INTRODUCTION IMPORTANT

PRECAUTIONS

ASSEMBLY

BEFORE ASCENT TRAINER CONDITIONING TROUBLESHOOTING LIMITED

YOU BEGIN OPERATION GUIDELINES & MAINTENANCE WARRANTY

14

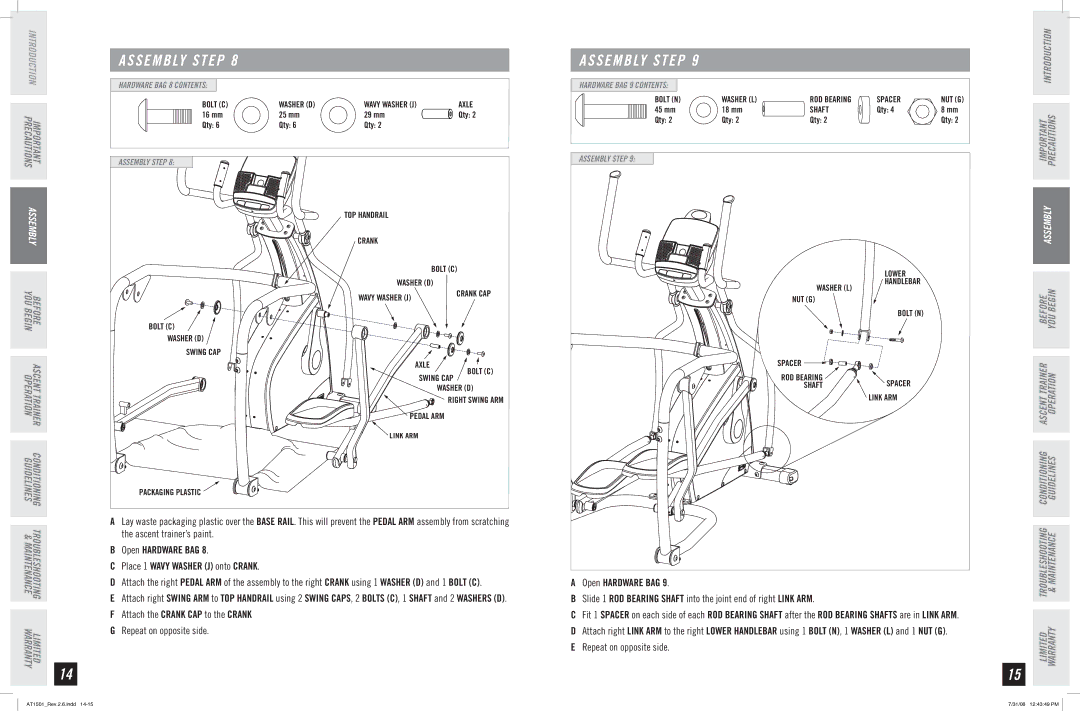

ASSEMBLY STEP 8

HARDWARE BAG 8 CONTENTS: |

|

|

|

BOLT (C) | WASHER (D) | WAVY WASHER (J) | AXLE |

16 mm | 25 mm | 29 mm | Qty: 2 |

Qty: 6 | Qty: 6 | Qty: 2 |

|

ASSEMBLY STEP 8:

TOP HANDRAIL

CRANK

| BOLT (C) |

WASHER (D) | |

WAVY WASHER (J) | CRANK CAP |

| |

BOLT (C)

WASHER (D)

SWING CAP

AXLE

BOLT (C)

SWING CAP

WASHER (D)

RIGHT SWING ARM

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() PEDAL ARM

PEDAL ARM

![]() LINK ARM

LINK ARM

PACKAGING PLASTIC ![]()

ALay waste packaging plastic over the BASE RAIL. This will prevent the PEDAL ARM assembly from scratching the ascent trainer’s paint.

BOpen HARDWARE BAG 8.

CPlace 1 WAVY WASHER (J) onto CRANK.

DAttach the right PEDAL ARM of the assembly to the right CRANK using 1 WASHER (D) and 1 BOLT (C).

EAttach right SWING ARM to TOP HANDRAIL using 2 SWING CAPS, 2 BOLTS (C), 1 SHAFT and 2 WASHERS (D).

FAttach the CRANK CAP to the CRANK

GRepeat on opposite side.

ASSEMBLY STEP 9

HARDWARE BAG 9 CONTENTS: |

|

|

|

|

BOLT (N) | WASHER (L) | ROD BEARING | SPACER | NUT (G) |

45 mm | 18 mm | SHAFT | Qty: 4 | 8 mm |

Qty: 2 | Qty: 2 | Qty: 2 |

| Qty: 2 |

ASSEMBLY STEP 9:

LOWER

HANDLEBAR

WASHER (L)

NUT (G)

BOLT (N)

SPACER |

|

ROD BEARING | SPACER |

SHAFT | |

| LINK ARM |

AOpen HARDWARE BAG 9.

BSlide 1 ROD BEARING SHAFT into the joint end of right LINK ARM.

CFit 1 SPACER on each side of each ROD BEARING SHAFT after the ROD BEARING SHAFTS are in LINK ARM.

DAttach right LINK ARM to the right LOWER HANDLEBAR using 1 BOLT (N), 1 WASHER (L) and 1 NUT (G).

ERepeat on opposite side.

15

IMPORTANT PRECAUTIONS INTRODUCTION

ASSEMBLY

LIMITED TROUBLESHOOTING CONDITIONING ASCENT TRAINER BEFORE WARRANTY & MAINTENANCE GUIDELINES OPERATION YOU BEGIN

AT1501_Rev.2.6.indd | 7/31/08 12:43:49 PM |