4.Connect a manometer to gas control outlet (manifold) pressure tap.

5.Set room thermostat to its highest temperature.

6.Turn on electricity at electrical disconnect switch located next to furnace.

7.Diagnostic light on Fan Timer should be on and cycling

8.Draft inducer should run and pilot igniter should glow but pilot burner should not light. Manifold pressure should remain at zero.

9.Turn gas control switch to ON position.

10.Pilot burner should light and ignite main burners. It may take several minutes to purge gas line before pilot burner lights. Wait 30 seconds after main burner ignition for main blower to start.

11.Cycle electrical disconnect switch next to furnace on and off. Watch at least three ignition cycles. Pilot should ignite main burners smoothly.

12.Burner flames should look the same with circulation blower on and off.

13.Remove manometer from gas control and replace outlet pressure tap

14.Use a commercial soap solution made to detect leaks and check all gas piping connections. Bubbles indicate gas leakage. Seal all leaks before proceeding.

15.Replace burner access panel using three screws removed in step 2.

16.Set room thermostat to desired setting.

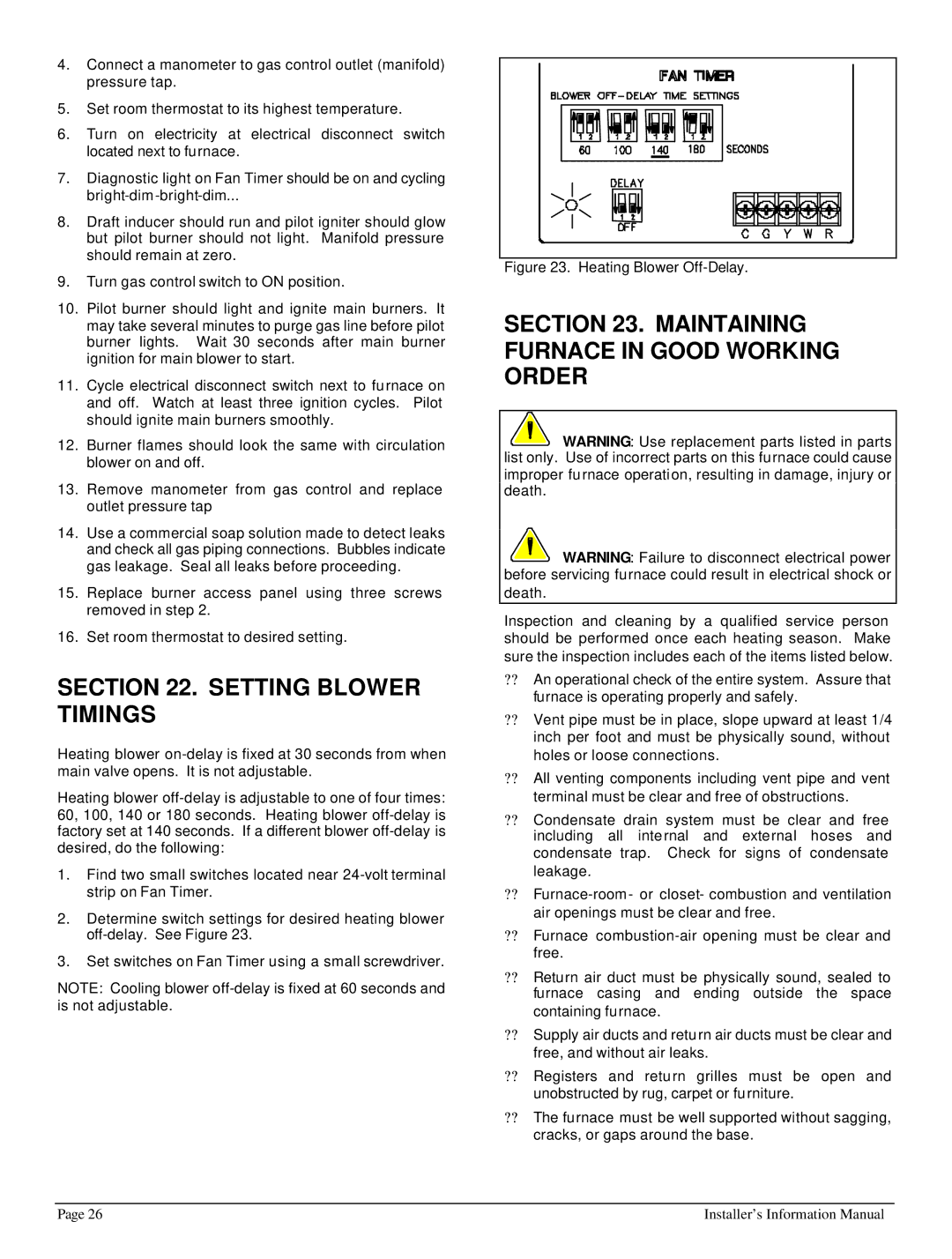

SECTION 22. SETTING BLOWER TIMINGS

Heating blower

Heating blower

1.Find two small switches located near

2.Determine switch settings for desired heating blower

3.Set switches on Fan Timer using a small screwdriver.

NOTE: Cooling blower

Figure 23. Heating Blower Off-Delay.

SECTION 23. MAINTAINING FURNACE IN GOOD WORKING ORDER

![]() WARNING: Use replacement parts listed in parts list only. Use of incorrect parts on this furnace could cause improper furnace operation, resulting in damage, injury or death.

WARNING: Use replacement parts listed in parts list only. Use of incorrect parts on this furnace could cause improper furnace operation, resulting in damage, injury or death.

![]() WARNING: Failure to disconnect electrical power before servicing furnace could result in electrical shock or death.

WARNING: Failure to disconnect electrical power before servicing furnace could result in electrical shock or death.

Inspection and cleaning by a qualified service person should be performed once each heating season. Make sure the inspection includes each of the items listed below.

??An operational check of the entire system. Assure that furnace is operating properly and safely.

??Vent pipe must be in place, slope upward at least 1/4 inch per foot and must be physically sound, without holes or loose connections.

??All venting components including vent pipe and vent terminal must be clear and free of obstructions.

??Condensate drain system must be clear and free including all internal and external hoses and condensate trap. Check for signs of condensate leakage.

??

??Furnace

??Return air duct must be physically sound, sealed to furnace casing and ending outside the space containing furnace.

??Supply air ducts and return air ducts must be clear and free, and without air leaks.

??Registers and return grilles must be open and unobstructed by rug, carpet or furniture.

??The furnace must be well supported without sagging, cracks, or gaps around the base.

Page 26 | Installer’s Information Manual |