Miter Gauge for Left Extension Wing

Hardware: Miter Gauge

Tools: Cross Point Screw Driver, Square

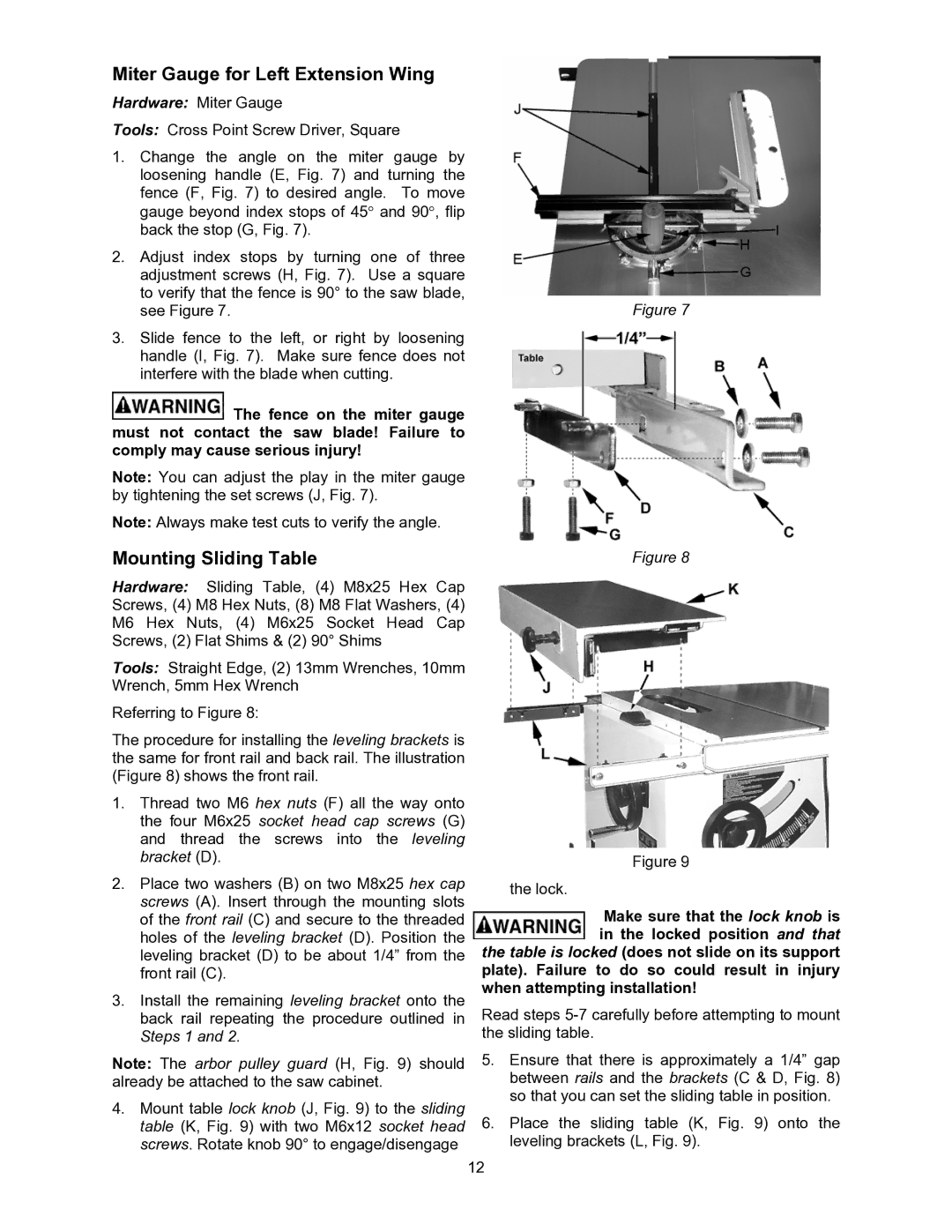

1.Change the angle on the miter gauge by loosening handle (E, Fig. 7) and turning the fence (F, Fig. 7) to desired angle. To move gauge beyond index stops of 45° and 90°, flip back the stop (G, Fig. 7).

2.Adjust index stops by turning one of three adjustment screws (H, Fig. 7). Use a square to verify that the fence is 90° to the saw blade, see Figure 7.

3.Slide fence to the left, or right by loosening handle (I, Fig. 7). Make sure fence does not interfere with the blade when cutting.

![]() The fence on the miter gauge must not contact the saw blade! Failure to comply may cause serious injury!

The fence on the miter gauge must not contact the saw blade! Failure to comply may cause serious injury!

Note: You can adjust the play in the miter gauge by tightening the set screws (J, Fig. 7).

Note: Always make test cuts to verify the angle.

Mounting Sliding Table

Hardware: Sliding Table, (4) M8x25 Hex Cap Screws, (4) M8 Hex Nuts, (8) M8 Flat Washers, (4) M6 Hex Nuts, (4) M6x25 Socket Head Cap Screws, (2) Flat Shims & (2) 90° Shims

Tools: Straight Edge, (2) 13mm Wrenches, 10mm Wrench, 5mm Hex Wrench

Referring to Figure 8:

The procedure for installing the leveling brackets is the same for front rail and back rail. The illustration (Figure 8) shows the front rail.

1.Thread two M6 hex nuts (F) all the way onto the four M6x25 socket head cap screws (G) and thread the screws into the leveling bracket (D).

2.Place two washers (B) on two M8x25 hex cap screws (A). Insert through the mounting slots of the front rail (C) and secure to the threaded holes of the leveling bracket (D). Position the leveling bracket (D) to be about 1/4” from the front rail (C).

3.Install the remaining leveling bracket onto the back rail repeating the procedure outlined in Steps 1 and 2.

Note: The arbor pulley guard (H, Fig. 9) should already be attached to the saw cabinet.

4.Mount table lock knob (J, Fig. 9) to the sliding table (K, Fig. 9) with two M6x12 socket head screws. Rotate knob 90° to engage/disengage

Figure 7

Figure 8

Figure 9

the lock.

Make sure that the lock knob is in the locked position and that the table is locked (does not slide on its support

plate). Failure to do so could result in injury when attempting installation!

Read steps

5.Ensure that there is approximately a 1/4” gap between rails and the brackets (C & D, Fig. 8) so that you can set the sliding table in position.

6.Place the sliding table (K, Fig. 9) onto the leveling brackets (L, Fig. 9).

12