2 1

3

9 | 8 |

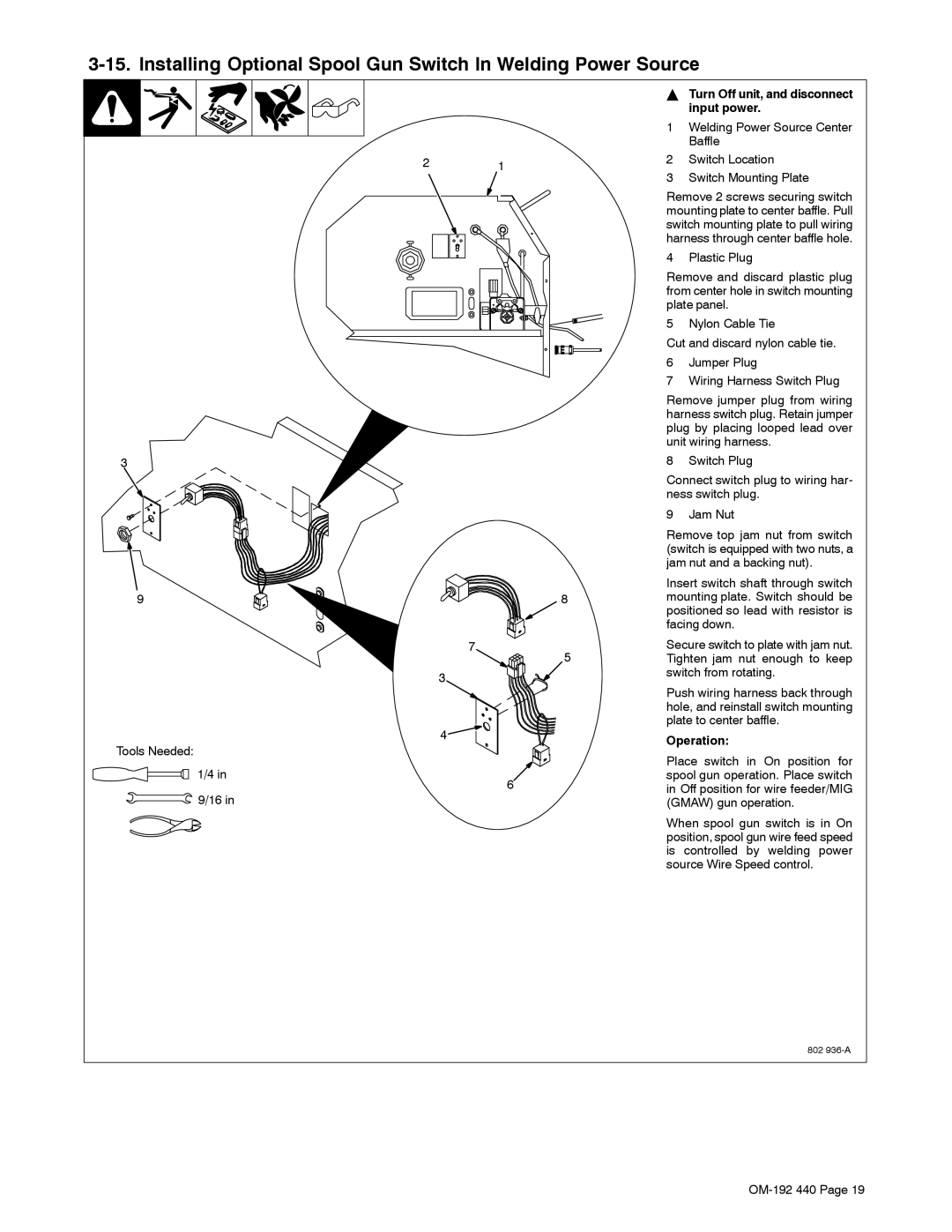

YTurn Off unit, and disconnect input power.

1Welding Power Source Center Baffle

2Switch Location

3Switch Mounting Plate

Remove 2 screws securing switch mounting plate to center baffle. Pull switch mounting plate to pull wiring harness through center baffle hole.

4 Plastic Plug

Remove and discard plastic plug from center hole in switch mounting plate panel.

5 Nylon Cable Tie

Cut and discard nylon cable tie.

6Jumper Plug

7Wiring Harness Switch Plug

Remove jumper plug from wiring harness switch plug. Retain jumper plug by placing looped lead over unit wiring harness.

8 Switch Plug

Connect switch plug to wiring har- ness switch plug.

9 Jam Nut

Remove top jam nut from switch (switch is equipped with two nuts, a jam nut and a backing nut).

Insert switch shaft through switch mounting plate. Switch should be positioned so lead with resistor is facing down.

7

3

5

Secure switch to plate with jam nut. Tighten jam nut enough to keep switch from rotating.

4![]()

Tools Needed:

1/4 in

6

9/16 in

Push wiring harness back through hole, and reinstall switch mounting plate to center baffle.

Operation:

Place switch in On position for spool gun operation. Place switch in Off position for wire feeder/MIG (GMAW) gun operation.

When spool gun switch is in On position, spool gun wire feed speed is controlled by welding power source Wire Speed control.

802