90º Table Stop

Referring to Figure 4:

1.Slighty loosen the lock knob (C4) and tilt the table (C) up as shown.

2.Thread the M6 hex nut (T) approximately half way onto the M6x32 hex cap screw (O). Then thread the screw half way into the threaded mounting hole (C5) underneath the table. Adjustment will be made later.

Rail Guide and Fence

Installation

1.Attach the rail guide (F, Fig. 5) to the front of the table (C). Secure with four lock knobs (M).

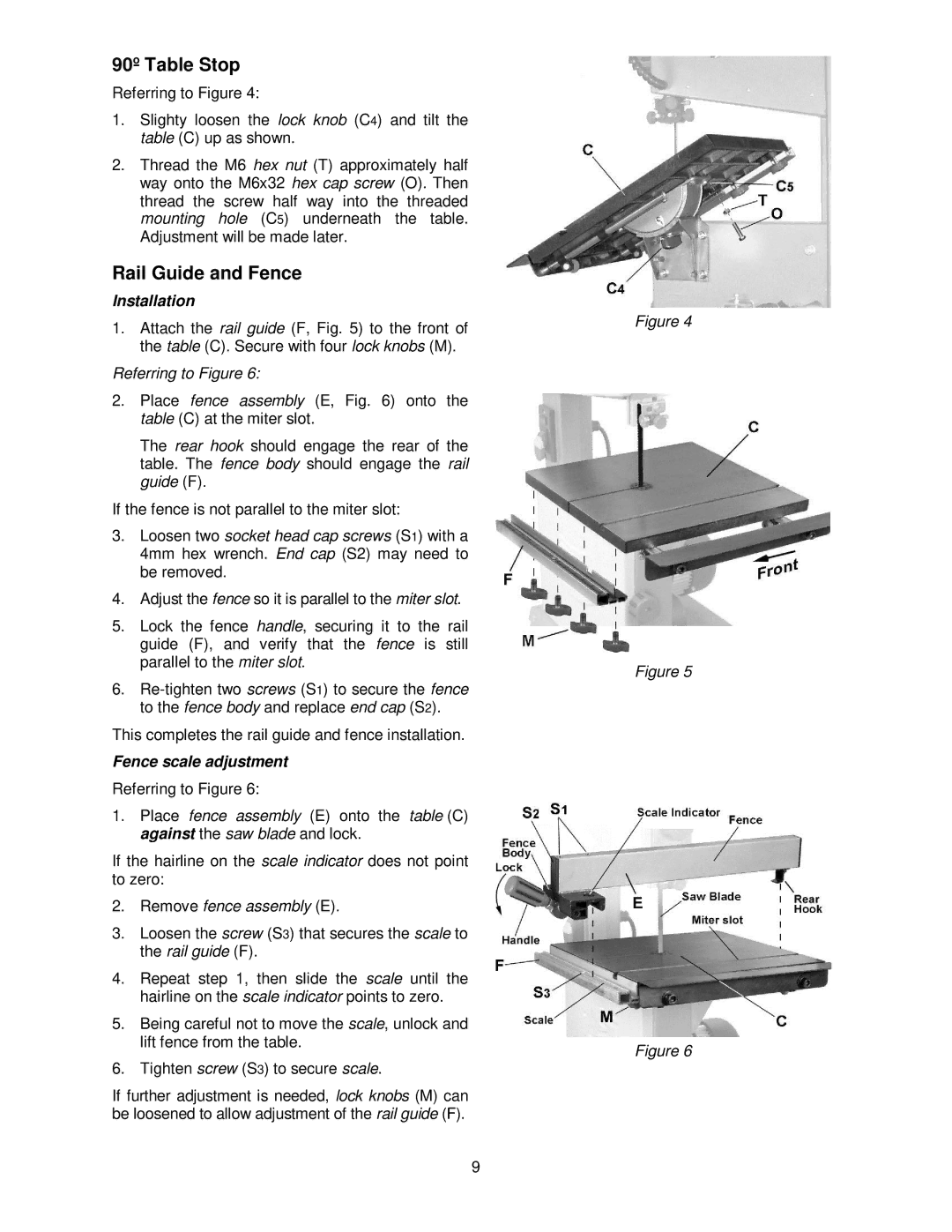

Referring to Figure 6:

2.Place fence assembly (E, Fig. 6) onto the table (C) at the miter slot.

The rear hook should engage the rear of the table. The fence body should engage the rail guide (F).

If the fence is not parallel to the miter slot:

3.Loosen two socket head cap screws (S1) with a 4mm hex wrench. End cap (S2) may need to be removed.

4.Adjust the fence so it is parallel to the miter slot.

5.Lock the fence handle, securing it to the rail guide (F), and verify that the fence is still parallel to the miter slot.

6.

This completes the rail guide and fence installation.

Fence scale adjustment

Referring to Figure 6:

1.Place fence assembly (E) onto the table (C) against the saw blade and lock.

If the hairline on the scale indicator does not point to zero:

2.Remove fence assembly (E).

3.Loosen the screw (S3) that secures the scale to the rail guide (F).

4.Repeat step 1, then slide the scale until the hairline on the scale indicator points to zero.

5.Being careful not to move the scale, unlock and lift fence from the table.

6.Tighten screw (S3) to secure scale.

If further adjustment is needed, lock knobs (M) can be loosened to allow adjustment of the rail guide (F).

Figure 4

Figure 5

Figure 6

9