2.2 Cutter specification

Item | Parameters | Remark |

Cut method | Sliding blade |

|

|

|

|

Cut time | 600ms | Time for one cutter action |

|

|

|

Cut interval | 2s | 30 cuts/minutes (Max.) |

|

|

|

Adapt Paper | 65~100μm | Normal paper with same thickness |

|

|

|

Operation voltage | 24VDC |

|

|

|

|

Max. repose current | 1.2A | 24VDC |

|

|

|

Cutter lifetime | 1,000,000cuts | Under standard test conditions |

|

|

|

2.3 Paper Specification

2.3.1Continuous paper 1)Normal paper

¾Paper width: 80±0.5mm/76±0.5mm/69.5±0.5mm/57.5±0.5mm

¾Max. paper roll O/D: Φ83mm

¾Paper roll core: ID Φ12.5mm; OD Φ16mm

¾Paper thickness:

¾Paper width: 80±0.5mm/76±0.5mm/69.5±0.5mm/57.5±0.5mm

¾Paper thickness:

![]() Caution:

Caution:

Use only

2.3.2 Marked paper

Besides the requirements of the continuous paper, marked paper should follow the following requirements:

1)Mark place

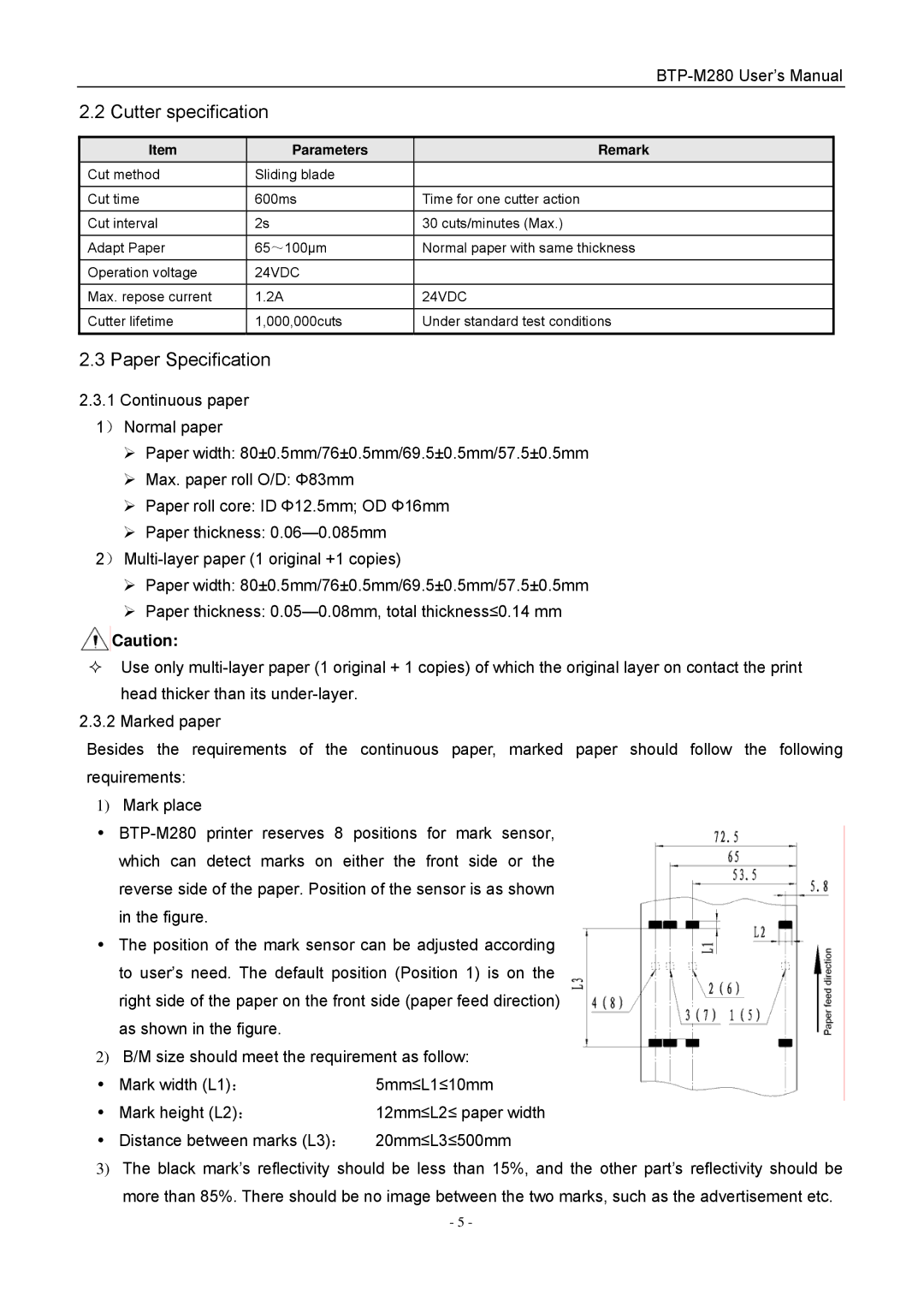

y

yThe position of the mark sensor can be adjusted according to user’s need. The default position (Position 1) is on the right side of the paper on the front side (paper feed direction) as shown in the figure.

2)B/M size should meet the requirement as follow:

y | Mark width (L1): | 5mm≤L1≤10mm |

y | Mark height (L2): | 12mm≤L2≤ paper width |

y Distance between marks (L3): | 20mm≤L3≤500mm | |

3)The black mark’s reflectivity should be less than 15%, and the other part’s reflectivity should be more than 85%. There should be no image between the two marks, such as the advertisement etc.

- 5 -