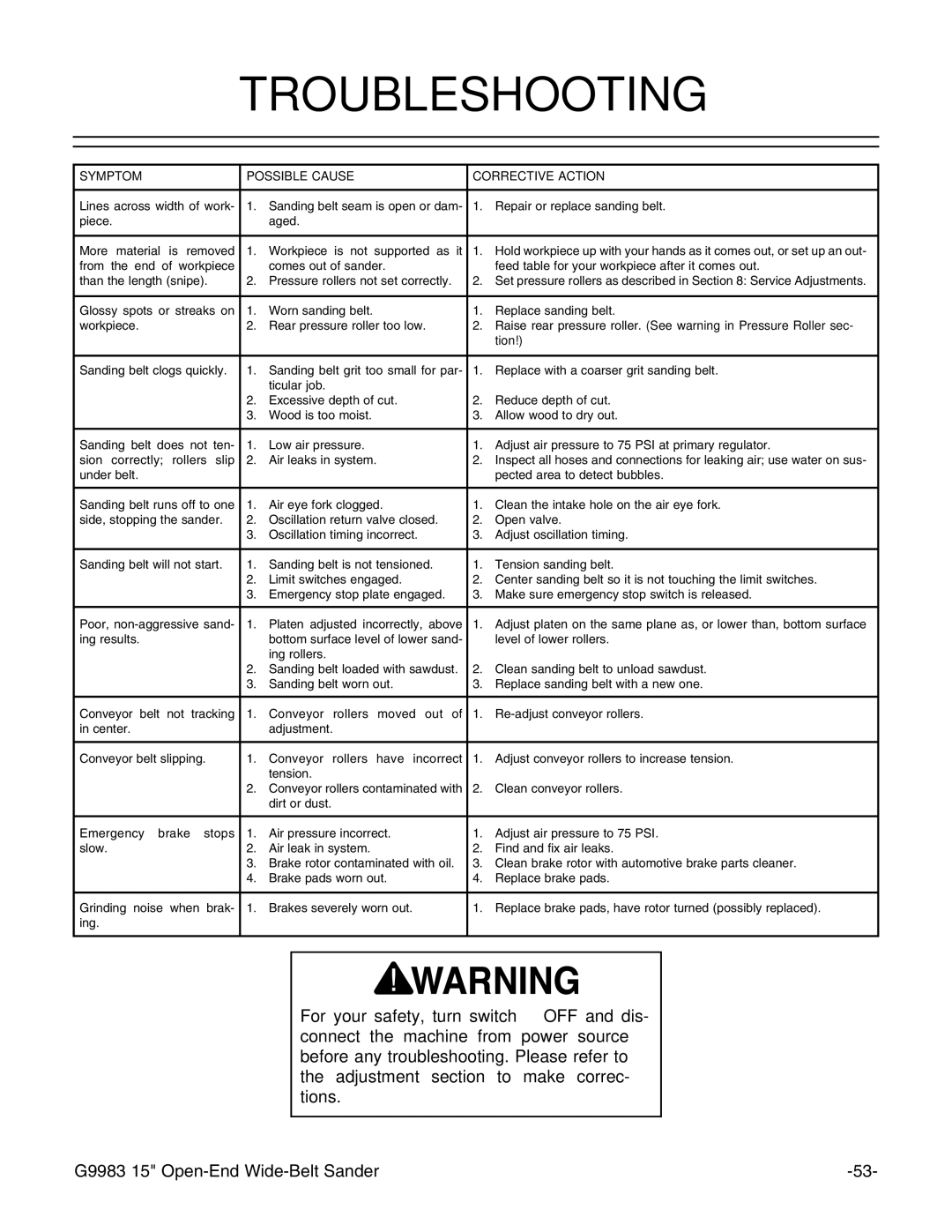

TROUBLESHOOTING

SYMPTOM |

| POSSIBLE CAUSE | CORRECTIVE ACTION | ||

|

|

|

|

| |

Lines across width of work- | 1. | Sanding belt seam is open or dam- | 1. | Repair or replace sanding belt. | |

