INSTALLATION

LIMITATIONS

These units must be installed in accordance with the follow- ing national and local safety codes.

1.National Electrical Code ANSI/NFPS No. 70 or Canadian Electrical Code Part 1, C22.1 (latest editions).

2.National Fuel Gas Code Z223.1 or CAN/CGA B149.1 or.2 Installation Code.

3.Local gas utility requirements.

4.Local plumbing and waste water codes and other appli- cable local codes.

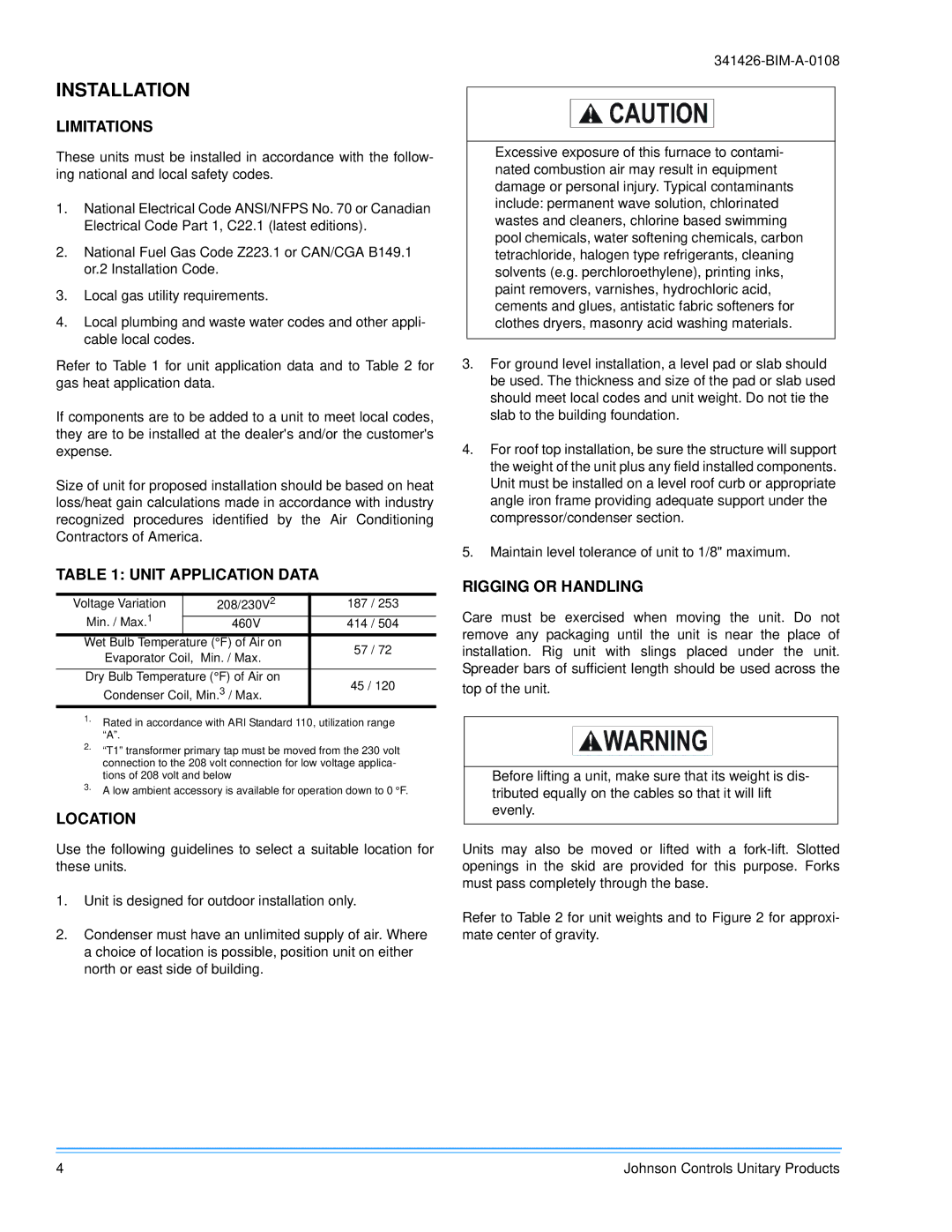

Refer to Table 1 for unit application data and to Table 2 for gas heat application data.

If components are to be added to a unit to meet local codes, they are to be installed at the dealer's and/or the customer's expense.

Size of unit for proposed installation should be based on heat loss/heat gain calculations made in accordance with industry recognized procedures identified by the Air Conditioning Contractors of America.

TABLE 1: UNIT APPLICATION DATA

Voltage Variation |

| 208/230V2 | 187 | / 253 | |

Min. / Max.1 |

|

|

|

| |

| 460V | 414 | / 504 | ||

Wet Bulb Temperature (°F) of Air on | 57 | / 72 | |||

Evaporator Coil, | Min. / Max. | ||||

|

| ||||

|

|

| |||

Dry Bulb Temperature (°F) of Air on | 45 / 120 | ||||

Condenser Coil, Min.3 / Max. | |||||

|

| ||||

1.Rated in accordance with ARI Standard 110, utilization range “A”.

2.“T1” transformer primary tap must be moved from the 230 volt connection to the 208 volt connection for low voltage applica- tions of 208 volt and below

3.A low ambient accessory is available for operation down to 0 °F.

LOCATION

Use the following guidelines to select a suitable location for these units.

1.Unit is designed for outdoor installation only.

2.Condenser must have an unlimited supply of air. Where a choice of location is possible, position unit on either north or east side of building.

Excessive exposure of this furnace to contami- nated combustion air may result in equipment damage or personal injury. Typical contaminants include: permanent wave solution, chlorinated wastes and cleaners, chlorine based swimming pool chemicals, water softening chemicals, carbon tetrachloride, halogen type refrigerants, cleaning solvents (e.g. perchloroethylene), printing inks, paint removers, varnishes, hydrochloric acid, cements and glues, antistatic fabric softeners for clothes dryers, masonry acid washing materials.

3.For ground level installation, a level pad or slab should be used. The thickness and size of the pad or slab used should meet local codes and unit weight. Do not tie the slab to the building foundation.

4.For roof top installation, be sure the structure will support the weight of the unit plus any field installed components. Unit must be installed on a level roof curb or appropriate angle iron frame providing adequate support under the compressor/condenser section.

5.Maintain level tolerance of unit to 1/8" maximum.

RIGGING OR HANDLING

Care must be exercised when moving the unit. Do not remove any packaging until the unit is near the place of installation. Rig unit with slings placed under the unit. Spreader bars of sufficient length should be used across the

top of the unit.

Before lifting a unit, make sure that its weight is dis- tributed equally on the cables so that it will lift evenly.

Units may also be moved or lifted with a

Refer to Table 2 for unit weights and to Figure 2 for approxi- mate center of gravity.

4 | Johnson Controls Unitary Products |