SL-350TRSI-AUE specifications

The Hearth and Home Technologies SL-350TRSI-AUE is a remarkable addition to the realm of contemporary fireplace solutions, designed to enhance both aesthetics and functionality in homes. This model exemplifies the company’s commitment to creating high-quality heating appliances that not only provide warmth but also serve as a stunning centerpiece for any living space.One of the key features of the SL-350TRSI-AUE is its state-of-the-art linear design. This fireplace is constructed to provide a clean, modern aesthetic that seamlessly integrates into a variety of interior styles. With a sleek frame and expansive glass viewing area, it offers a panoramic view of the flames, allowing for an immersive experience. The linear orientation also creates a more open feel in a room, making it a favored choice for contemporary living spaces.

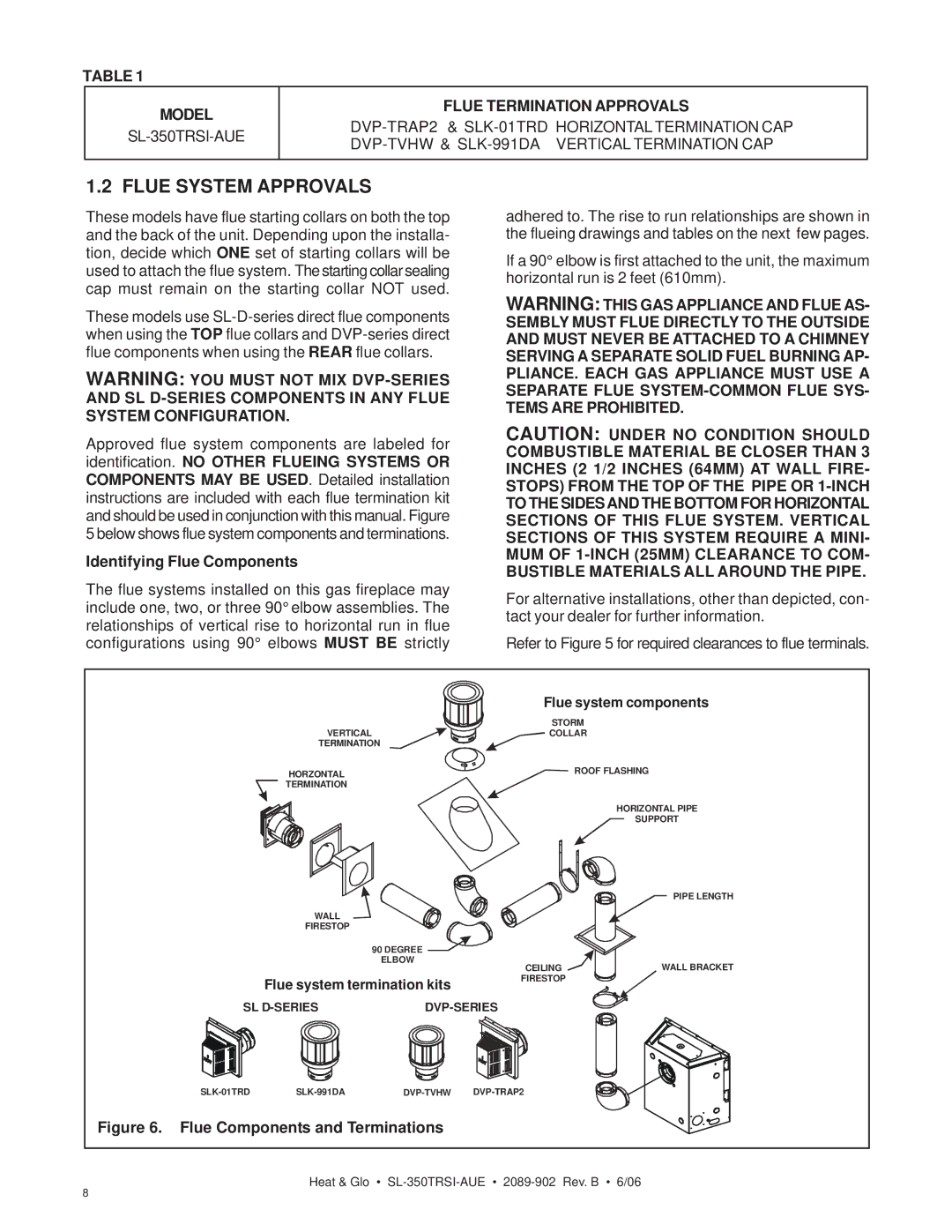

In terms of technology, the SL-350TRSI-AUE is equipped with advanced direct vent capabilities, ensuring efficient combustion and enhanced safety. The direct vent system pulls air from outside for combustion and exhausts directly outside, maintaining indoor air quality and optimizing heating efficiency. This is particularly beneficial in energy-smart homes, where maintaining indoor air quality is paramount.

The fireplace also features a powerful, adjustable flame control, enabling users to customize their heating experience according to personal preferences. With its thermostat compatibility, homeowners can set their desired temperature, and the fireplace will automatically adjust to provide consistent warmth. This smart heating solution ensures comfort throughout the colder months while also keeping energy consumption in check.

With regard to installation, the SL-350TRSI-AUE offers versatility. Its flexible venting options allow for installation in various locations, whether it be on an exterior wall or in a basement. The unit is designed to work under a variety of building conditions, providing engineers and contractors with greater flexibility during the design and installation processes.

Additionally, the fireplace features a minimalist remote control, allowing users to operate the unit effortlessly from anywhere in the room. The combination of these features makes the Hearth and Home Technologies SL-350TRSI-AUE a practical yet stylish choice for those seeking an efficient and visually appealing heating solution. With its blend of modern design, advanced technology, and functionality, it stands out as an exemplary product in the competitive fireplace market.