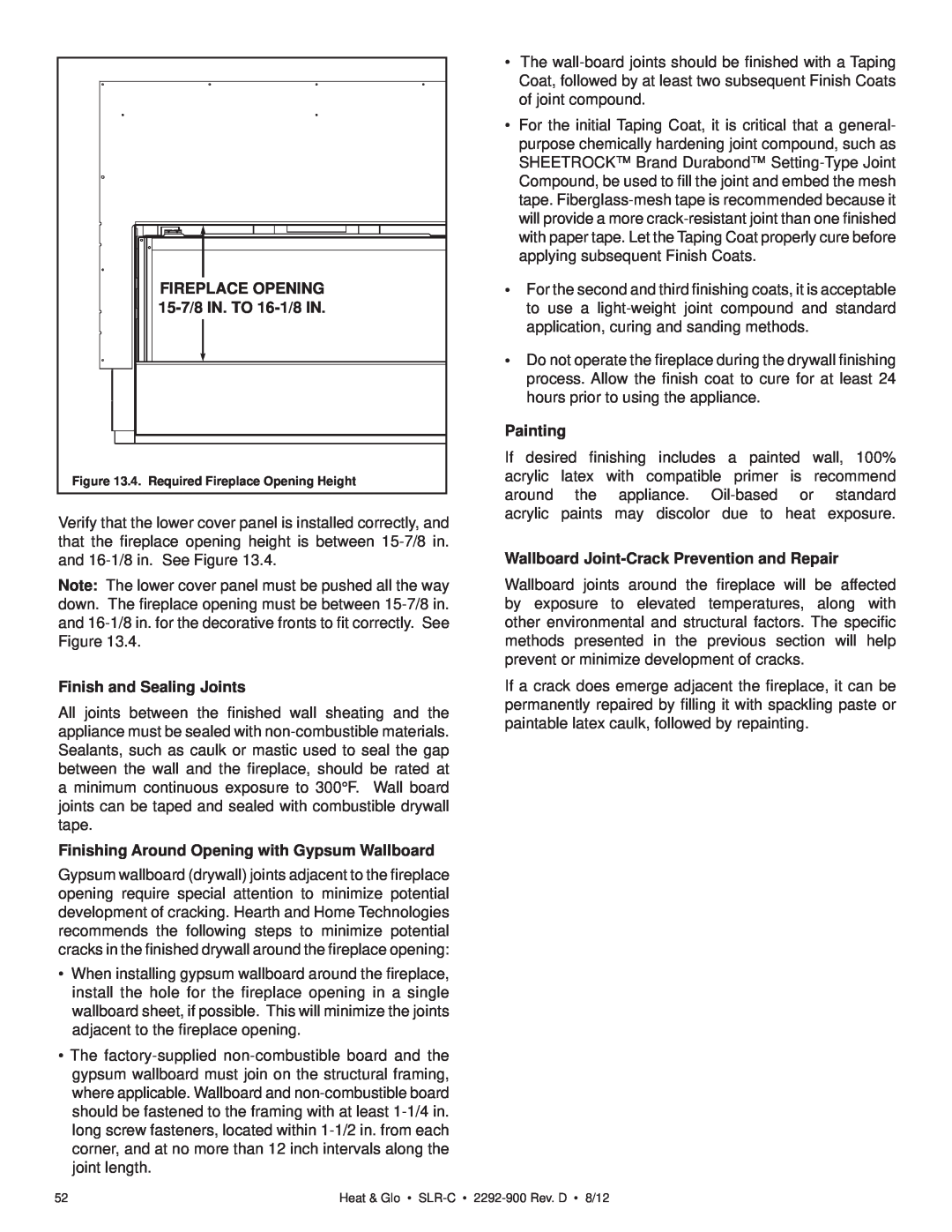

FIREPLACE OPENING |

|

Figure 13.4. Required Fireplace Opening Height

Verify that the lower cover panel is installed correctly, and that the fireplace opening height is between

Note: The lower cover panel must be pushed all the way down. The fireplace opening must be between

Finish and Sealing Joints

All joints between the finished wall sheating and the appliance must be sealed with

Finishing Around Opening with Gypsum Wallboard

Gypsum wallboard (drywall) joints adjacent to the fireplace opening require special attention to minimize potential development of cracking. Hearth and Home Technologies recommends the following steps to minimize potential cracks in the finished drywall around the fireplace opening:

•When installing gypsum wallboard around the fireplace, install the hole for the fireplace opening in a single wallboard sheet, if possible. This will minimize the joints adjacent to the fireplace opening.

•The

•The

•For the initial Taping Coat, it is critical that a general- purpose chemically hardening joint compound, such as SHEETROCK™ Brand Durabond™

•For the second and third finishing coats, it is acceptable to use a

•Do not operate the fireplace during the drywall finishing process. Allow the finish coat to cure for at least 24 hours prior to using the appliance.

Painting

If desired finishing includes a painted wall, 100% acrylic latex with compatible primer is recommend around the appliance.

Wallboard Joint-Crack Prevention and Repair

Wallboard joints around the fireplace will be affected by exposure to elevated temperatures, along with other environmental and structural factors. The specific methods presented in the previous section will help prevent or minimize development of cracks.

If a crack does emerge adjacent the fireplace, it can be permanently repaired by filling it with spackling paste or paintable latex caulk, followed by repainting.

52 | Heat & Glo • |