Section 3 – Maintenance

4.Attach a tag to the engine indicating the viscosity and classification of the oil in the crankcase.

5.Remove the spark plug and pour two or three tablespoons of clean, fresh engine oil into the spark plug threaded openings. Reinstall and tighten the spark plug.

6.Remove the battery and store it in a cool, dry room on a wooden board. Never store the battery on any concrete or earthen floor.

7.Clean and wipe the entire generator.

3.12.2 RETURN TO SERVICE

To return the unit to service after storage, proceed as follows:

1.Check the tag on the engine for oil viscosity and classification. Verify that the correct recom- mended oil is used in the engine (see "Engine Oil Requirements"). If necessary, drain and refill with the proper oil.

2.Check the state of the battery. Fill all cells of unsealed batteries to the proper level with dis- tilled water. DO NOT USE TAP WATER IN THE BATTERY. Recharge the battery to 100 percent state of charge, or, if defective, replace the battery.

3.Clean and wipe the entire generator.

4.Reconnect the battery. Observe battery polarity. Damage may occur if the battery is connected incorrectly.

5.Turn OFF all electrical loads. Add fuel if neces- sary and then start the engine.

6.Allow the unit to run for several minutes to warm up.

7.Apply electrical loads to at least 50 percent of the unit’s rated wattage capacity.

8.When the engine is thoroughly warmed up, shut it down.

9.The generator is now ready for service.

3.13 ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, adjust the valve clearance in the engine.

When adjusting valve clearance, the engine should be at room temperature and the piston should be at Top Dead Center (TDC) of its compression stroke (both valves closed). Correct clearance is

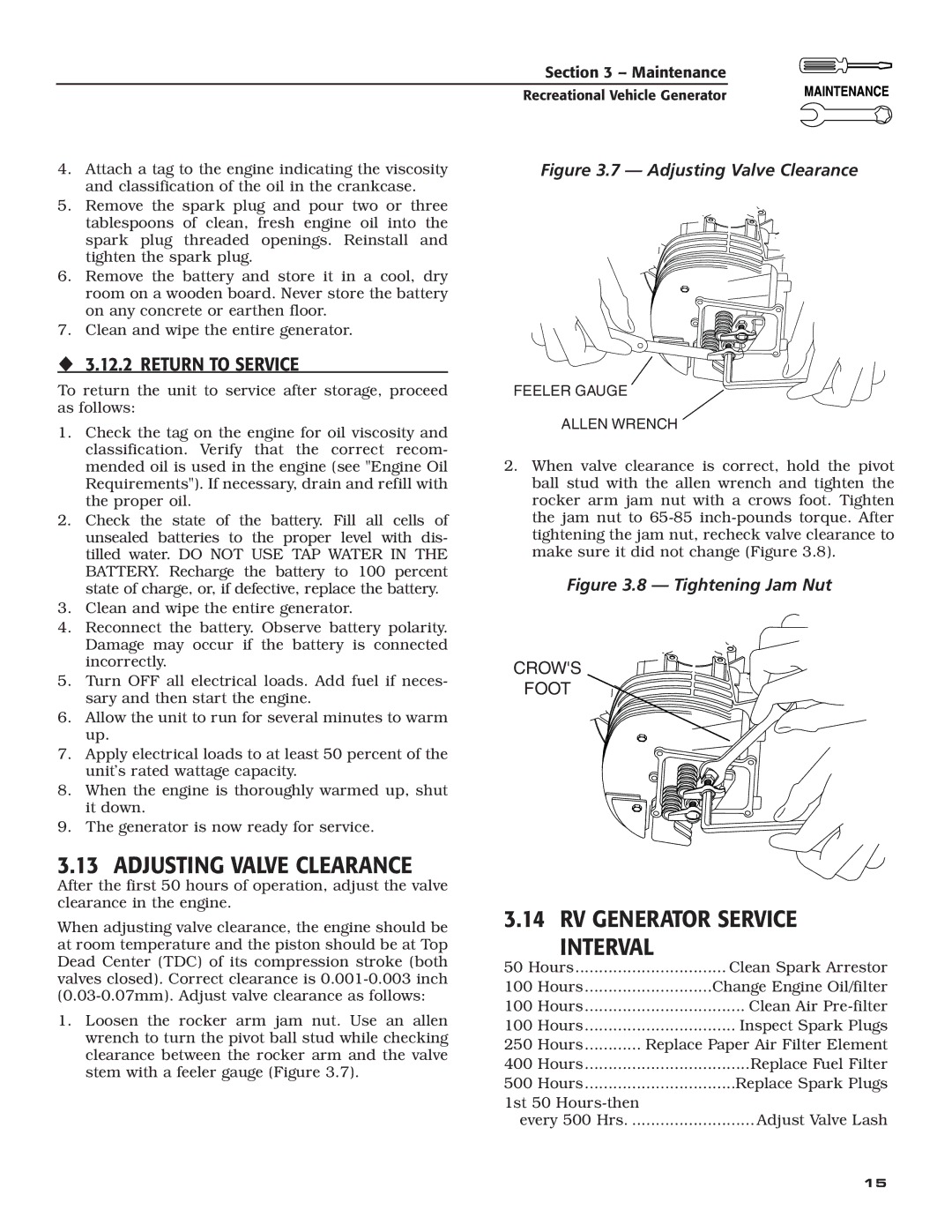

1.Loosen the rocker arm jam nut. Use an allen wrench to turn the pivot ball stud while checking clearance between the rocker arm and the valve stem with a feeler gauge (Figure 3.7).

Recreational Vehicle Generator

Figure 3.7 — Adjusting Valve Clearance

FEELER GAUGE

ALLEN WRENCH

2.When valve clearance is correct, hold the pivot ball stud with the allen wrench and tighten the rocker arm jam nut with a crows foot. Tighten the jam nut to

Figure 3.8 — Tightening Jam Nut

CROW'S

FOOT

3.14 RV GENERATOR SERVICE INTERVAL

50 Hours | Clean Spark Arrestor |

100 Hours | Change Engine Oil/filter |

100 Hours | Clean Air |

100 Hours | Inspect Spark Plugs |

250 Hours | Replace Paper Air Filter Element |

400 Hours | Replace Fuel Filter |

500 Hours | Replace Spark Plugs |

1st 50 |

|

every 500 Hrs | Adjust Valve Lash |

15