Calculate the free area required.

Because combustion and ventilation air ducts run horizontally, allow 2,000 Btu per hour.

Furnace input (Btu/hr) | = | Free area required |

2,000 Btu/hr |

|

|

per square inch |

|

|

90,000 | = | 45 square inches |

2,000 |

|

|

Both of the ducts must have a minimum cross sectional area of 45 square inches.

SECTION 5. CONDENSATE DRAIN

This furnace produces water as a product of combustion. Much of this water condenses on the stainless steel tubing of the heat exchanger and in the vent system. This water (referred ot as condensate) must be drained from the furnace into a household drain. The following notes should be considered when connecting condensate drain:

??The furnace’s drain trap must be primed. This is easily done by pouring a few cups of water into furnace vent pipe after drain installation is complete.

??A frozen or blocked drain line will cause furnace shutdown and

??When a condensate pump is used, select a pump designed for furnace condensate.

SECTION 6. INSTALLING GAS PIPING

PREPARATION

Refer to the current National Fuel Gas Code ANSI Z223.1/NFPA 54 or CAN/CGA B149 Installation Codes and local codes for gas piping requirements and sizing. Pipe size running to furnace depends on:

??Length of pipe

??Number of fittings

??Specific gravity of gas

??Input requirements (Btu per hour) of all gas

Plan furnace gas supply piping so it will not interfere with removal of burner assembly, front door or blower door for servicing.

Make sure gas piping is large enough for all appliances connected to it to operate at once without lowering gas supply pressure. Failure to do so could cause lighting or burning problems on any of the appliances.

Always use a pipe thread compound that is resistant to propane (LP) gas solvent action. Sparingly apply thread

compound to all joints on male threads only, starting two threads from the end.

INSTALLATION

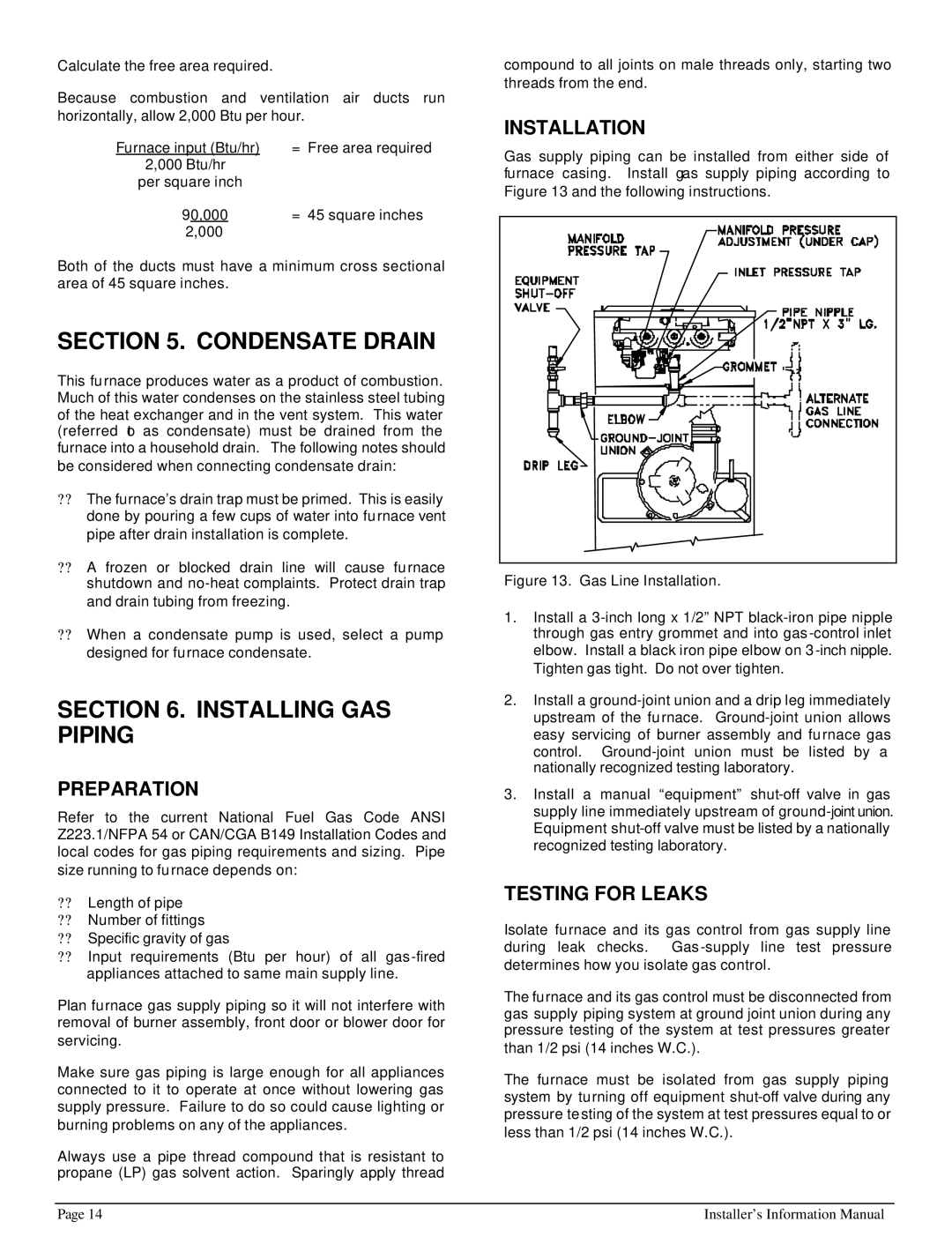

Gas supply piping can be installed from either side of furnace casing. Install gas supply piping according to Figure 13 and the following instructions.

Figure 13. Gas Line Installation.

1.Install a 3-inch long x 1/2” NPT black-iron pipe nipple through gas entry grommet and into gas -control inlet elbow. Install a black iron pipe elbow on 3 -inch nipple. Tighten gas tight. Do not over tighten.

2.Install a ground-joint union and a drip leg immediately upstream of the furnace. Ground-joint union allows easy servicing of burner assembly and furnace gas control. Ground-joint union must be listed by a nationally recognized testing laboratory.

3.Install a manual “equipment” shut-off valve in gas supply line immediately upstream of ground-joint union. Equipment shut-off valve must be listed by a nationally recognized testing laboratory.

TESTING FOR LEAKS

Isolate furnace and its gas control from gas supply line during leak checks. Gas

The furnace and its gas control must be disconnected from gas supply piping system at ground joint union during any pressure testing of the system at test pressures greater than 1/2 psi (14 inches W.C.).

The furnace must be isolated from gas supply piping system by turning off equipment

Page 14 | Installer’s Information Manual |