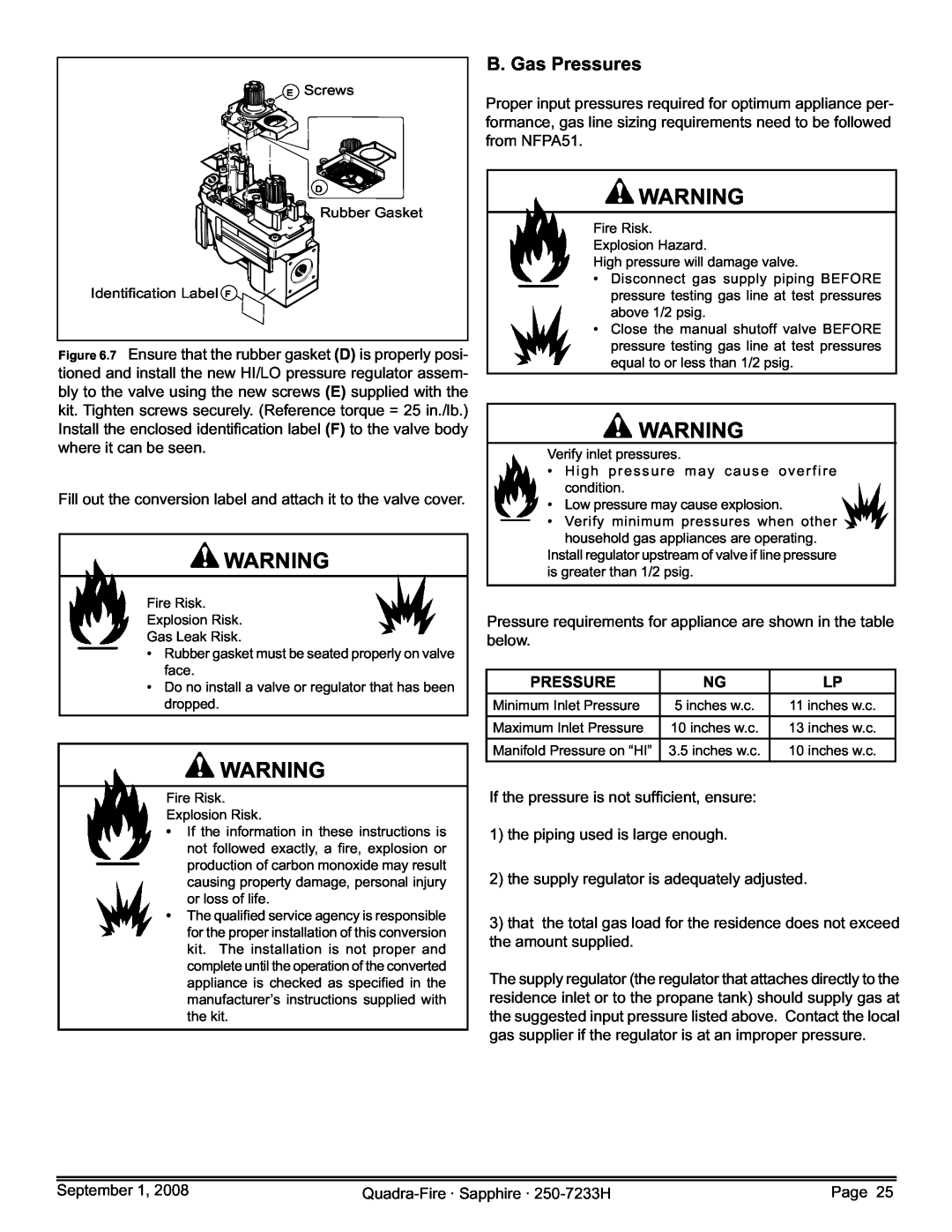

E Screws

D

Rubber Gasket

Identification Label F ![]()

![]()

Figure 6.7 Ensure that the rubber gasket (D) is properly posi- tioned and install the new HI/LO pressure regulator assem- bly to the valve using the new screws (E) supplied with the kit. Tighten screws securely. (Reference torque = 25 in./lb.) Install the enclosed identification label (F) to the valve body where it can be seen.

Fill out the conversion label and attach it to the valve cover.

![]() WARNING

WARNING

Fire Risk.

Explosion Risk.

Gas Leak Risk.

•Rubber gasket must be seated properly on valve face.

•Do no install a valve or regulator that has been dropped.

![]() WARNING

WARNING

Fire Risk.

Explosion Risk.

•If the information in these instructions is not followed exactly, a fire, explosion or production of carbon monoxide may result causing property damage, personal injury or loss of life.

•The qualified service agency is responsible for the proper installation of this conversion kit. The installation is not proper and complete until the operation of the converted appliance is checked as specified in the manufacturer’s instructions supplied with the kit.

B. Gas Pressures

Proper input pressures required for optimum appliance per- formance, gas line sizing requirements need to be followed from NFPA51.

![]() WARNING

WARNING

Fire Risk.

Explosion Hazard.

High pressure will damage valve.

•Disconnect gas supply piping BEFORE pressure testing gas line at test pressures

above 1/2 psig.

• Close the manual shutoff valve BEFORE pressure testing gas line at test pressures equal to or less than 1/2 psig.

![]() WARNING

WARNING

Verify inlet pressures.

•High pressure may cause overfire condition.

• Low pressure may cause explosion.

•Verify minimum pressures when other household gas appliances are operating.

Install regulator upstream of valve if line pressure is greater than 1/2 psig.

Pressure requirements for appliance are shown in the table below.

PRESSURE | NG | LP |

Minimum Inlet Pressure | 5 inches w.c. | 11 inches w.c. |

Maximum Inlet Pressure | 10 inches w.c. | 13 inches w.c. |

Manifold Pressure on “HI” | 3.5 inches w.c. | 10 inches w.c. |

If the pressure is not sufficient, ensure:

1)the piping used is large enough.

2)the supply regulator is adequately adjusted.

3)that the total gas load for the residence does not exceed the amount supplied.

The supply regulator (the regulator that attaches directly to the residence inlet or to the propane tank) should supply gas at the suggested input pressure listed above. Contact the local gas supplier if the regulator is at an improper pressure.

September 1, 2008 | Page 25 |