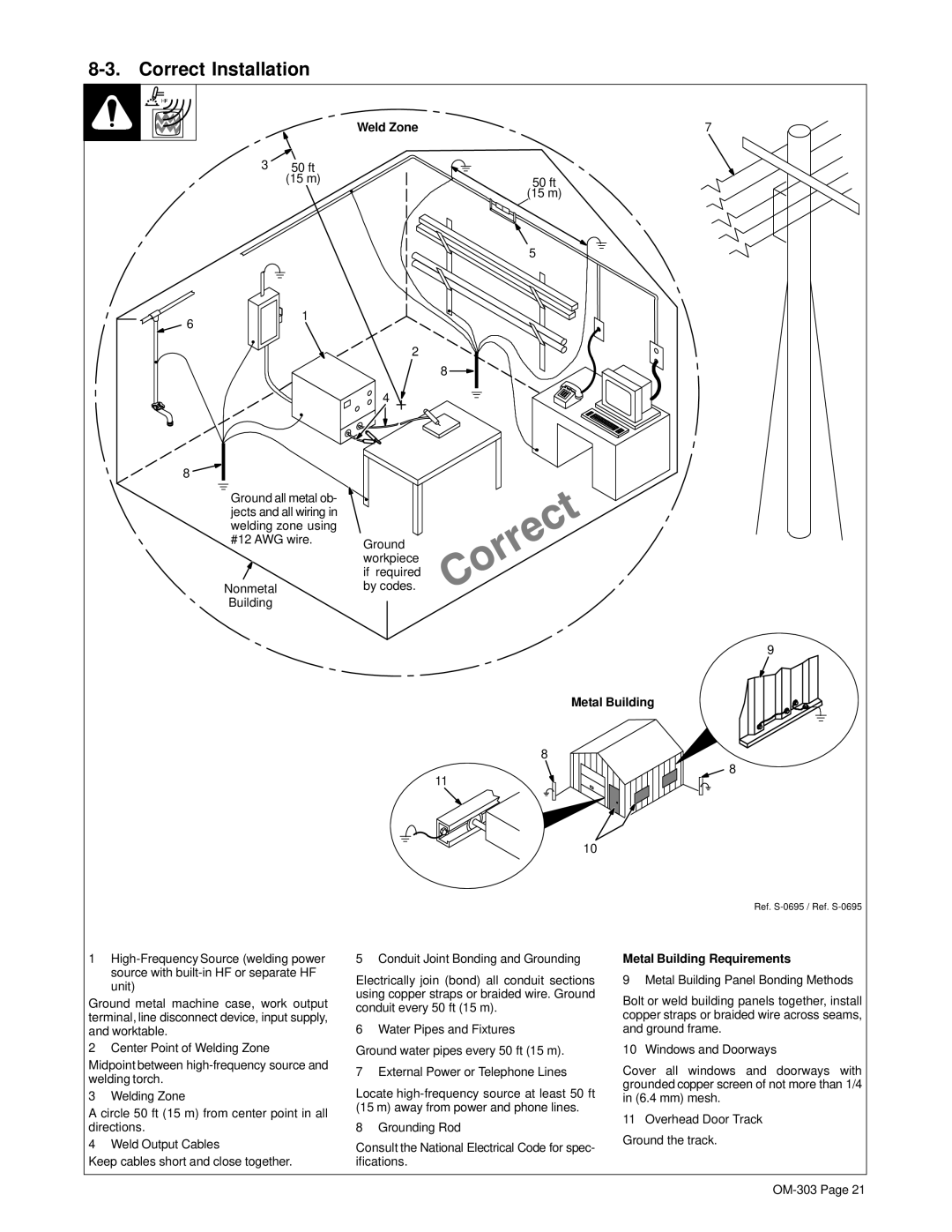

8-3. Correct Installation

3 | 50 ft |

| (15 m) |

Weld Zone

7

50ft

(15 m)

5

![]() 6

6

8

1

2

8

4

Ground all metal ob- jects and all wiring in welding zone using #12 AWG wire.

Nonmetal

Building

Ground workpiece if required by codes.

11

9

Metal Building

8

![]() 8

8

10

Ref.

1

Ground metal machine case, work output terminal, line disconnect device, input supply, and worktable.

2 Center Point of Welding Zone

Midpoint between

3 Welding Zone

A circle 50 ft (15 m) from center point in all directions.

4 Weld Output Cables

Keep cables short and close together.

5 Conduit Joint Bonding and Grounding

Electrically join (bond) all conduit sections using copper straps or braided wire. Ground conduit every 50 ft (15 m).

6 Water Pipes and Fixtures

Ground water pipes every 50 ft (15 m).

7 External Power or Telephone Lines

Locate

8 Grounding Rod

Consult the National Electrical Code for spec- ifications.

Metal Building Requirements

9 Metal Building Panel Bonding Methods

Bolt or weld building panels together, install copper straps or braided wire across seams, and ground frame.

10 Windows and Doorways

Cover all windows and doorways with grounded copper screen of not more than 1/4 in (6.4 mm) mesh.

11 Overhead Door Track

Ground the track.