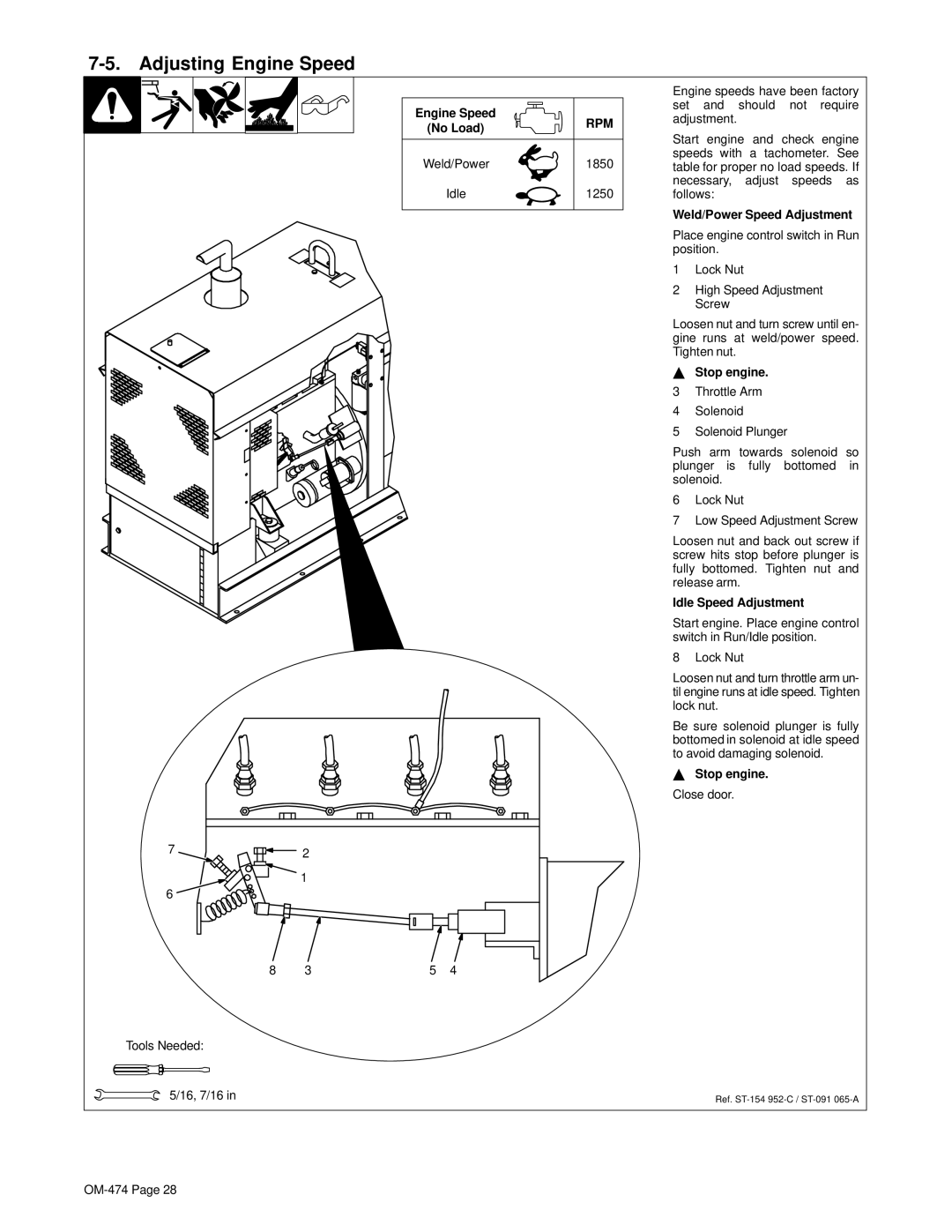

7-5. Adjusting Engine Speed

Engine Speed

(No Load)

Weld/Power

Idle

7 | 2 |

| |

| 1 |

6 |

|

8 | 3 | 5 | 4 |

Tools Needed:

5/16, 7/16 in

| Engine speeds have been factory | |

| set and should not require | |

RPM | adjustment. | |

|

| |

| Start engine and check engine | |

1850 | speeds with a tachometer. See | |

table for proper no load speeds. If | ||

1250 | necessary, adjust speeds as | |

follows: | ||

| Weld/Power Speed Adjustment | |

| Place engine control switch in Run | |

| position. | |

| 1 | Lock Nut |

| 2 | High Speed Adjustment |

|

| Screw |

| Loosen nut and turn screw until en- | |

| gine runs at weld/power speed. | |

| Tighten nut. | |

| Y Stop engine. | |

| 3 | Throttle Arm |

| 4 | Solenoid |

| 5 | Solenoid Plunger |

| Push arm towards solenoid so | |

| plunger is fully bottomed in | |

| solenoid. | |

| 6 | Lock Nut |

| 7 | Low Speed Adjustment Screw |

| Loosen nut and back out screw if | |

| screw hits stop before plunger is | |

| fully bottomed. Tighten nut and | |

| release arm. | |

| Idle Speed Adjustment | |

| Start engine. Place engine control | |

| switch in Run/Idle position. | |

| 8 | Lock Nut |

| Loosen nut and turn throttle arm un- | |

| til engine runs at idle speed. Tighten | |

| lock nut. | |

Be sure solenoid plunger is fully bottomed in solenoid at idle speed to avoid damaging solenoid.

Y Stop engine.

Close door.

Ref.