Troubleshooting

Machine Operations

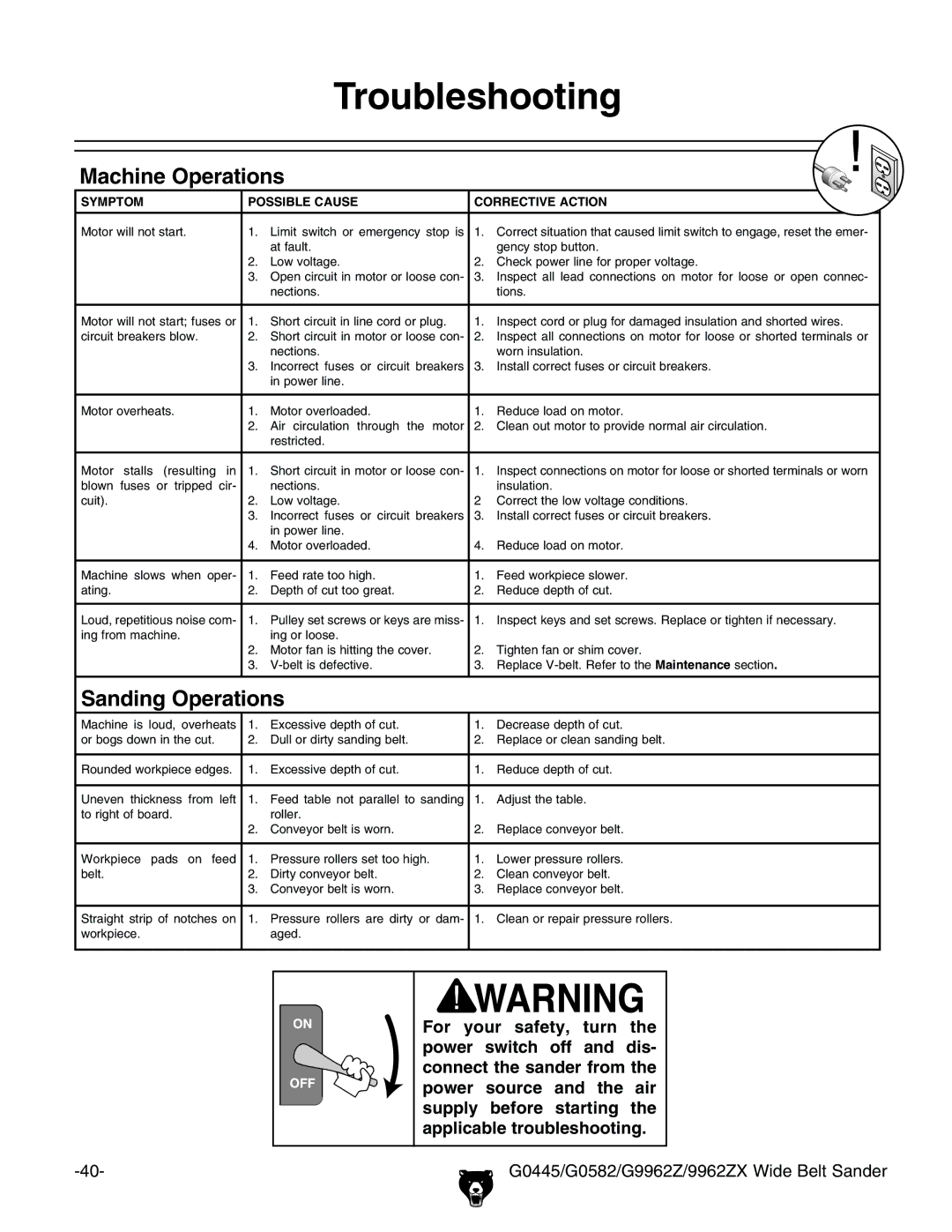

SYMPTOM |

|

| POSSIBLE CAUSE | CORRECTIVE ACTION | |||

|

|

|

|

|

|

| |

Motor will not start. |

|

| 1. | Limit switch or emergency stop is | 1. | Correct situation that caused limit switch to engage, reset the emer- | |

