R

Reference Thermal SolutionReference Thermal SolutionReference Thermal Solution

6.5.4Thermal Interface Material

A thermal interface material provides improved conductivity between the die and heatsink. The reference thermal solution uses Chomerics*

Note: Unflowed or “dry” Chomerics* T710 has a material thickness of 0.005 inch. The flowed or “wet” Chromerics T710 has a material thickness of ~0.0025 inch after it reaches its phase change temperature.

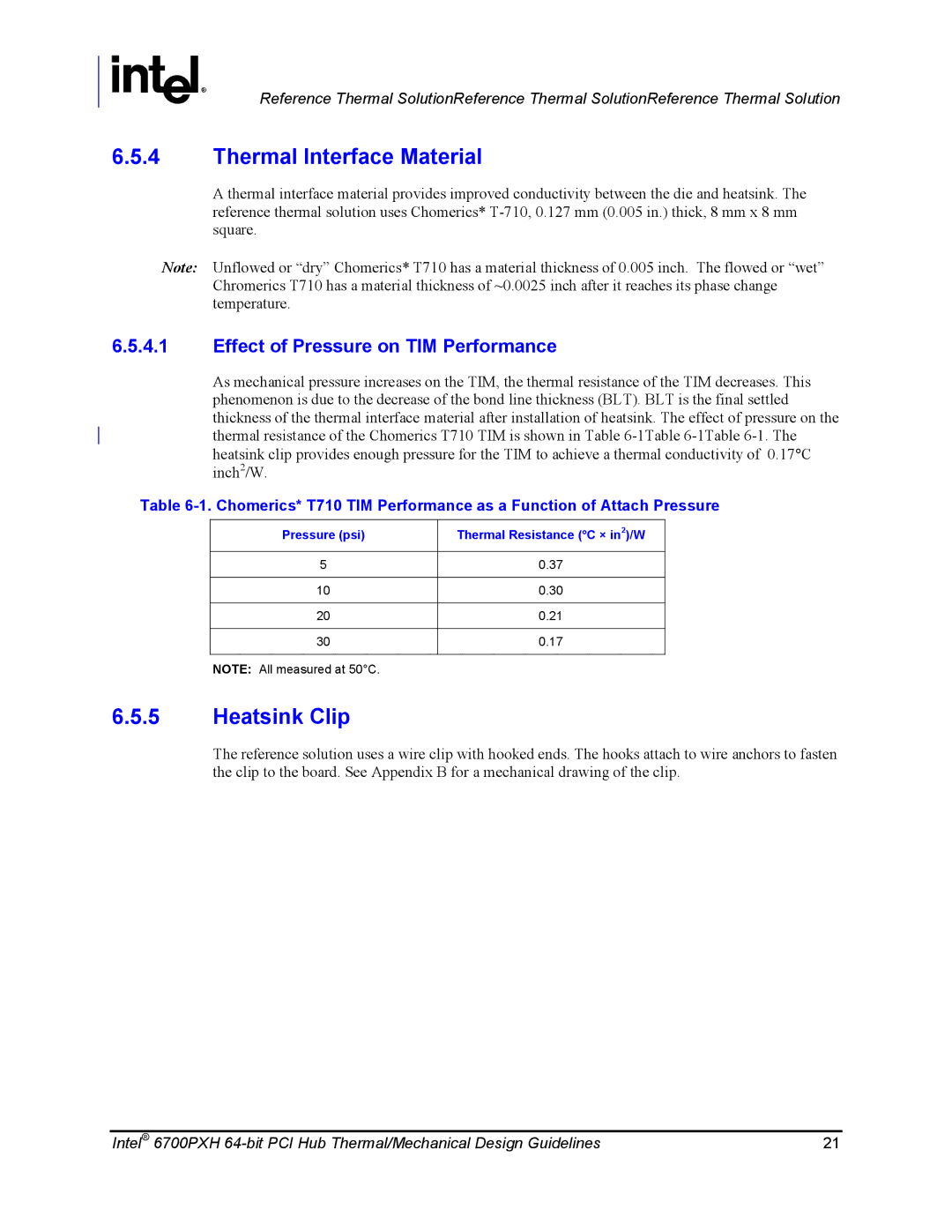

6.5.4.1Effect of Pressure on TIM Performance

As mechanical pressure increases on the TIM, the thermal resistance of the TIM decreases. This phenomenon is due to the decrease of the bond line thickness (BLT). BLT is the final settled thickness of the thermal interface material after installation of heatsink. The effect of pressure on the thermal resistance of the Chomerics T710 TIM is shown in Table

Table

Pressure (psi) | Thermal Resistance (°C × in2)/W |

|

|

5 | 0.37 |

|

|

10 | 0.30 |

|

|

20 | 0.21 |

|

|

30 | 0.17 |

|

|

NOTE: All measured at 50°C.

6.5.5Heatsink Clip

The reference solution uses a wire clip with hooked ends. The hooks attach to wire anchors to fasten the clip to the board. See Appendix B for a mechanical drawing of the clip.

Intel® 6700PXH | 21 |