DIRECT-VENT TERMINATION

You may terminate vent and combustion air pipes either vertically (through the roof) or horizontally (through a side wall). Vertical (through the roof) venting is preferred because it offers protection from pipe damage and condensate damage. You may use concentric vent termination except on 126,000 BTU input furnaces. Follow the instructions supplied with the

For vertical direct venting, combustion air inlet pipe must terminate next to vent pipe and 12 inches above roof (18” in Canada) or highest expected snow accumulation. Extend vent pipe at least 6 inches above combustion air inlet. See Figure 4a for vertical direct vent termination.

Figure 4a. Vertical Termination for Direct Venting.

Combus tion-air-inlet termination must always be pointed downward to keep out rain and snow. Furnace will not operate properly with water in combustion compartment.

Note: When properly installed, vent pipe is designed to drain condensate and will not be affected by rainwater.

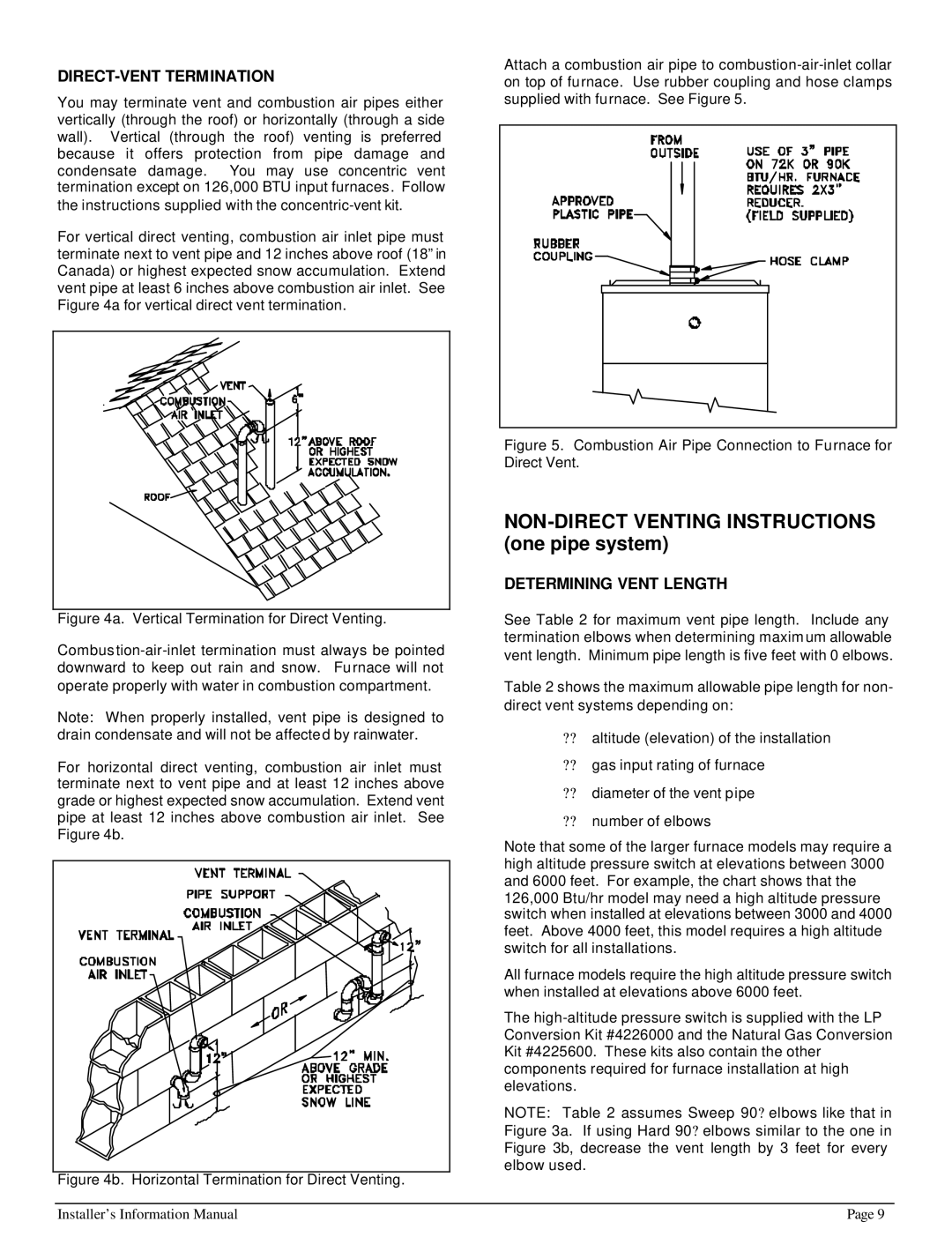

For horizontal direct venting, combustion air inlet must terminate next to vent pipe and at least 12 inches above grade or highest expected snow accumulation. Extend vent pipe at least 12 inches above combustion air inlet. See Figure 4b.

Figure 4b. Horizontal Termination for Direct Venting.

Attach a combustion air pipe to combustion-air-inlet collar on top of furnace. Use rubber coupling and hose clamps supplied with furnace. See Figure 5.

Figure 5. Combustion Air Pipe Connection to Furnace for Direct Vent.

NON-DIRECT VENTING INSTRUCTIONS (one pipe system)

DETERMINING VENT LENGTH

See Table 2 for maximum vent pipe length. Include any termination elbows when determining maximum allowable vent length. Minimum pipe length is five feet with 0 elbows.

Table 2 shows the maximum allowable pipe length for non- direct vent systems depending on:

??altitude (elevation) of the installation

??gas input rating of furnace

??diameter of the vent pipe

??number of elbows

Note that some of the larger furnace models may require a high altitude pressure switch at elevations between 3000 and 6000 feet. For example, the chart shows that the 126,000 Btu/hr model may need a high altitude pressure switch when installed at elevations between 3000 and 4000 feet. Above 4000 feet, this model requires a high altitude switch for all installations.

All furnace models require the high altitude pressure switch when installed at elevations above 6000 feet.

The

NOTE: Table 2 assumes Sweep 90? elbows like that in Figure 3a. If using Hard 90? elbows similar to the one in Figure 3b, decrease the vent length by 3 feet for every elbow used.

Installer’s Information Manual | Page 9 |