MECHANICAL ASSEMBLY

1 0 For security in shipping, the power transformer and the amplifier module have been fastened to the chassis. Remove the chassis cover, the inner front panel and the larger front plate, and set these aside. Be particularly careful in handling the amplifier module. to see that the leads of the upright compo- nents on the circuit boards are not stressed. This module accounts for more than half the kit cost, and has already been thoroughly tested for specified performance before it was packed.

Turn the chassis upside down, and rest it on the module and transformer to remove these parts. In- clude all of the hardware you have removed with the rest when you check off the components against the parts list in the back of this manual. We recommend this

It will simplify matters if you first separate the #4 nuts from the #6 nuts, which have the same outside dimen- sions. A #4 screw will pass through a #6 nut, aiding iden- tification.

A “set” of hardware includes one screw and one KEP nut (with its attached lockwasher). Always install the lockwasher side of the nut first. If the size of the hardware is not specified, use the # 4 size, which is the smallest. #10 is the largest. Always insert the screw from the outside of the chassis.

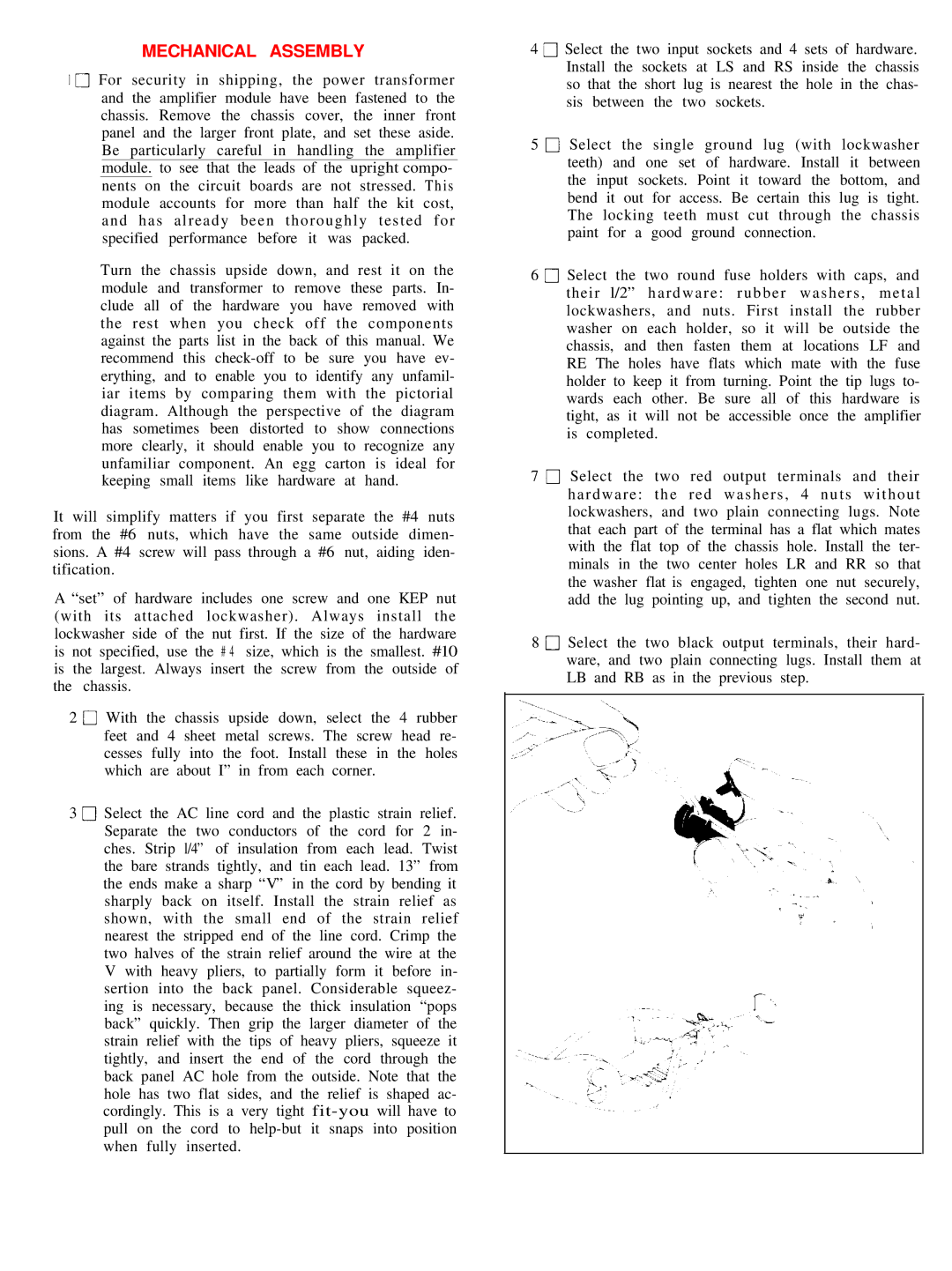

2 0 With the chassis upside down, select the 4 rubber feet and 4 sheet metal screws. The screw head re- cesses fully into the foot. Install these in the holes which are about I” in from each corner.

3 0 Select the AC line cord and the plastic strain relief. Separate the two conductors of the cord for 2 in- ches. Strip l/4” of insulation from each lead. Twist the bare strands tightly, and tin each lead. 13” from the ends make a sharp “V” in the cord by bending it sharply back on itself. Install the strain relief as shown, with the small end of the strain relief nearest the stripped end of the line cord. Crimp the two halves of the strain relief around the wire at the V with heavy pliers, to partially form it before in- sertion into the back panel. Considerable squeez- ing is necessary, because the thick insulation “pops back” quickly. Then grip the larger diameter of the strain relief with the tips of heavy pliers, squeeze it tightly, and insert the end of the cord through the back panel AC hole from the outside. Note that the hole has two flat sides, and the relief is shaped ac- cordingly. This is a very tight

4 0 Select the two input sockets and 4 sets of hardware. Install the sockets at LS and RS inside the chassis so that the short lug is nearest the hole in the chas- sis between the two sockets.

5 0 Select the single ground lug (with lockwasher teeth) and one set of hardware. Install it between the input sockets. Point it toward the bottom, and bend it out for access. Be certain this lug is tight. The locking teeth must cut through the chassis paint for a good ground connection.

6 0 Select the two round fuse holders with caps, and their l/2” h a r d w a r e : r u b b e r w a s h e r s , m e t a l lockwashers, and nuts. First install the rubber washer on each holder, so it will be outside the chassis, and then fasten them at locations LF and RE The holes have flats which mate with the fuse holder to keep it from turning. Point the tip lugs to- wards each other. Be sure all of this hardware is tight, as it will not be accessible once the amplifier is completed.

7 17 Select the two red output terminals and their h a r d w a r e : t h e r e d w a s h e r s , 4 n u t s w i t h o u t lockwashers, and two plain connecting lugs. Note that each part of the terminal has a flat which mates with the flat top of the chassis hole. Install the ter- minals in the two center holes LR and RR so that the washer flat is engaged, tighten one nut securely, add the lug pointing up, and tighten the second nut.

8 0 Select the two black output terminals, their hard- ware, and two plain connecting lugs. Install them at LB and RB as in the previous step.

T | , |

F | . |

| I |