6Gas Information

A. Fuel Conversion | C. Gas Connection |

Before making gas connections ensure appliance being in- stalled is compatible with the available gas type.

Any natural or propane gas conversions necessary to meet the appliance and locality needs must be made by a quali-

fied technician using Hearth & Home Technologies specifi ed and approved parts.

Note: Have the gas supply line installed in accordance with local building codes, if any. If not, follow ANSI 223.1. Installation should be done by a qualifi ed installer approved and/or licensed as required by the locality. (In the Commonwealth of Massachusetts installation must be performed by a licensed plumber or gas fi tter.)

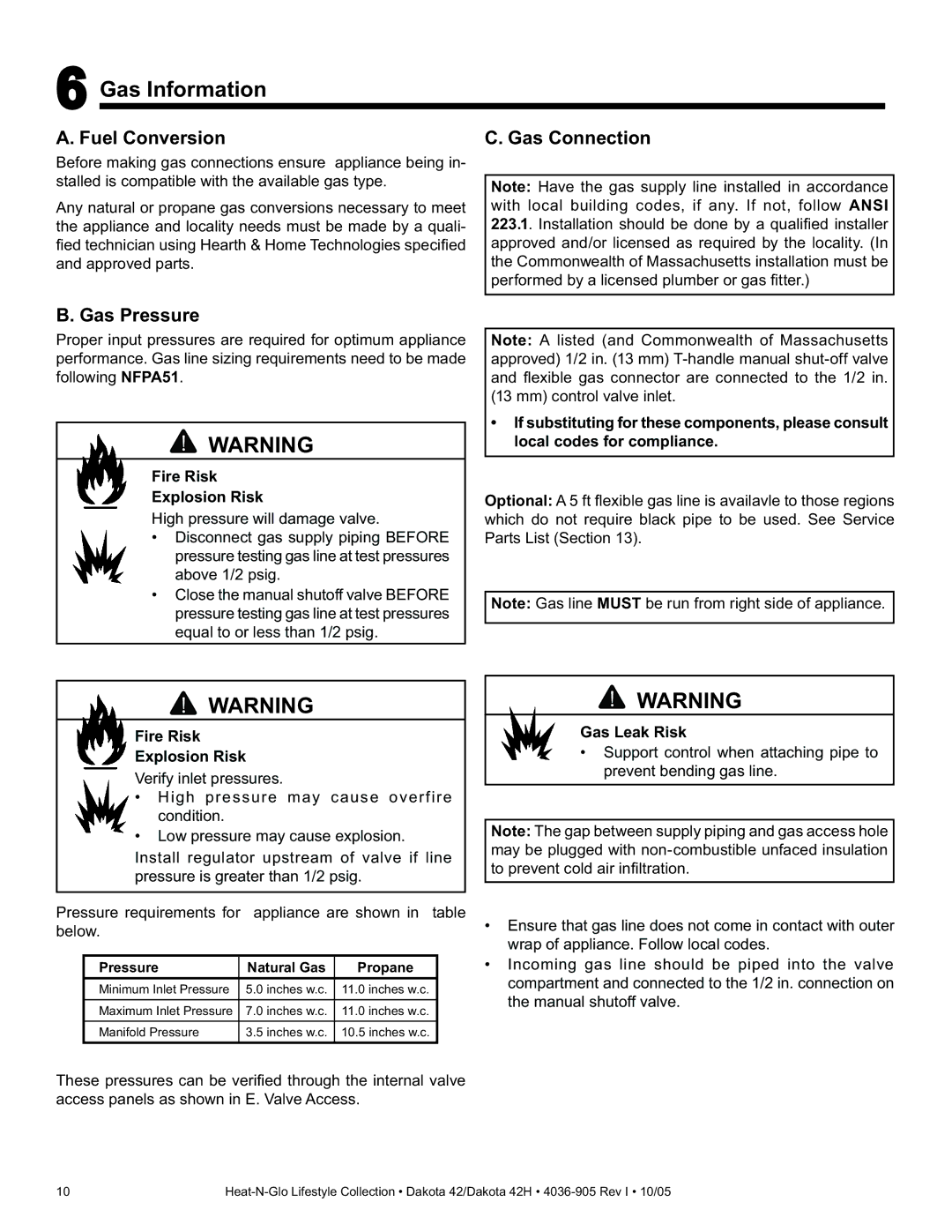

B. Gas Pressure

Proper input pressures are required for optimum appliance performance. Gas line sizing requirements need to be made following NFPA51.

![]() WARNING

WARNING

Fire Risk

Explosion Risk

High pressure will damage valve.

•Disconnect gas supply piping BEFORE pressure testing gas line at test pressures above 1/2 psig.

•Close the manual shutoff valve BEFORE pressure testing gas line at test pressures equal to or less than 1/2 psig.

Note: A listed (and Commonwealth of Massachusetts approved) 1/2 in. (13 mm)

•If substituting for these components, please consult local codes for compliance.

Optional: A 5 ft fl exible gas line is availavle to those regions which do not require black pipe to be used. See Service Parts List (Section 13).

Note: Gas line MUST be run from right side of appliance.

![]() WARNING

WARNING

Fire Risk

Explosion Risk

Verify inlet pressures.

•High pressure may cause overfire condition.

•Low pressure may cause explosion.

Install regulator upstream of valve if line pressure is greater than 1/2 psig.

Pressure requirements for | appliance are shown in table | ||||

below. |

|

|

| ||

|

|

|

|

|

|

| Pressure |

| Natural Gas | Propane |

|

| Minimum Inlet Pressure |

| 5.0 inches w.c. | 11.0 inches w.c. |

|

| Maximum Inlet Pressure |

| 7.0 inches w.c. | 11.0 inches w.c. |

|

|

|

|

|

|

|

| Manifold Pressure |

| 3.5 inches w.c. | 10.5 inches w.c. |

|

These pressures can be verifi ed through the internal valve access panels as shown in E. Valve Access.

![]() WARNING

WARNING

Gas Leak Risk

•Support control when attaching pipe to prevent bending gas line.

Note: The gap between supply piping and gas access hole may be plugged with

•Ensure that gas line does not come in contact with outer wrap of appliance. Follow local codes.

•Incoming gas line should be piped into the valve compartment and connected to the 1/2 in. connection on the manual shutoff valve.

10 |