CL: Current Limit with I2t Shutdown

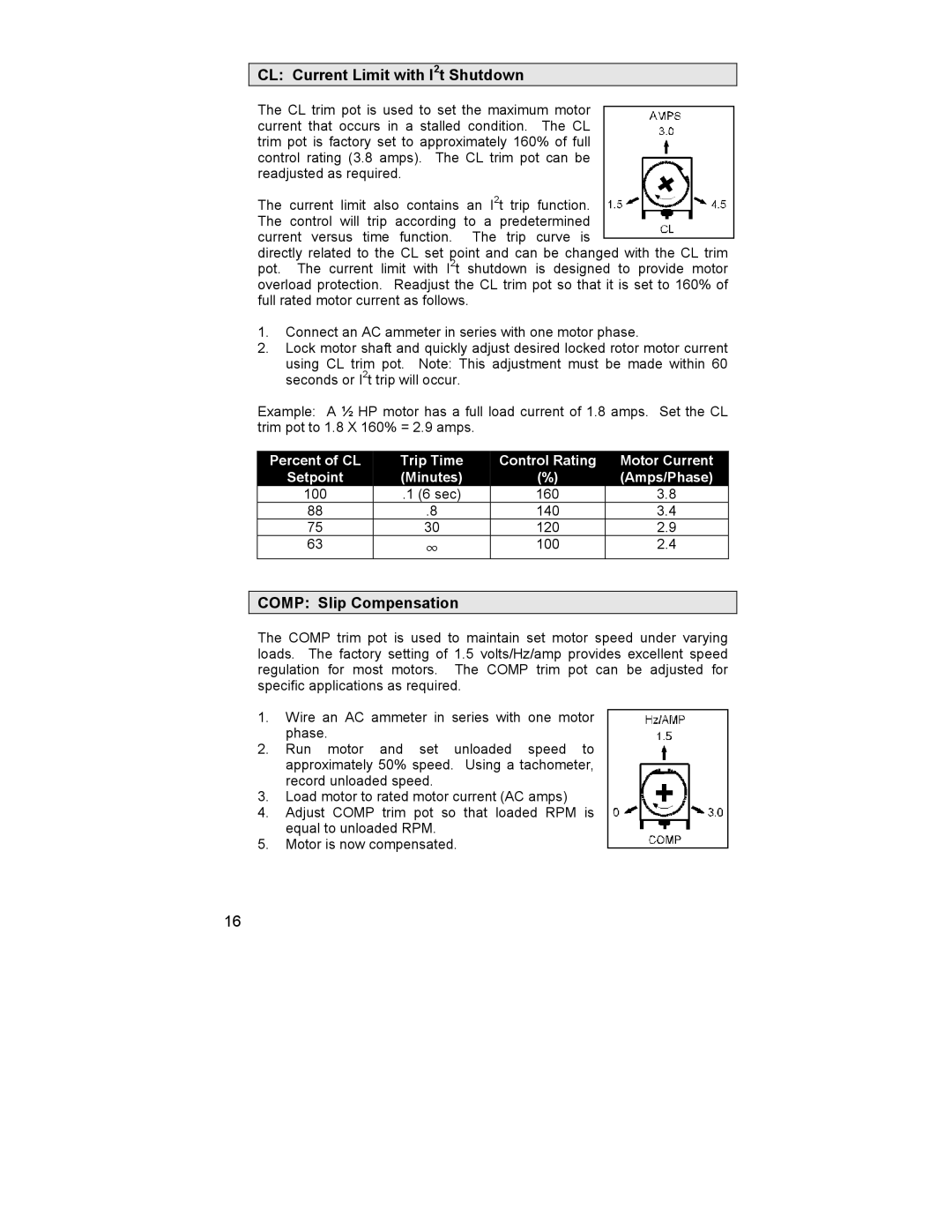

The CL trim pot is used to set the maximum motor current that occurs in a stalled condition. The CL trim pot is factory set to approximately 160% of full control rating (3.8 amps). The CL trim pot can be readjusted as required.

The current limit also contains an I2t trip function. The control will trip according to a predetermined current versus time function. The trip curve is

directly related to the CL set point and can be changed with the CL trim pot. The current limit with I2t shutdown is designed to provide motor overload protection. Readjust the CL trim pot so that it is set to 160% of full rated motor current as follows.

1.Connect an AC ammeter in series with one motor phase.

2.Lock motor shaft and quickly adjust desired locked rotor motor current using CL trim pot. Note: This adjustment must be made within 60 seconds or I2t trip will occur.

Example: A ½ HP motor has a full load current of 1.8 amps. Set the CL trim pot to 1.8 X 160% = 2.9 amps.

Percent of CL | Trip Time | Control Rating | Motor Current |

Setpoint | (Minutes) | (%) | (Amps/Phase) |

100 | .1 (6 sec) | 160 | 3.8 |

88 | .8 | 140 | 3.4 |

75 | 30 | 120 | 2.9 |

63 | 4 | 100 | 2.4 |

COMP: Slip Compensation

The COMP trim pot is used to maintain set motor speed under varying loads. The factory setting of 1.5 volts/Hz/amp provides excellent speed regulation for most motors. The COMP trim pot can be adjusted for specific applications as required.

1.Wire an AC ammeter in series with one motor phase.

2.Run motor and set unloaded speed to approximately 50% speed. Using a tachometer, record unloaded speed.

3.Load motor to rated motor current (AC amps)

4.Adjust COMP trim pot so that loaded RPM is equal to unloaded RPM.

5.Motor is now compensated.

16