Operating Instructions and Parts Manual | HVLP Gravity Feed Spray Gun |

Manual de Instrucciones y Lista de Piezas | Pistola Pulverizadora HVLP Alimentada por Gravedad |

Preparation (Cont.)

paint.

5.The fluid control knob can be used to finely adjust pattern consistency.

Before spraying the workpiece, practice a few minutes on a cardboard target to ensure the pattern size and consistency are set correctly.

Operation

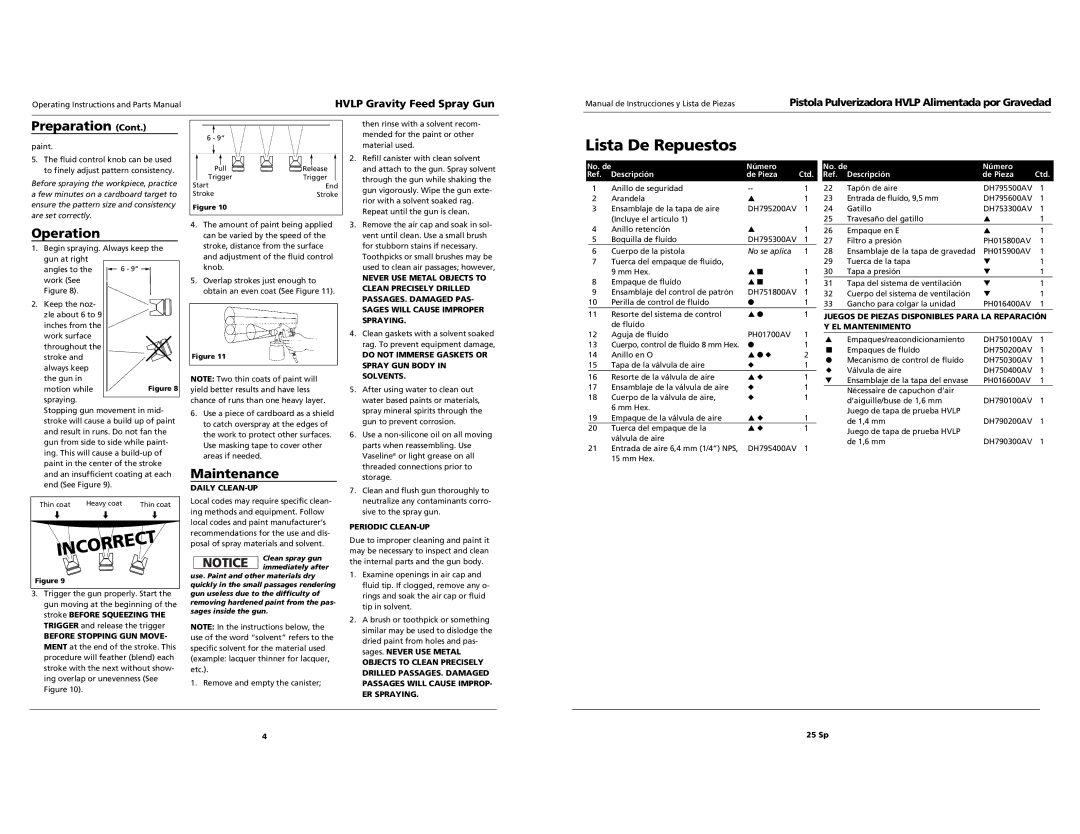

1.Begin spraying. Always keep the gun at right

angles to the work (See Figure 8).

2.Keep the noz- zle about 6 to 9 inches from the work surface throughout the stroke and always keep the gun in

motion while spraying.

Stopping gun movement in mid- stroke will cause a build up of paint and result in runs. Do not fan the gun from side to side while paint- ing. This will cause a

Thin coat | Heavy coat | Thin coat |

Figure 9

3.Trigger the gun properly. Start the gun moving at the beginning of the stroke BEFORE SQUEEZING THE TRIGGER and release the trigger

BEFORE STOPPING GUN MOVE- MENT at the end of the stroke. This procedure will feather (blend) each stroke with the next without show- ing overlap or unevenness (See Figure 10).

6 - 9” |

|

Pull | Release |

Trigger | Trigger |

Start | End |

Stroke | Stroke |

Figure 10 |

|

4.The amount of paint being applied can be varied by the speed of the stroke, distance from the surface and adjustment of the fluid control knob.

5.Overlap strokes just enough to obtain an even coat (See Figure 11).

Figure 11

NOTE: Two thin coats of paint will yield better results and have less chance of runs than one heavy layer.

6.Use a piece of cardboard as a shield to catch overspray at the edges of the work to protect other surfaces. Use masking tape to cover other areas if needed.

Maintenance

DAILY CLEAN-UP

Local codes may require specific clean- ing methods and equipment. Follow local codes and paint manufacturer’s recommendations for the use and dis- posal of spray materials and solvent.

Clean spray gun

NOTICE immediately after use. Paint and other materials dry quickly in the small passages rendering gun useless due to the difficulty of removing hardened paint from the pas- sages inside the gun.

NOTE: In the instructions below, the use of the word “solvent” refers to the specific solvent for the material used (example: lacquer thinner for lacquer, etc.).

