cut the end grain first when putting an edge around the perimeter of your work- piece. See Figure 39.

Figure 39. Sequence for multiple cuts.

G8622 Tilting Spindle Sliding Table Shaper |