piece. |

|

| aged. |

|

|

|

|

|

|

| |

More material is removed | 1. | Workpiece is not supported as it | 1. | Hold workpiece up with your hands as it comes out, or set up an out- | |

from the end of workpiece |

| comes out of sander. |

| feed table for your workpiece after it comes out. | |

than the length (snipe). | 2. | Pressure rollers not set correctly. | 2. | Set pressure rollers as described in Section 8: Service Adjustments. | |

|

|

|

|

| |

Glossy spots or streaks on | 1. | Worn sanding belt. | 1. | Replace sanding belt. | |

workpiece. |

| 2. | Rear pressure roller too low. | 2. | Raise rear pressure roller. (See warning in Pressure Roller sec- |

|

|

|

|

| tion!) |

|

|

|

|

| |

Sanding belt clogs quickly. | 1. | Sanding belt grit too small for par- | 1. | Replace with a coarser grit sanding belt. | |

|

|

| ticular job. |

|

|

|

| 2. | Excessive depth of cut. | 2. | Reduce depth of cut. |

|

| 3. | Wood is too moist. | 3. | Allow wood to dry out. |

|

|

|

|

| |

Sanding belt does not ten- | 1. | Low air pressure. | 1. | Adjust air pressure to 75 PSI at primary regulator. | |

sion correctly; rollers slip | 2. | Air leaks in system. | 2. | Inspect all hoses and connections for leaking air; use water on sus- | |

under belt. |

|

|

|

| pected area to detect bubbles. |

|

|

|

|

| |

Sanding belt runs off to one | 1. | Air eye fork clogged. | 1. | Clean the intake hole on the air eye fork. | |

side, stopping the sander. | 2. | Oscillation return valve closed. | 2. | Open valve. | |

|

| 3. | Oscillation timing incorrect. | 3. | Adjust oscillation timing. |

|

|

|

|

| |

Sanding belt will not start. | 1. | Sanding belt is not tensioned. | 1. | Tension sanding belt. | |

|

| 2. | Limit switches engaged. | 2. | Center sanding belt so it is not touching the limit switches. |

|

| 3. | Emergency stop plate engaged. | 3. | Make sure emergency stop switch is released. |

|

|

|

|

| |

Poor, | 1. | Platen adjusted incorrectly, above | 1. | Adjust platen on the same plane as, or lower than, bottom surface | |

ing results. |

|

| bottom surface level of lower sand- |

| level of lower rollers. |

|

|

| ing rollers. |

|

|

|

| 2. | Sanding belt loaded with sawdust. | 2. | Clean sanding belt to unload sawdust. |

|

| 3. | Sanding belt worn out. | 3. | Replace sanding belt with a new one. |

|

|

|

|

|

|

Conveyor belt not | tracking | 1. | Conveyor rollers moved out of | 1. | |

in center. |

|

| adjustment. |

|

|

|

|

|

|

| |

Conveyor belt slipping. | 1. | Conveyor rollers have incorrect | 1. | Adjust conveyor rollers to increase tension. | |

|

|

| tension. |

|

|

|

| 2. | Conveyor rollers contaminated with | 2. | Clean conveyor rollers. |

|

|

| dirt or dust. |

|

|

|

|

|

|

|

|

Emergency brake | stops | 1. | Air pressure incorrect. | 1. | Adjust air pressure to 75 PSI. |

slow. |

| 2. | Air leak in system. | 2. | Find and fix air leaks. |

|

| 3. | Brake rotor contaminated with oil. | 3. | Clean brake rotor with automotive brake parts cleaner. |

|

| 4. | Brake pads worn out. | 4. | Replace brake pads. |

|

|

|

|

| |

Grinding noise when brak- | 1. | Brakes severely worn out. | 1. | Replace brake pads, have rotor turned (possibly replaced). | |

ing. |

|

|

|

|

|

|

|

|

|

|

|

For your safety, turn switch OFF and dis- connect the machine from power source before any troubleshooting. Please refer to the adjustment section to make correc- tions.

G9983 15" |