OPERATION

BASIC SAW OPERATIONS

RAISE THE BLADE (Fig. U)

To raise or lower the blade, turn the blade elevation handwheel (1) to the desired blade height, and then tighten the bevel lock handle (2) to maintain the desired blade angle.

Fig. U

1

2

3

TILTING THE BLADE

1.To tilt the saw blade for bevel cutting, loosen the lock knob (2) and turn the tilting handwheel (3).

2.Tighten the lock knobs (2) to secure.

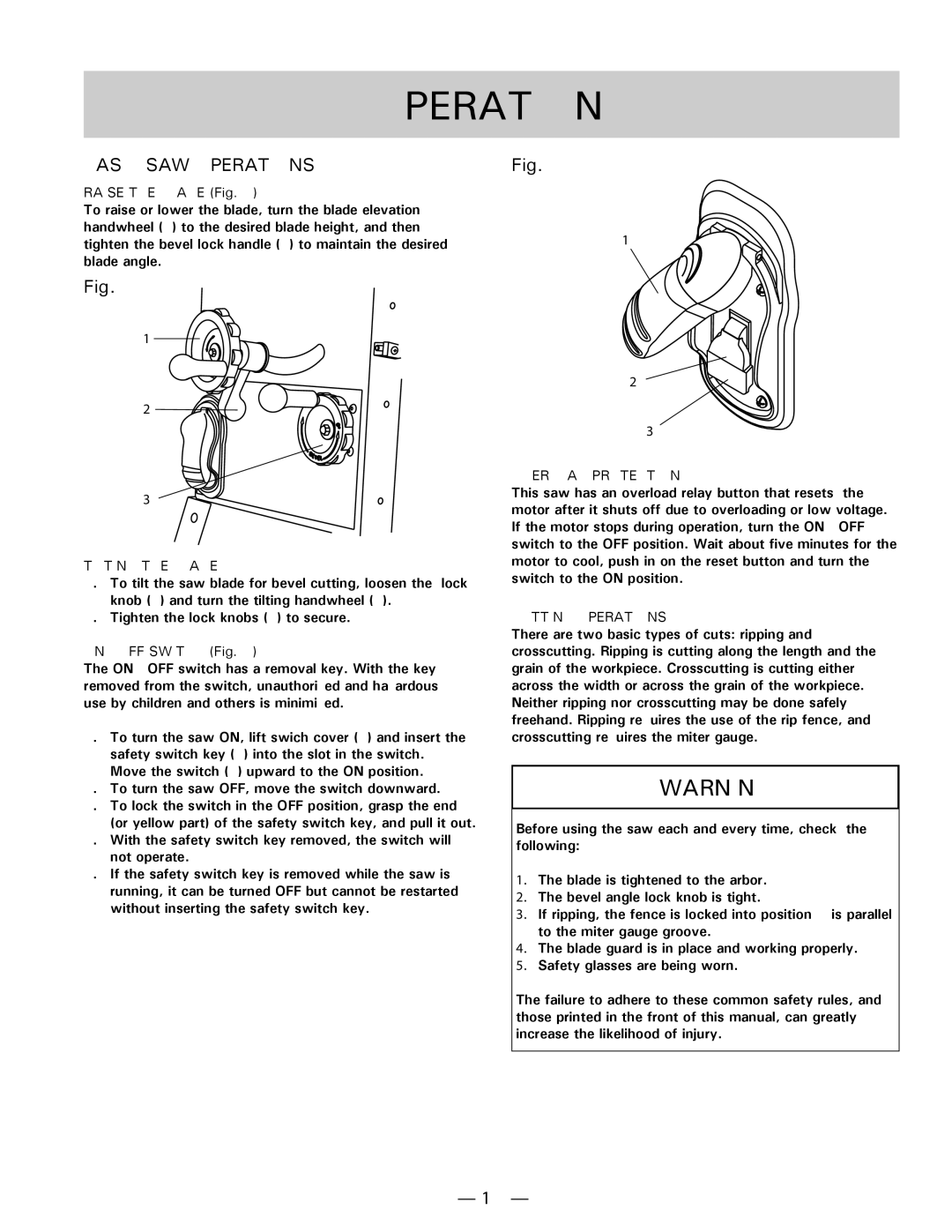

ON / OFF SWITCH (Fig. V)

The ON / OFF switch has a removal key. With the key removed from the switch, unauthorized and hazardous use by children and others is minimized.

1.To turn the saw ON, lift swich cover (1) and insert the safety switch key (2) into the slot in the switch. Move the switch (3) upward to the ON position.

2.To turn the saw OFF, move the switch downward.

3.To lock the switch in the OFF position, grasp the end (or yellow part) of the safety switch key, and pull it out.

4.With the safety switch key removed, the switch will not operate.

5.If the safety switch key is removed while the saw is running, it can be turned OFF but cannot be restarted without inserting the safety switch key.

Fig. V

1

2

3

OVERLOAD PROTECTION

This saw has an overload relay button that resets the motor after it shuts off due to overloading or low voltage. If the motor stops during operation, turn the ON / OFF switch to the OFF position. Wait about five minutes for the motor to cool, push in on the reset button and turn the switch to the ON position.

CUTTING OPERATIONS

There are two basic types of cuts: ripping and crosscutting. Ripping is cutting along the length and the grain of the workpiece. Crosscutting is cutting either across the width or across the grain of the workpiece. Neither ripping nor crosscutting may be done safely freehand. Ripping requires the use of the rip fence, and crosscutting requires the miter gauge.

![]() WARNING

WARNING

Before using the saw each and every time, check the following:

1.The blade is tightened to the arbor.

2.The bevel angle lock knob is tight.

3.If ripping, the fence is locked into position & is parallel to the miter gauge groove.

4.The blade guard is in place and working properly.

5.Safety glasses are being worn.

The failure to adhere to these common safety rules, and those printed in the front of this manual, can greatly increase the likelihood of injury.

— 19 —