Adjusting the Height of the Feed Dog

The Feed Dog is factory adjusted. If the Feed Dog juts out too much, puckering may result when sewing lightweight materials. To adjust the height of the Feed Dog:

1.Move the Feed Dog to the front end of the throat plate.

2.Loosen Screw (A) of Crank.

3.Move the Feed Dog (B) up or down to make the adjustment.

4.Tighten Screw (A), being careful not to over- tighten.

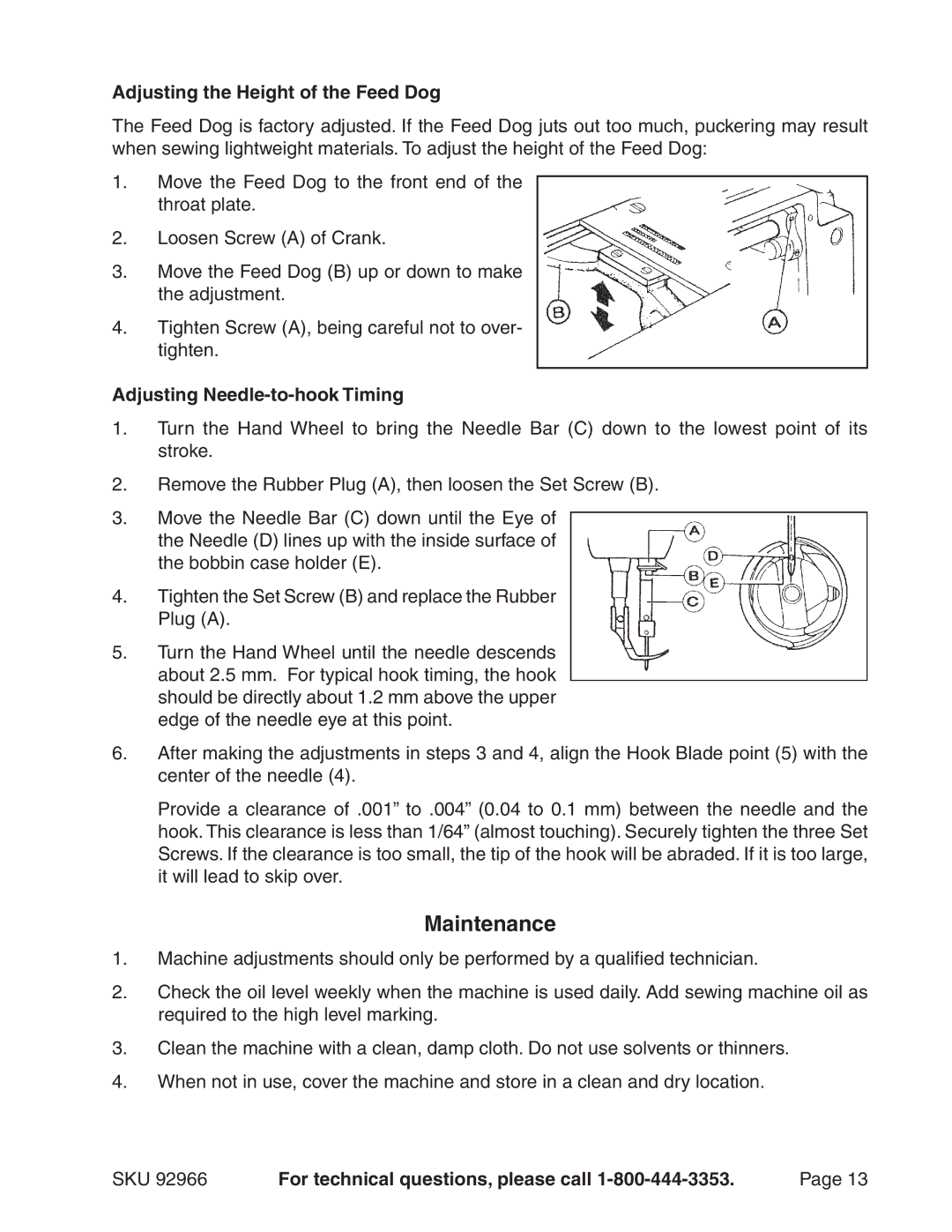

Adjusting Needle-to-hook Timing

1.Turn the Hand Wheel to bring the Needle Bar (C) down to the lowest point of its stroke.

2.Remove the Rubber Plug (A), then loosen the Set Screw (B).

3.Move the Needle Bar (C) down until the Eye of the Needle (D) lines up with the inside surface of the bobbin case holder (E).

4.Tighten the Set Screw (B) and replace the Rubber Plug (A).

5.Turn the Hand Wheel until the needle descends about 2.5 mm. For typical hook timing, the hook should be directly about 1.2 mm above the upper edge of the needle eye at this point.

6.After making the adjustments in steps 3 and 4, align the Hook Blade point (5) with the center of the needle (4).

Provide a clearance of .001” to .004” (0.04 to 0.1 mm) between the needle and the hook. This clearance is less than 1/64” (almost touching). Securely tighten the three Set Screws. If the clearance is too small, the tip of the hook will be abraded. If it is too large, it will lead to skip over.

Maintenance

1.Machine adjustments should only be performed by a qualified technician.

2.Check the oil level weekly when the machine is used daily. Add sewing machine oil as required to the high level marking.

3.Clean the machine with a clean, damp cloth. Do not use solvents or thinners.

4.When not in use, cover the machine and store in a clean and dry location.

SKU 92966 | For technical questions, please call | Page 13 |