Manual de Instrucciones y Lista de Piezas | Pistola Pulverizadora HVLP Alimentada por Gravedad |

Operating Instructions and Parts Manual | HVLP Gravity Feed Spray Gun |

Para ordenar repuestos, sírvase llamar al concesionario más cercano a su domicilio

Sírvase darnos la siguiente información: | Puede escribirnos a: | |

- | Número del modelo | Campbell Hausfeld |

- Número de Serie o código con fecha (de haberlo) | Attn: Parts Department | |

- | Descripción y número del repuesto según la lista de repuestos | 100 Production Drive |

|

| Harrison, OH 45030 U.S.A. |

Maintenance

(Continued)

3.Remove and check the fluid needle for excessive wear at the tip and straightness.

IMPORTANT: If the needle tip is worn more on one side than the other, either the needle is bent or the gun body has been dropped or knocked

5.Unscrew packing nuts and replace the packing ONLY if a leak will not stop when the nut is tightened (See Figure 5). Do not

6.

STORING

1. When not using spray gun, turn the |

fluid adjustment knob counter- |

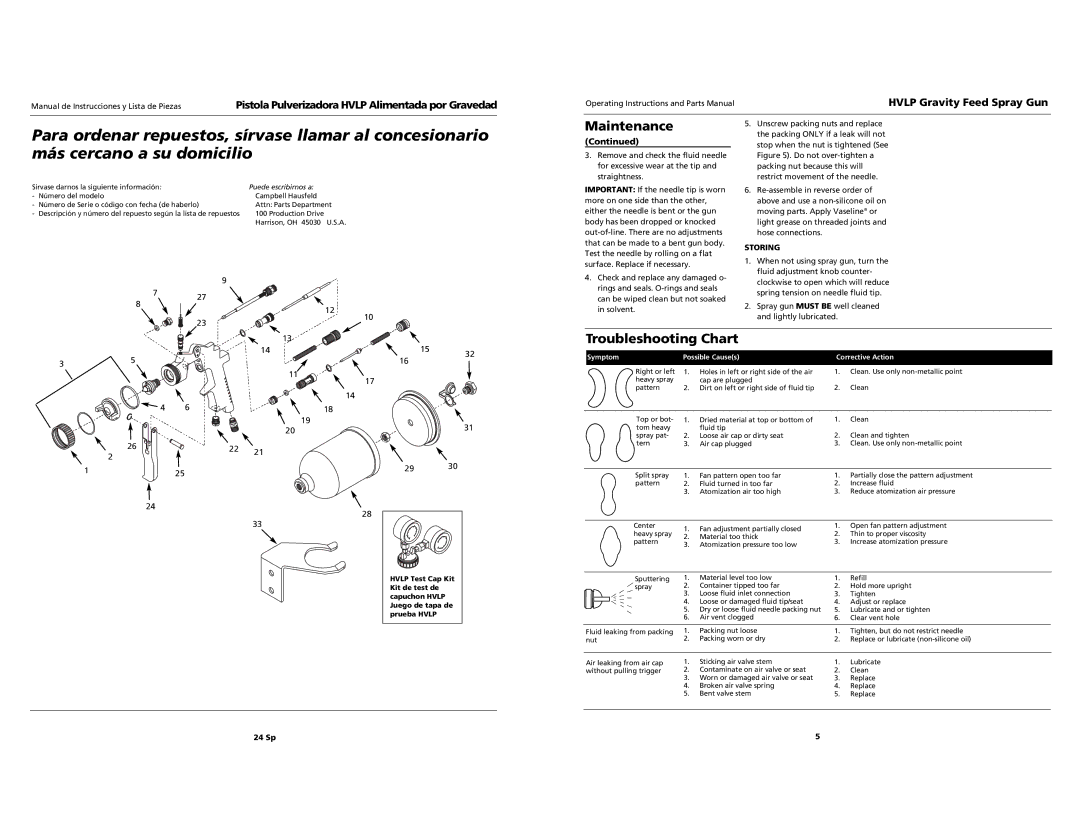

7

8

9

27

12

4.Check and replace any damaged o- rings and seals.

clockwise to open which will reduce |

spring tension on needle fluid tip. |

2. Spray gun MUST BE well cleaned |

23

10

and lightly lubricated. |

3![]() 5

5

![]() 4

4

![]() 13 14

13 14

11

17

14

6 | 18 |

19

15

16

32

Troubleshooting Chart

Symptom | Possible Cause(s) | Corrective Action | ||

Right or left | 1. | Holes in left or right side of the air | 1. | Clean. Use only |

heavy spray |

| cap are plugged |

|

|

pattern | 2. | Dirt on left or right side of fluid tip | 2. | Clean |

|

|

|

|

|

Top or bot- | 1. | Dried material at top or bottom of | 1. | Clean |

20

31

tom heavy | fluid tip |

|

spray pat- | 2. Loose air cap or dirty seat | 2. Clean and tighten |

| 26 | 22 | 21 |

2 |

| ||

|

| ||

|

|

|

125

24

28

33

29 30

HVLP Test Cap Kit Kit de test de capuchon HVLP Juego de tapa de prueba HVLP

|

|

|

|

| tern | 3. | Air cap plugged | 3. | Clean. Use only |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Split spray | 1. | Fan pattern open too far | 1. | Partially close the pattern adjustment |

|

|

|

|

| pattern | 2. | Fluid turned in too far | 2. | Increase fluid |

|

|

|

|

|

| 3. | Atomization air too high | 3. | Reduce atomization air pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Center | 1. | Fan adjustment partially closed | 1. | Open fan pattern adjustment |

|

|

|

|

| heavy spray | 2. | Thin to proper viscosity | ||

|

|

|

|

| 2. | Material too thick | |||

|

|

|

|

| pattern | 3. | Increase atomization pressure | ||

|

|

|

|

| 3. | Atomization pressure too low | |||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Sputtering | 1. | Material level too low | 1. | Refill |

|

|

|

|

| spray | 2. | Container tipped too far | 2. | Hold more upright |

|

|

|

|

|

| 3. | Loose fluid inlet connection | 3. | Tighten |

|

|

|

|

|

| 4. | Loose or damaged fluid tip/seat | 4. | Adjust or replace |

|

|

|

|

|

| 5. | Dry or loose fluid needle packing nut | 5. | Lubricate and or tighten |

|

|

|

|

|

| 6. | Air vent clogged | 6. | Clear vent hole |

|

|

|

|

|

| ||||

| Fluid leaking from packing | 1. | Packing nut loose | 1. | Tighten, but do not restrict needle | ||||

| nut | 2. | Packing worn or dry | 2. | Replace or lubricate | ||||

|

|

|

|

|

| ||||

| Air leaking from air cap | 1. | Sticking air valve stem | 1. | Lubricate | ||||

| without pulling trigger | 2. | Contaminate on air valve or seat | 2. | Clean | ||||

|

|

|

|

|

| 3. | Worn or damaged air valve or seat | 3. | Replace |

|

|

|

|

|

| 4. | Broken air valve spring | 4. | Replace |

|

|

|

|

|

| 5. | Bent valve stem | 5. | Replace |

|

|

|

|

|

|

|

|

|

|

24 Sp | 5 |