90S e l e c t the plastic encased relay, the longer

10Select 2 sets of hardware and mount the relay near the 2 red terminals, with the bracket facing front. Install the screws from below the chassis.

11Select the 2 shorter L brackets, 4 sets of hardware, and the circuit board

12Select 2 sets of hardware and install the circuit board between the line cord and terminal RB, with the components facing to the rear.

130 Select the

140 Select the single fuse clip and a set of hardware. In- stall it in the single hole between the two “dimples” at the front of the chassis. The dimples prevent the clip from turning too far.

150 Select the 2 dual fuse clips and 4 sets of hardware. Install one of these in the pair of holes nearest the center of the chassis, and the other in the pair of holes aligned with it near the left edge.

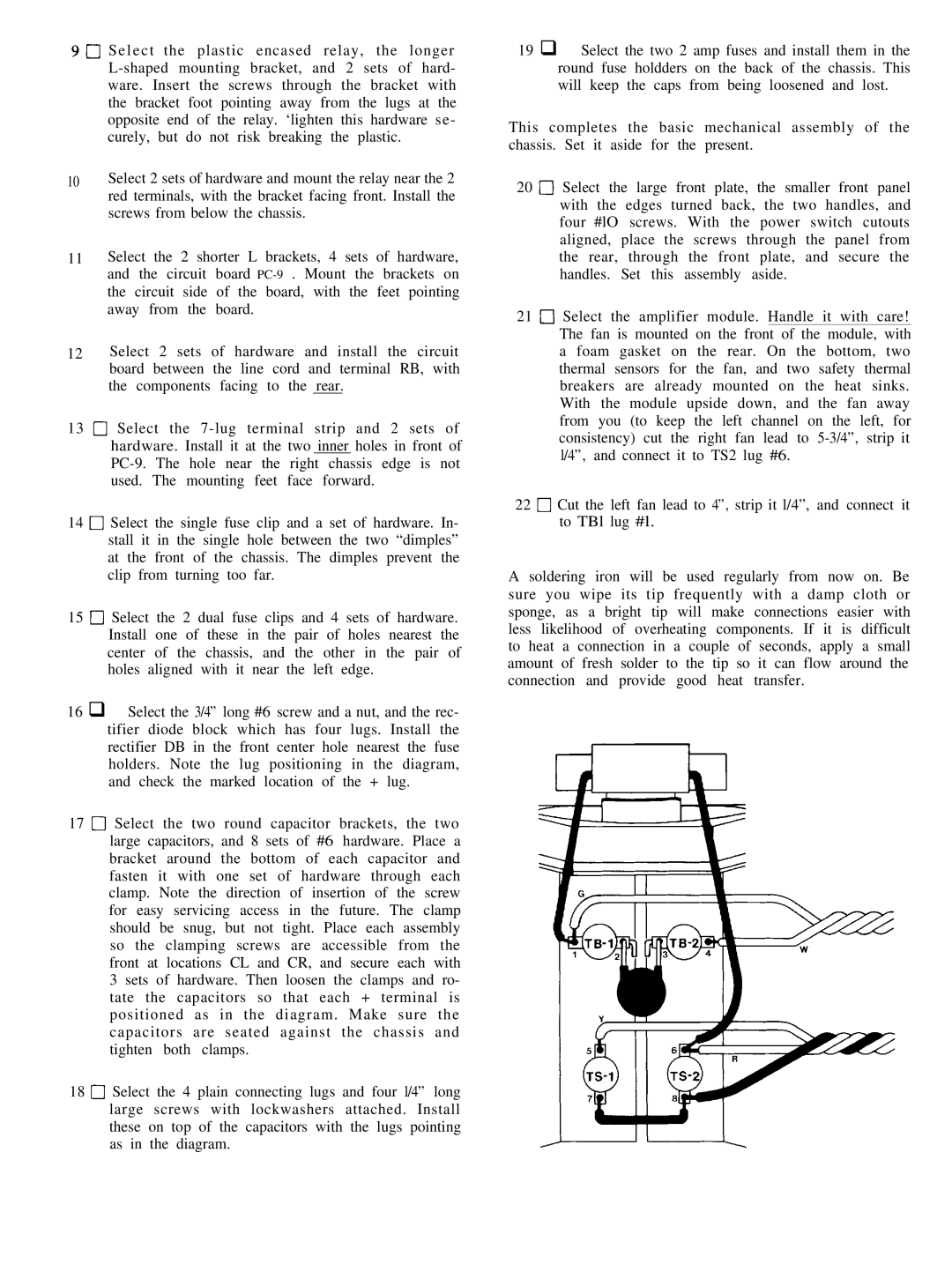

16q Select the 3/4” long #6 screw and a nut, and the rec- tifier diode block which has four lugs. Install the rectifier DB in the front center hole nearest the fuse holders. Note the lug positioning in the diagram, and check the marked location of the + lug.

17

18 0 Select the 4 plain connecting lugs and four l/4” long large screws with lockwashers attached. Install these on top of the capacitors with the lugs pointing as in the diagram.

19 q Select the two 2 amp fuses and install them in the round fuse holdders on the back of the chassis. This will keep the caps from being loosened and lost.

This completes the basic mechanical assembly of the chassis. Set it aside for the present.

20 0 Select the large front plate, the smaller front panel with the edges turned back, the two handles, and four #lO screws. With the power switch cutouts aligned, place the screws through the panel from the rear, through the front plate, and secure the handles. Set this assembly aside.

21 0 Select the amplifier module. Handle it with care! The fan is mounted on the front of the module, with a foam gasket on the rear. On the bottom, two thermal sensors for the fan, and two safety thermal breakers are already mounted on the heat sinks. With the module upside down, and the fan away from you (to keep the left channel on the left, for consistency) cut the right fan lead to

22 0 Cut the left fan lead to 4”, strip it l/4”, and connect it to TBl lug #l.

A soldering iron will be used regularly from now on. Be sure you wipe its tip frequently with a damp cloth or sponge, as a bright tip will make connections easier with less likelihood of overheating components. If it is difficult to heat a connection in a couple of seconds, apply a small amount of fresh solder to the tip so it can flow around the connection and provide good heat transfer.