1. Remove and empty the canister;

then rinse with a solvent recom- mended for the paint or other material used.

2.Refill canister with clean solvent and attach to the gun. Spray solvent through the gun while shaking the gun vigorously. Wipe the gun exte- rior with a solvent soaked rag. Repeat until the gun is clean.

3.Remove the air cap and soak in sol- vent until clean. Use a small brush for stubborn stains if necessary. Toothpicks or small brushes may be used to clean air passages; however,

NEVER USE METAL OBJECTS TO CLEAN PRECISELY DRILLED PASSAGES. DAMAGED PAS- SAGES WILL CAUSE IMPROPER SPRAYING.

4.Clean gaskets with a solvent soaked rag. To prevent equipment damage,

DO NOT IMMERSE GASKETS OR SPRAY GUN BODY IN SOLVENTS.

5.After using water to clean out water based paints or materials, spray mineral spirits through the gun to prevent corrosion.

6.Use a

7.Clean and flush gun thoroughly to neutralize any contaminants corro- sive to the spray gun.

PERIODIC CLEAN-UP

Due to improper cleaning and paint it may be necessary to inspect and clean the internal parts and the gun body.

1.Examine openings in air cap and fluid tip. If clogged, remove any o- rings and soak the air cap or fluid tip in solvent.

2.A brush or toothpick or something similar may be used to dislodge the dried paint from holes and pas- sages. NEVER USE METAL

OBJECTS TO CLEAN PRECISELY DRILLED PASSAGES. DAMAGED PASSAGES WILL CAUSE IMPROP- ER SPRAYING.

Lista De Repuestos

No. de | Número |

| ||

Ref. | Descripción | de Pieza | Ctd. | |

1 | Anillo de seguridad | 1 | ||

2 | Arandela | ▲ | 1 | |

3 | Ensamblaje de la tapa de aire | DH795200AV | 1 | |

|

| (Incluye el artículo 1) |

|

|

4 | Anillo retención | ▲ | 1 | |

| 5 | Boquilla de fluído | DH795300AV | 1 |

6 | Cuerpo de la pistola | No se aplica | 1 | |

7Tuerca del empaque de fluido,

| 9 mm Hex. | ▲ ■ | 1 |

8 | Empaque de fluído | ▲ ■ | 1 |

9 | Ensamblaje del control de patrón | DH751800AV | 1 |

10 | Perilla de control de fluído | ● | 1 |

11 | Resorte del sistema de control | ▲ ● | 1 |

| de fluído |

|

|

12 | Aguja de fluído | PH01700AV | 1 |

13 | Cuerpo, control de fluido 8 mm Hex. | ● | 1 |

14 | Anillo en O | ▲ ● ◆ | 2 |

15 | Tapa de la válvula de aire | ◆ | 1 |

16 | Resorte de la válvula de aire | ▲ ◆ | 1 |

17 | Ensamblaje de la válvula de aire | ◆ | 1 |

18 | Cuerpo de la válvula de aire, | ◆ | 1 |

| 6 mm Hex. |

|

|

19 | Empaque de la válvula de aire | ▲ ◆ | 1 |

20 | Tuerca del empaque de la | ▲ ◆ | 1 |

| válvula de aire |

|

|

21 | Entrada de aire 6,4 mm (1/4”) NPS, | DH795400AV | 1 |

| 15 mm Hex. |

|

|

No. de | Número |

| ||

Ref. | Descripción | de Pieza | Ctd. | |

|

|

|

|

|

22 | Tapón de aire | DH795500AV | 1 | |

23 | Entrada de fluído, 9,5 mm | DH795600AV | 1 | |

24 | Gatillo | DH753300AV | 1 | |

| 25 | Travesaño del gatillo | ▲ | 1 |

26 | Empaque en E | ▲ | 1 | |

27 | Filtro a presión | PH015800AV | 1 | |

28 | Ensamblaje de la tapa de gravedad | PH015900AV | 1 | |

29 | Tuerca de la tapa | ▼ | 1 | |

| 30 | Tapa a presión | ▼ | 1 |

31 | Tapa del sistema de ventilación | ▼ | 1 | |

32 | Cuerpo del sistema de ventilación | ▼ | 1 | |

33 | Gancho para colgar la unidad | PH016400AV | 1 | |

| JUEGOS DE PIEZAS DISPONIBLES PARA LA REPARACIÓN | |||

| Y EL MANTENIMENTO |

|

| |

| ▲ | Empaques/reacondicionamiento | DH750100AV | 1 |

| ■ | Empaques de fluído | DH750200AV | 1 |

| ● | Mecanismo de control de fluído | DH750300AV | 1 |

| ◆ | Válvula de aire | DH750400AV | 1 |

| ▼ | Ensamblaje de la tapa del envase | PH016600AV | 1 |

|

| Nécessaire de capuchon d’air |

|

|

|

| d’aiguille/buse de 1,6 mm | DH790100AV | 1 |

|

| Juego de tapa de prueba HVLP |

|

|

|

| de 1,4 mm | DH790200AV | 1 |

|

| Juego de tapa de prueba HVLP |

|

|

|

| de 1,6 mm | DH790300AV | 1 |

|

|

|

|

|

4 | 25 Sp |