|

|

|

|

| at fault. |

| gency stop button. |

|

|

|

| 2. | Low voltage. | 2. | Check power line for proper voltage. |

|

|

|

| 3. | Open circuit in motor or loose con- | 3. | Inspect all lead connections on motor for loose or open connec- |

|

|

|

|

| nections. |

| tions. |

|

|

|

|

| |||

Motor will not start; fuses or | 1. | Short circuit in line cord or plug. | 1. | Inspect cord or plug for damaged insulation and shorted wires. | |||

circuit breakers blow. |

| 2. | Short circuit in motor or loose con- | 2. | Inspect all connections on motor for loose or shorted terminals or | ||

|

|

|

|

| nections. |

| worn insulation. |

|

|

|

| 3. | Incorrect fuses or circuit breakers | 3. | Install correct fuses or circuit breakers. |

|

|

|

|

| in power line. |

|

|

|

|

|

|

|

|

| |

Motor overheats. |

|

| 1. | Motor overloaded. | 1. | Reduce load on motor. | |

|

|

|

| 2. | Air circulation through the motor | 2. | Clean out motor to provide normal air circulation. |

|

|

|

|

| restricted. |

|

|

|

|

|

|

|

|

| |

Motor | stalls (resulting | in | 1. | Short circuit in motor or loose con- | 1. | Inspect connections on motor for loose or shorted terminals or worn | |

blown fuses or tripped cir- |

| nections. |

| insulation. | |||

cuit). |

|

|

| 2. | Low voltage. | 2 | Correct the low voltage conditions. |

|

|

|

| 3. | Incorrect fuses or circuit breakers | 3. | Install correct fuses or circuit breakers. |

|

|

|

|

| in power line. |

|

|

|

|

|

| 4. | Motor overloaded. | 4. | Reduce load on motor. |

|

|

|

|

| |||

Machine slows when oper- | 1. | Feed rate too high. | 1. | Feed workpiece slower. | |||

ating. |

|

|

| 2. | Depth of cut too great. | 2. | Reduce depth of cut. |

|

|

|

|

| |||

Loud, repetitious noise com- | 1. | Pulley set screws or keys are miss- | 1. | Inspect keys and set screws. Replace or tighten if necessary. | |||

ing from machine. |

|

|

| ing or loose. |

|

| |

|

|

|

| 2. | Motor fan is hitting the cover. | 2. | Tighten fan or shim cover. |

|

|

|

| 3. | 3. | Replace | |

|

|

|

| ||||

Sanding Operations |

|

| |||||

Machine is loud, overheats | 1. | Excessive depth of cut. | 1. | Decrease depth of cut. | |||

or bogs down in the cut. |

| 2. | Dull or dirty sanding belt. | 2. | Replace or clean sanding belt. | ||

|

|

|

|

| |||

Rounded workpiece edges. | 1. | Excessive depth of cut. | 1. | Reduce depth of cut. | |||

|

|

|

|

|

|

|

|

Uneven | thickness | from | left | 1. | Feed table not parallel to sanding | 1. | Adjust the table. |

to right of board. |

|

|

| roller. |

|

| |

|

|

|

| 2. | Conveyor belt is worn. | 2. | Replace conveyor belt. |

|

|

|

|

|

| ||

Workpiece pads | on feed | 1. | Pressure rollers set too high. | 1. | Lower pressure rollers. | ||

belt. |

|

|

| 2. | Dirty conveyor belt. | 2. | Clean conveyor belt. |

|

|

|

| 3. | Conveyor belt is worn. | 3. | Replace conveyor belt. |

|

|

|

|

| |||

Straight strip of notches on | 1. | Pressure rollers are dirty or dam- | 1. | Clean or repair pressure rollers. | |||

workpiece. |

|

|

| aged. |

|

| |

|

|

|

|

|

|

|

|

For your safety, turn the power switch off and dis- connect the sander from the power source and the air supply before starting the applicable troubleshooting.

G0445/G0582/G9962Z/9962ZX Wide Belt Sander |