4-wire connection: Direct Wire

IMPORTANT: A

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer can be moved if needed.

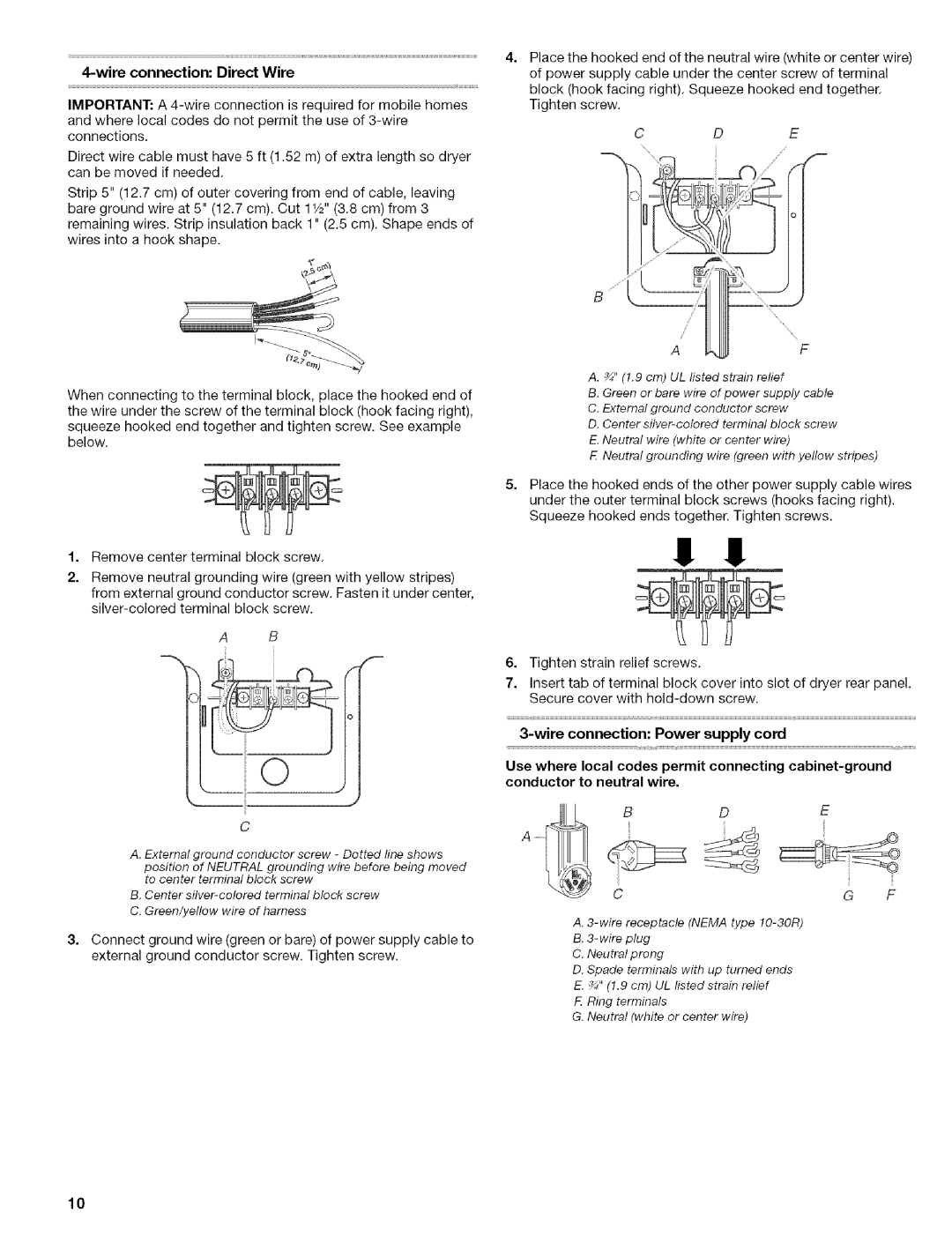

Strip 5" (12.7 cm) of outer covering from end of cable, leaving bare ground wire at 5" (12.7 cm). Cut 11/2''(3.8 cm) from 3 remaining wires. Strip insulation back 1" (2.5 cm). Shape ends of wires into a hook shape.

When connecting to the terminal block, place the hooked end of the wire under the screw of the terminal block (hook facing right), squeeze hooked end together and tighten screw. See example below.

Place the hooked end of the neutral wire (white or center wire) of power supply cable under the center screw of terminal block (hook facing right). Squeeze hooked end together. Tighten screw.

CE

J

h

ys ¸

B

A. _" (1.9 cm) UL listed strain relief

B. Green or bare wire of power supply cable

C. External ground conductor screw

D. Center

E. Neutral wire (white or center wire)

E Neutral grounding wire (green with yellow stripes)

5= Place the hooked ends of the other power supply cable wires under the outer terminal block screws (hooks facing right). Squeeze hooked ends together. Tighten screws.

1.Remove center terminal block screw.

2.Remove neutral grounding wire (green with yellow stripes)

from external ground conductor screw. Fasten it under center,

!! !!

6.Tighten strain relief screws.

7.Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with

Use where local codes permit connecting

DE

C

A

A. External ground conductor screw - Dotted line shows

position of NEUTRAL grounding wire before being moved to center terminal block screw

B. Center

C. Green/yellow wire of harness

3= Connect ground wire (green or bare) of power supply cable to external ground conductor screw. Tighten screw.

A.

C. Neutral prong

D. Spade terminals with up turned ends E. _" (1.9 cm) UL listed strain relief

F. Ring terminals

G. Neutral (white or center wire)

10