JMS-12SCMS specifications

The Jet Tools JMS-12SCMS is a standout in the world of sliding compound miter saws, designed specifically for professionals and serious hobbyists alike. This sophisticated tool combines power, precision, and versatility, making it an essential addition to any workshop.At the heart of the JMS-12SCMS is its robust motor, which delivers an impressive 15 amps of power. This strength allows it to handle a wide variety of materials, from hardwoods to softer composites, making it ideal for intricate cuts and heavy-duty applications. With a maximum cutting capacity of 12 inches, the JMS-12SCMS can effortlessly slice through larger workpieces with ease, providing the kind of versatility that woodworkers crave.

One of the primary features of the jet saw is its innovative sliding mechanism. This sliding arm design allows for expanded cutting capacity, so users can achieve precise crosscuts and bevels without the need for additional tools. The smooth glide feature ensures that the saw moves effortlessly along its track, significantly reducing friction and wear.

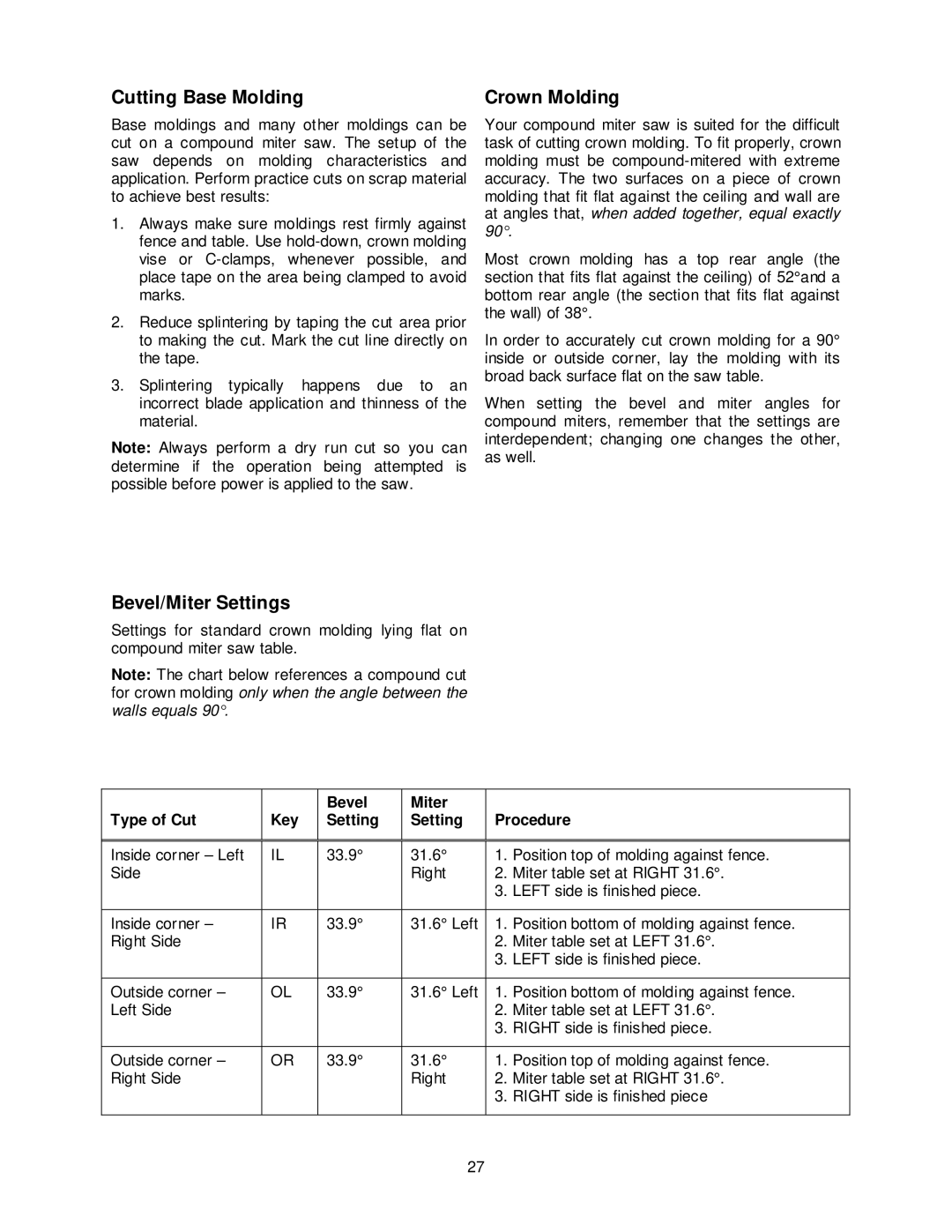

The JMS-12SCMS also boasts a dual bevel capability, allowing for bevel cuts up to 45 degrees left and right. This feature is particularly useful for complex projects that require intricate angles, giving users the flexibility to make precise adjustments without having to flip the workpiece. Additionally, the miter angle can be adjusted to a range of 60 degrees to the right and 52 degrees to the left, providing a comprehensive cutting range for any project.

For enhanced accuracy, this tool includes an easy-to-read digital display for miter and bevel angles, allowing users to set their cuts with confidence. The built-in laser guide further aids in precision, ensuring that every cut is exactly where it's needed.

Safety is always a priority, and the JMS-12SCMS incorporates several features to keep users protected. The saw’s blade guard effectively shields users from accidental contact with the blade, while the electric brake stops the blade quickly after the trigger is released, minimizing the risk of injury.

In conclusion, the Jet Tools JMS-12SCMS is an exceptional tool that combines robust power, innovative features, and a focus on safety. Its advanced technologies and user-friendly design make it a top choice for those seeking reliability and precision in their woodworking projects. Whether you're a professional contractor or a dedicated DIY enthusiast, the JMS-12SCMS will undoubtedly exceed your expectations.