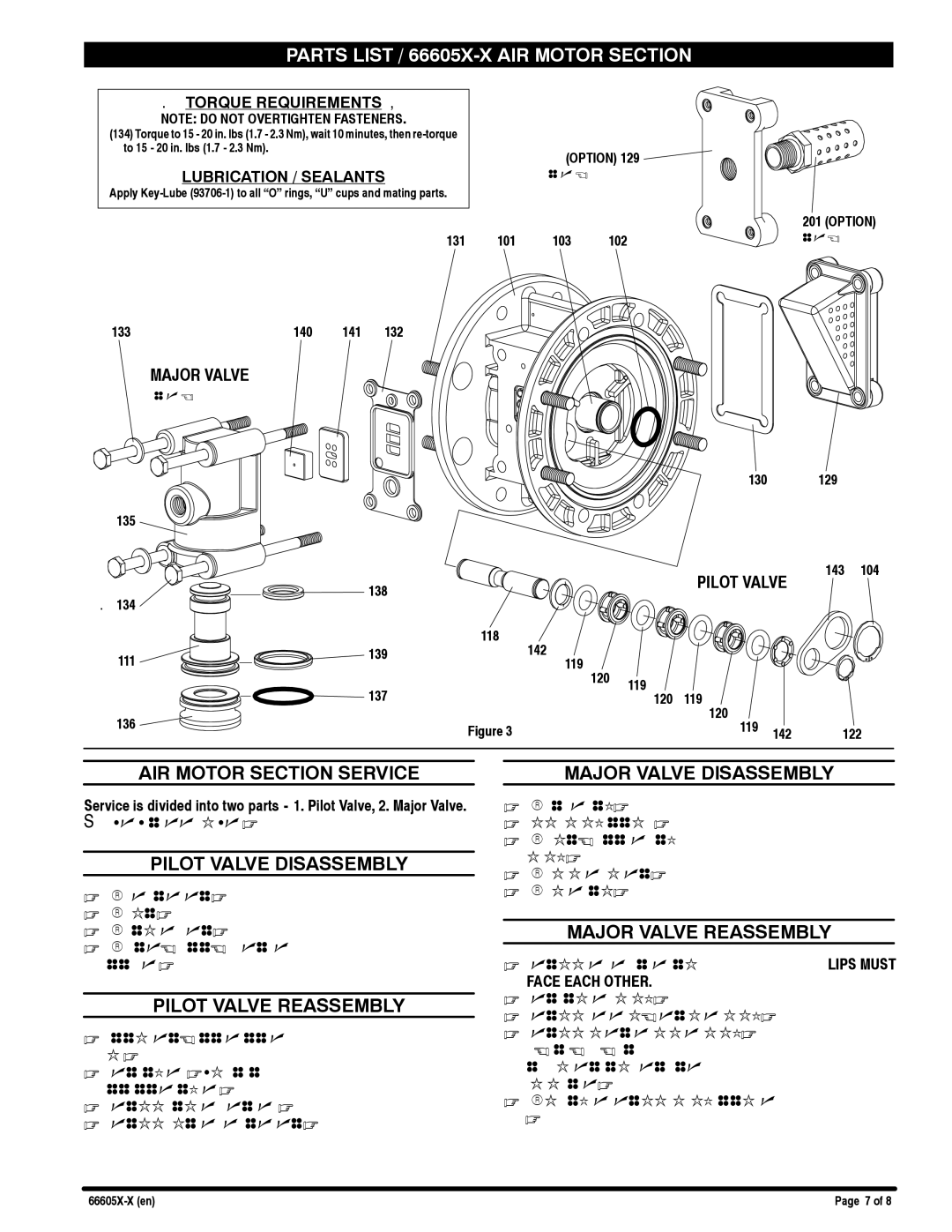

PARTS LIST /

. TORQUE REQUIREMENTS ,

NOTE: DO NOT OVERTIGHTEN FASTENERS.

(134)Torque to 15 - 20 in. lbs (1.7 - 2.3 Nm), wait 10 minutes, then

LUBRICATION / SEALANTS

Apply

131 101

133 | 140 | 141 | 132 |

MAJOR VALVE

(see note 3, page 6)

135

(OPTION) 129 ![]()

(see note 2, page 6)

201 (OPTION)

103 | 102 | (see note 2, page 6) |

130 129

138

. 134

118

111 | 139 |

| |

| 137 |

PILOT VALVE

142

119

120 119

120 119

120

143 104

136 | Figure 3 |

|

119 | 142 | 122 |

|

AIR MOTOR SECTION SERVICE

Service is divided into two parts - 1. Pilot Valve, 2. Major Valve.

SAir Motor Section Service is continued from Fluid Section repair.

PILOT VALVE DISASSEMBLY

1.Remove (122) and (104) snap rings.

2.Remove (143) plates.

3.Remove (103) sleeve and (102) “O” rings.

4.Remove (118) piston, (142) washers, (119) “O” rings and (120) spacers from (101) center body.

PILOT VALVE REASSEMBLY

1.Assemble (119) “O” rings, (120) spacers and (142) washers on (118) pilot rod.

2.Insert the stack into the (101) body. Sleeve (103) may be used to as- sist pressing stack into body.

3.Install (103) sleeve and (102) “O” rings into (101) body.

4.Install (143) plates and (122) and (104) snap rings.

MAJOR VALVE DISASSEMBLY

1.Remove (129) exhaust cover and (130) gasket.

2.Pull (135) valve block assembly from (101) body.

3.Remove (134) bolts, (133) washers and (132) gasket from (135) valve block.

4.Remove (141) valve plate and (140) valve insert.

5.Remove (136) plug and (111) spool.

MAJOR VALVE REASSEMBLY

1.Install new (139) and (138) “U” cups on (111) spool

FACE EACH OTHER.

2.Insert (111) spool into (135) valve block.

3.Install (137) “O” ring on (136) plug, insert plug into (135) valve block.

4.Install (140) valve insert and (141) valve plate into (135) valve block. Note: After 9/92, parts (140, 141) are white (ceramic), the dished side of the (140) valve insert should be against the shiny face of (141) valve plate for best performance.

5.Replace (132) gasket and install valve block assembly on (101) body.

Page 7 of 8 |