Pressure Roller

Depth

Variables such as feed rate, depth of the cut, and type of sanding belt can play a big part in deter- mining the proper amount of downward pressure exerted by the rollers. Some experimentation may be necessary with pressure roller spring ten- sion to achieve the desired results. However, under no circumstances should the pressure roller depth be set even, or higher than, the sand- ing rollers or platen.

To adjust the pressure roller depth:

1.Unplug the sander!

2.Joint and plane a 6" W x 36"L piece of wood, then rip it down the middle. This will give you two boards that are nearly the exact same thickness.

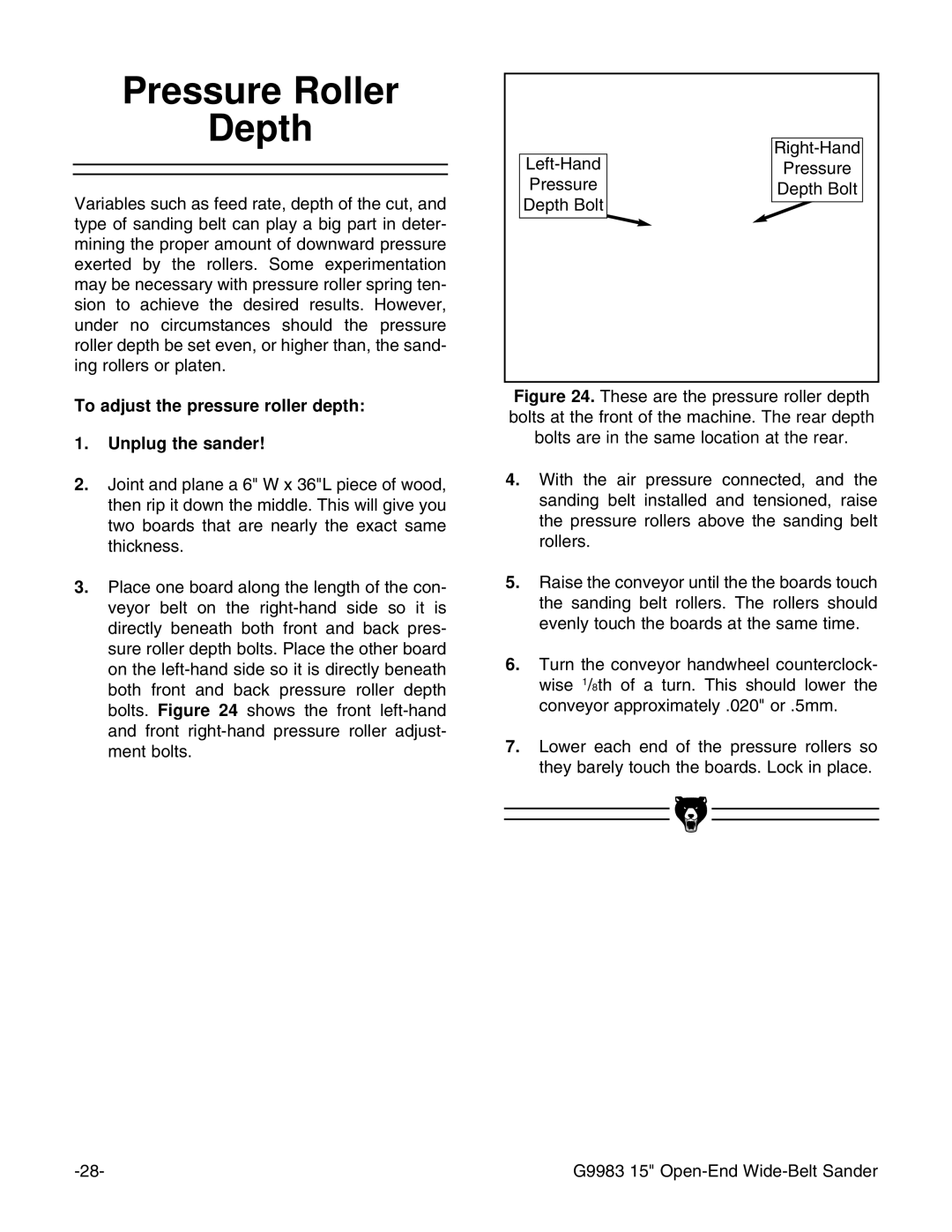

3.Place one board along the length of the con- veyor belt on the

|

| |

| Pressure | |

Pressure |

| Depth Bolt |

Depth Bolt |

|

|

|

|

Figure 24. These are the pressure roller depth bolts at the front of the machine. The rear depth bolts are in the same location at the rear.

4.With the air pressure connected, and the sanding belt installed and tensioned, raise the pressure rollers above the sanding belt rollers.

5.Raise the conveyor until the the boards touch the sanding belt rollers. The rollers should evenly touch the boards at the same time.

6.Turn the conveyor handwheel counterclock- wise 1/8th of a turn. This should lower the conveyor approximately .020" or .5mm.

7.Lower each end of the pressure rollers so they barely touch the boards. Lock in place.

G9983 15" |