thickness reaches

NOTE: To reset for a different depth stop, raise the Rollercase (136) by about two rotations of the Manual Elevation Handle (5). Then turn the Thickness Pre- set Control Knob (279) to the desired position. (See Figure J.)

THICKNESS PRESET CONTROL KNOB

(279)

FIGURE J

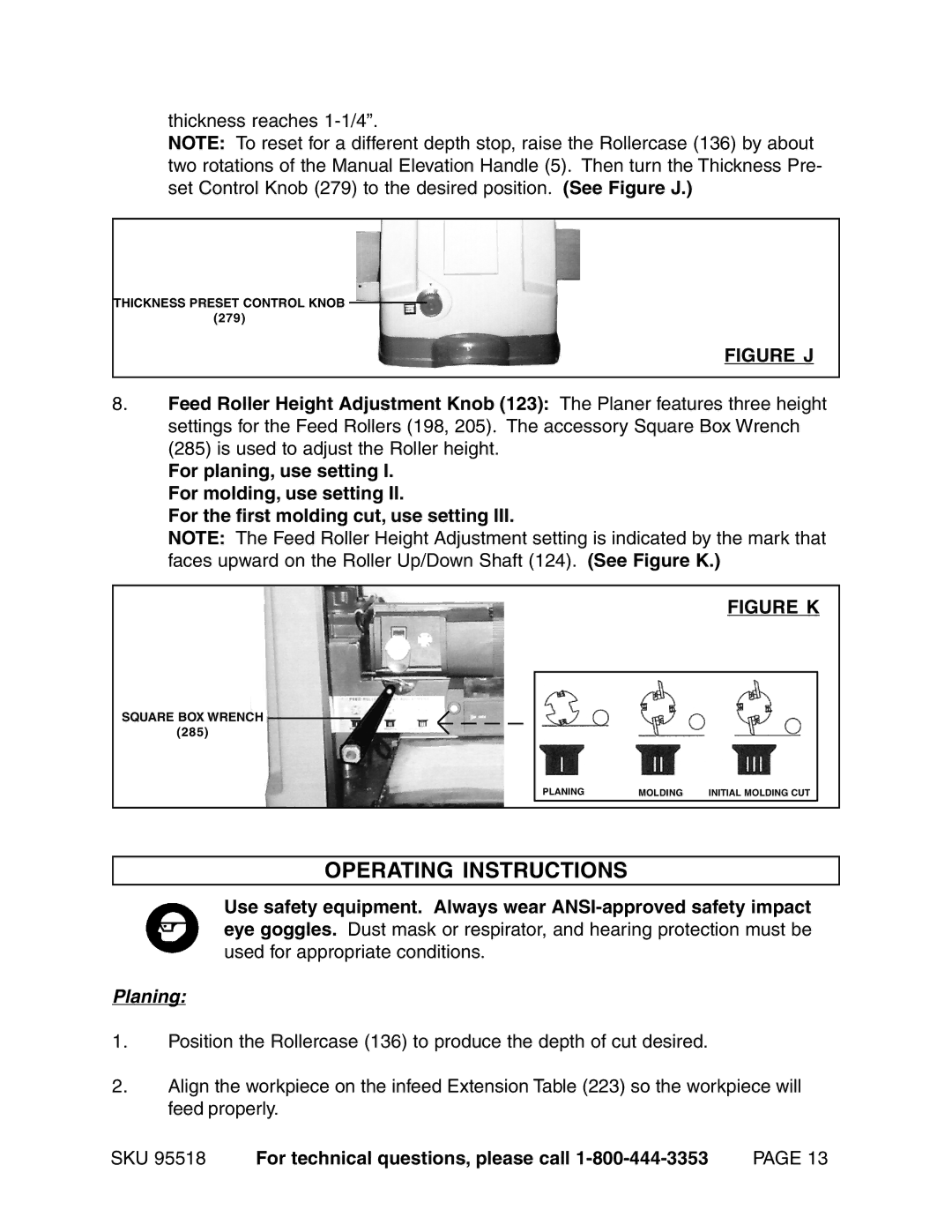

8.Feed Roller Height Adjustment Knob (123): The Planer features three height settings for the Feed Rollers (198, 205). The accessory Square Box Wrench

(285)is used to adjust the Roller height.

For planing, use setting I. For molding, use setting II.

For the first molding cut, use setting III.

NOTE: The Feed Roller Height Adjustment setting is indicated by the mark that faces upward on the Roller Up/Down Shaft (124). (See Figure K.)

FIGURE K

SQUARE BOX WRENCH

(285)

PLANING | MOLDING | INITIAL MOLDING CUT |

OPERATING INSTRUCTIONS

Use safety equipment. Always wear

Planing:

1.Position the Rollercase (136) to produce the depth of cut desired.

2.Align the workpiece on the infeed Extension Table (223) so the workpiece will feed properly.

SKU 95518 | For technical questions, please call | PAGE 13 |