OVERVIEW OF OPERATION

PRESSURE

GAUGE

REGULATOR

RINSE ARM

CHECK VALVE

WASH TANK

WATER LEVEL

WL

PROBE

THERMOSTAT TS ![]()

![]()

WASH TANK

COILS ![]() T

T

WASH TEMP

RECIRCULATING

PUMP

VACUUM BREAKER

FILL / RINSE SOLENOID

T | RINSE TEMP | |

>180 F | ||

|

CHECK VALVE

BOOSTER

TANK

ECO

HEAT

EXCHANGER

BURNER

ASSEMBLY

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODULATING | COMBINATION GAS | |||||||||||

|

| VALVE | CUTOFF VALVE | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

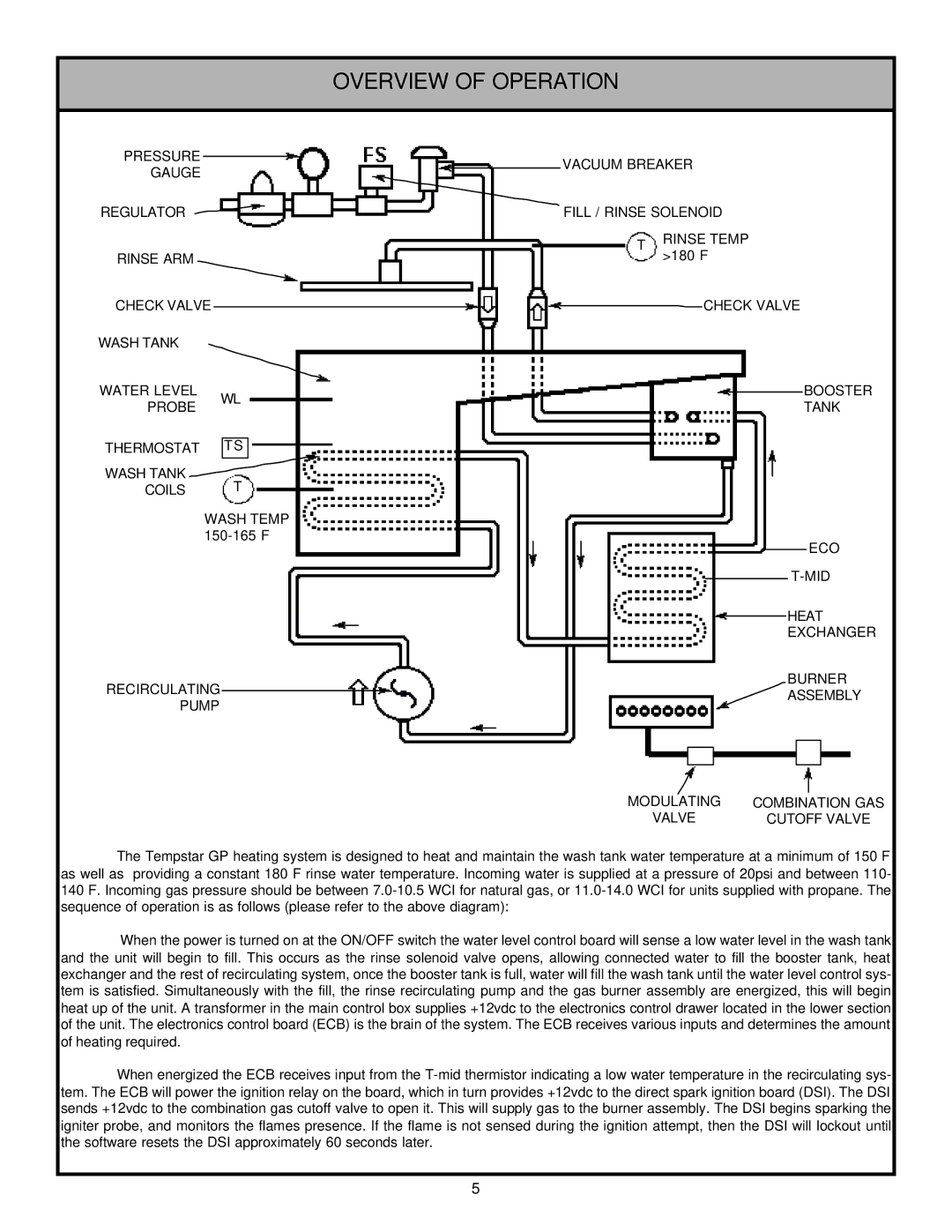

The Tempstar GP heating system is designed to heat and maintain the wash tank water temperature at a minimum of 150 F as well as providing a constant 180 F rinse water temperature. Incoming water is supplied at a pressure of 20psi and between 110- 140 F. Incoming gas pressure should be between

When the power is turned on at the ON/OFF switch the water level control board will sense a low water level in the wash tank and the unit will begin to fill. This occurs as the rinse solenoid valve opens, allowing connected water to fill the booster tank, heat exchanger and the rest of recirculating system, once the booster tank is full, water will fill the wash tank until the water level control sys- tem is satisfied. Simultaneously with the fill, the rinse recirculating pump and the gas burner assembly are energized, this will begin heat up of the unit. A transformer in the main control box supplies +12vdc to the electronics control drawer located in the lower section of the unit. The electronics control board (ECB) is the brain of the system. The ECB receives various inputs and determines the amount of heating required.

When energized the ECB receives input from the

5