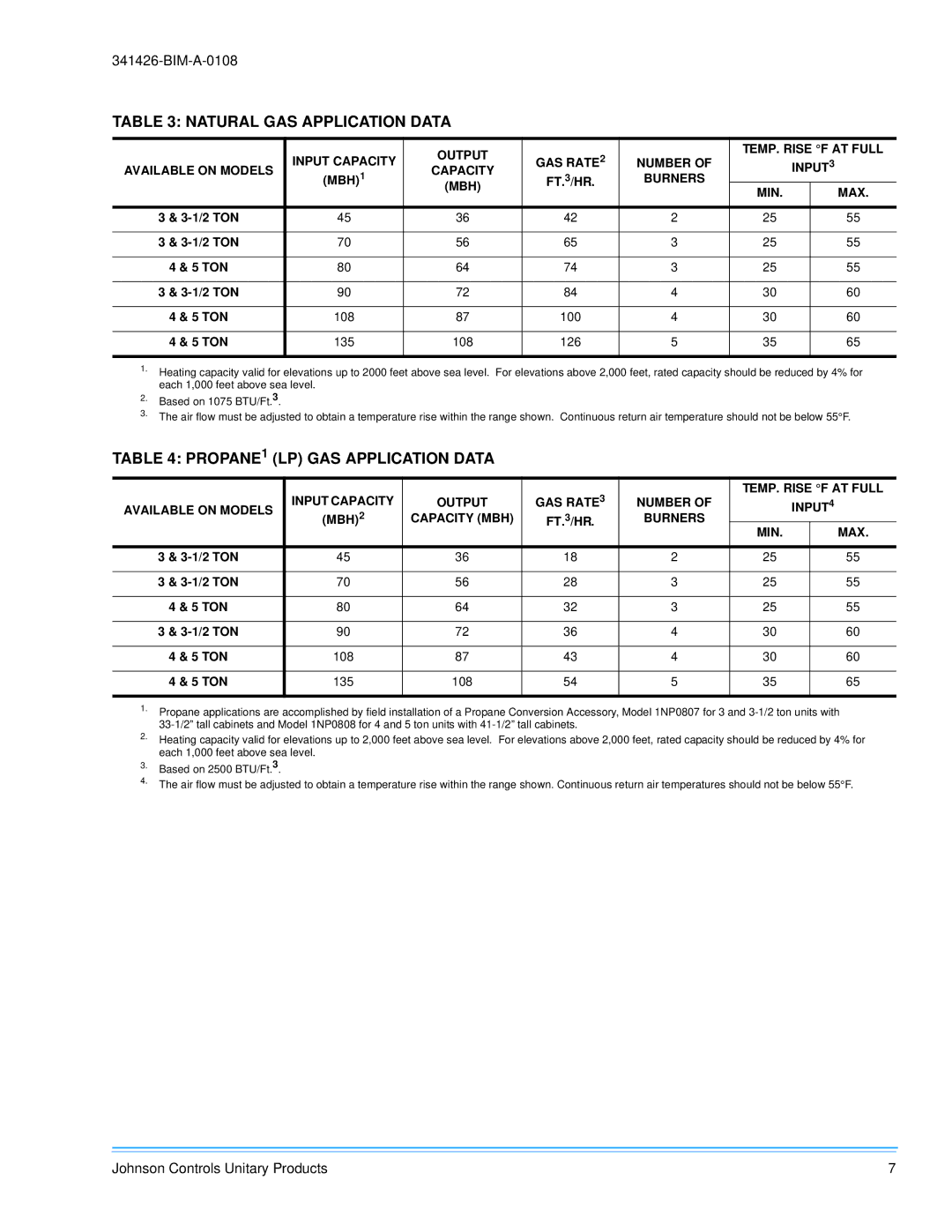

TABLE 3: NATURAL GAS APPLICATION DATA

| INPUT CAPACITY | OUTPUT | GAS RATE | 2 | NUMBER OF | TEMP. RISE °F AT FULL | ||

|

| INPUT3 | ||||||

AVAILABLE ON MODELS | CAPACITY |

| ||||||

(MBH)1 |

|

| ||||||

| (MBH) | FT.3/HR. |

| BURNERS |

|

|

| |

|

| MIN. |

| MAX. | ||||

|

|

|

|

|

| |||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

3 & | 45 | 36 | 42 |

| 2 | 25 |

| 55 |

|

|

|

|

|

|

|

|

|

3 & | 70 | 56 | 65 |

| 3 | 25 |

| 55 |

|

|

|

|

|

|

|

|

|

4 & 5 TON | 80 | 64 | 74 |

| 3 | 25 |

| 55 |

|

|

|

|

|

|

|

|

|

3 & | 90 | 72 | 84 |

| 4 | 30 |

| 60 |

|

|

|

|

|

|

|

|

|

4 & 5 TON | 108 | 87 | 100 |

| 4 | 30 |

| 60 |

|

|

|

|

|

|

|

|

|

4 & 5 TON | 135 | 108 | 126 |

| 5 | 35 |

| 65 |

|

|

|

|

|

|

|

|

|

1.Heating capacity valid for elevations up to 2000 feet above sea level. For elevations above 2,000 feet, rated capacity should be reduced by 4% for each 1,000 feet above sea level.

2.Based on 1075 BTU/Ft.3.

3.The air flow must be adjusted to obtain a temperature rise within the range shown. Continuous return air temperature should not be below 55°F.

TABLE 4: PROPANE1 (LP) GAS APPLICATION DATA

| INPUT CAPACITY | OUTPUT | GAS RATE | 3 | NUMBER OF | TEMP. RISE °F AT FULL | ||

AVAILABLE ON MODELS |

| INPUT4 | ||||||

(MBH)2 |

|

| ||||||

| CAPACITY (MBH) | FT.3/HR. |

| BURNERS |

|

|

| |

|

| MIN. |

| MAX. | ||||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

3 & | 45 | 36 | 18 |

| 2 | 25 |

| 55 |

|

|

|

|

|

|

|

|

|

3 & | 70 | 56 | 28 |

| 3 | 25 |

| 55 |

|

|

|

|

|

|

|

|

|

4 & 5 TON | 80 | 64 | 32 |

| 3 | 25 |

| 55 |

|

|

|

|

|

|

|

|

|

3 & | 90 | 72 | 36 |

| 4 | 30 |

| 60 |

|

|

|

|

|

|

|

|

|

4 & 5 TON | 108 | 87 | 43 |

| 4 | 30 |

| 60 |

|

|

|

|

|

|

|

|

|

4 & 5 TON | 135 | 108 | 54 |

| 5 | 35 |

| 65 |

|

|

|

|

|

|

|

|

|

1.Propane applications are accomplished by field installation of a Propane Conversion Accessory, Model 1NP0807 for 3 and

2.Heating capacity valid for elevations up to 2,000 feet above sea level. For elevations above 2,000 feet, rated capacity should be reduced by 4% for each 1,000 feet above sea level.

3.Based on 2500 BTU/Ft.3.

4.The air flow must be adjusted to obtain a temperature rise within the range shown. Continuous return air temperatures should not be below 55°F.

Johnson Controls Unitary Products | 7 |