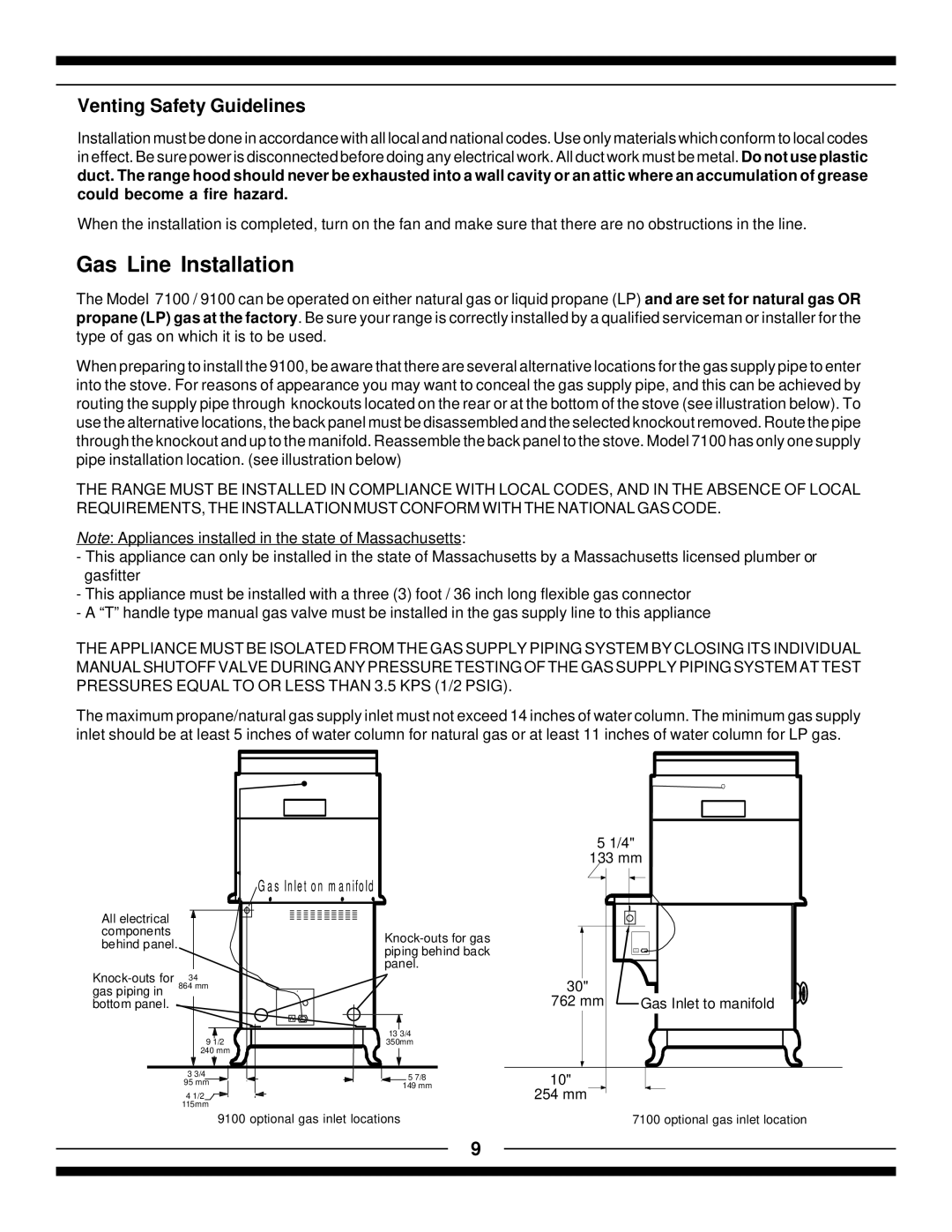

9100, 7100 specifications

Hearth and Home Technologies offers a variety of advanced heating solutions, including the 9100 and 7100 models, which exemplify the company's commitment to innovation, efficiency, and aesthetics. These gas fireplaces provide homeowners with an elegant and practical way to enhance their living spaces while enjoying the warmth and ambiance of a traditional fire.The 9100 model is known for its large viewing area, presenting a stunning flame display that serves as the focal point of any room. With a contemporary design, it easily complements modern interiors while also fitting into traditional decor. The unit features multiple style options, including linear configurations, allowing for versatility in home design. One of its key features is the IntelliFire® ignition system, which combines reliability with energy efficiency. This system ensures that the gas fireplace ignites smoothly and can be operated via a remote control, making it user-friendly.

The 7100 model, while slightly smaller, does not compromise on performance or aesthetics. It also offers a large viewing window, delivering a captivating flame experience that can transform any space into a cozy retreat. The 7100 is designed with ease of installation in mind, making it suitable for both new builds and retrofitting into existing homes. Among its notable technologies is the advanced heat management system, which allows for optimal heat distribution without compromising the fireplace's beautiful design.

Both models are engineered with efficiency in mind, featuring high AFUE (Annual Fuel Utilization Efficiency) ratings. This means they convert a significant amount of the gas used into heat, ultimately saving homeowners on energy costs while providing consistent warmth. Additionally, these units are equipped with options for custom flame presentations, allowing users to adjust flame height and color for a personalized touch.

Safety is also a primary consideration in the design of the 9100 and 7100 fireplaces. Both are equipped with safety features such as an automatic shutoff system in case of ignitions issues, ensuring peace of mind for users. The fireplaces are certified for venting flexibility, permitting various installation configurations while ensuring safety and performance standards are met.

In summary, Hearth and Home Technologies' 9100 and 7100 models are exemplary choices for those seeking modern, efficient, and aesthetically pleasing heating solutions. With advanced ignition systems, high efficiency, and customizable features, these gas fireplaces are designed to provide lasting warmth and style to any home environment.