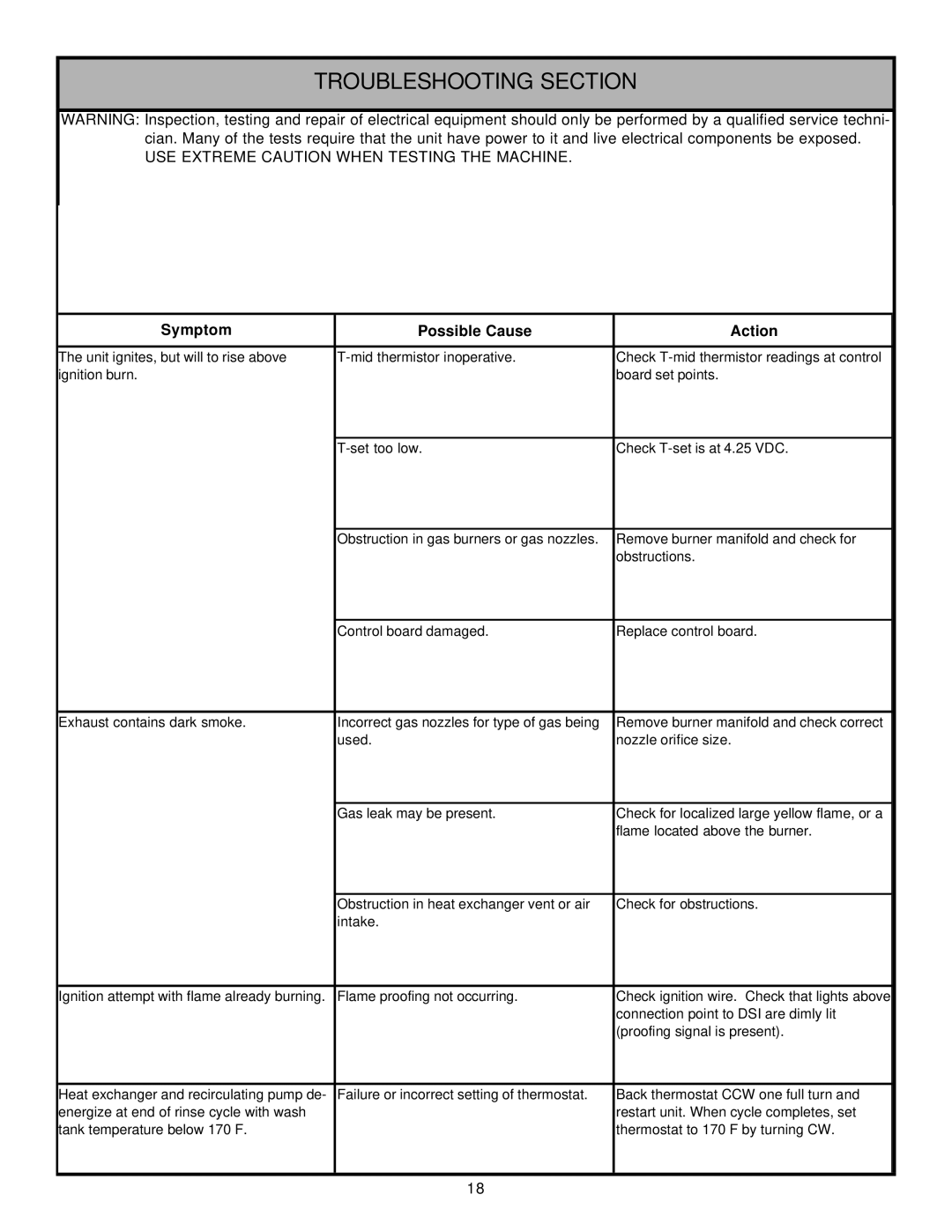

TROUBLESHOOTING SECTION

WARNING: Inspection, testing and repair of electrical equipment should only be performed by a qualified service techni- cian. Many of the tests require that the unit have power to it and live electrical components be exposed.

USE EXTREME CAUTION WHEN TESTING THE MACHINE.

|

|

|

|

|

| Symptom | Possible Cause | Action |

|

|

|

|

|

|

| The unit ignites, but will to rise above | Check |

| |

| ignition burn. |

| board set points. |

|

|

|

|

|

|

|

| Check |

| |

|

|

|

|

|

|

| Obstruction in gas burners or gas nozzles. | Remove burner manifold and check for |

|

|

|

| obstructions. |

|

|

|

|

|

|

|

| Control board damaged. | Replace control board. |

|

|

|

|

|

|

| Exhaust contains dark smoke. | Incorrect gas nozzles for type of gas being | Remove burner manifold and check correct |

|

|

| used. | nozzle orifice size. |

|

|

|

|

|

|

|

| Gas leak may be present. | Check for localized large yellow flame, or a |

|

|

|

| flame located above the burner. |

|

|

|

|

|

|

|

| Obstruction in heat exchanger vent or air | Check for obstructions. |

|

|

| intake. |

|

|

|

|

|

|

|

| Ignition attempt with flame already burning. | Flame proofing not occurring. | Check ignition wire. Check that lights above |

|

|

|

| connection point to DSI are dimly lit |

|

|

|

| (proofing signal is present). |

|

|

|

|

|

|

| Heat exchanger and recirculating pump de- | Failure or incorrect setting of thermostat. | Back thermostat CCW one full turn and |

|

| energize at end of rinse cycle with wash |

| restart unit. When cycle completes, set |

|

| tank temperature below 170 F. |

| thermostat to 170 F by turning CW. |

|

|

|

|

|

|

18